- English

- Čeština

- Italiano

- Deutsch

- Polski

- Français

- Home

- Troubleshooting [進行中の翻訳]

- プリンタートラブルシューティング

- Nozzle Cleaning Failed (MK4, MK3.9)

Nozzle Cleaning Failed (MK4, MK3.9)

- プリント品質のトラブルシューティング

- QR Error codes [進行中の翻訳]

- プリンタートラブルシューティング

- A64 Overheat #10207 (SL1/SL1S)

- 周囲温度のチェック(MK3/MK3S)

- Ambient temperature too cold #10703 (SL1/SL1S)

- Ambient temperature too high #10702 (SL1/SL1S)

- An unexpected error has occurred #10701 (SL1)

- Another action is already running #10506 (SL1/SL1S)

- BBF Allocation Failed #17531 (XL)

- BBFの割当に失敗しました #26531 (MK4S) #13531 (MK4) #21531 (MK3.9) #23531 (MK3.5)

- BBF Initialization failed #17532 (XL)

- BBFの初期化に失敗しました #26532 (MK4S) #13532 (MK4) #21532 (MK3.9) #23532 (MK3.5)

- ヒートベッド最高温度エラー #26205 (MK4S) #13205 (MK4) #21205 (MK3.9) #23205 (MK3.5)

- ヒートベッド最低温度エラー #26207 (MK4S) #13207 (MK4) #21207 (MK3.9) #23207 (MK3.5)

- ベッドプリヒートエラー #26201 (MK4S) #13201 (MK4) #21201 (MK3.9) #23201 (MK3.5)

- ヒートベッドの熱暴走 #26203 (MK4S) #13203 (MK4) #21203 (MK3.9) #23203 (MK3.5)

- 飛んだフューズ (MINI)

- Blown Fuse (MK2S/MK2.5/MK2.5S)

- 飛んだヒューズ (MK3/MK3S/MK3S+)

- 飛んだヒューズ (MK4/S, MK3.9/S)

- Blue Screen of Death (BSOD)

- Boost board problem #10320 (SL1S)

- Bricked printer (SL1/SL1S)

- Calibration project is invalid #10543 (SL1/SL1S)

- Can't copy project #10704 (SL1/SL1S)

- Cannot get update channel #10514 (SL1)

- Cannot read project #10539 (SL1/SL1S)

- Cannot remove project #10545 (SL1/SL1S)

- ホットエンドの詰まり (MK4)

- ホットエンドの詰まり (XL)

- ノズル/ホットエンドの詰まり (MINI/MINI+)

- ノズル/ホットエンドの詰まり (MK3.5/S, MK3S+, MK2.5S)

- 接続認証の失敗

- Connect Registration Failed #12401 (MINI)

- 接続認証の失敗 #17401 (XL)

- Connect Registration Failed #21401 (MK3.9)

- Connect Registration Failed #23401 (MK3.5)

- Connect Registration Failed #26401 (MK4S) #13401 (MK4)

- Directory not empty #10546 (SL1/SL1S)

- Disconnected UV LED panel #10321 (SL1/SL1S)

- Display test failed #10120 (SL1/SL1S)

- Dwarfボードエラー #17502 (XL)

- Dwarfボードエラー #17503 (XL)

- EEPROM I2C Receive Busy #17316 (XL)

- EEPROM I2C 受信ビジー #26316 (MK4S) #13316 (MK4) #21316 (MK3.9) #23316 (MK3.5)

- Emergency stop #12510 (MINI)

- Emergency stop #17510 (XL)

- 緊急停止 #26510 (MK4S) #13510 (MK4) #21510 (MK3.9) #23510 (MK3.5)

- ESP error #17504 (XL)

- ESP error #17505 (XL)

- ESP error #17506 (XL)

- ESPエラー #26504 (MK4S) #13504 (MK4) #21504 (MK3.9) #23504 (MK3.5)

- ESPエラー #26505 (MK4S) #13505 (MK4) #21505 (MK3.9) #23505 (MK3.5)

- ESPエラー #26506 (MK4S) #13506 (MK4) #21506 (MK3.9) #23506 (MK3.5)

- ESP not connected #17533 (XL)

- Expect overheating #10714 (SL1/SL1S)

- External SPI flash W25X20CL/xFLASH が反応しない - エラー

- エクストルーダーのブロブ

- EXTRUDER ERROR #17536 (XL)

- Extruder Maxtemp error #17206 (XL)

- Extruder Mintemp error #17208 (XL)

- エクストルーダーのノイズ

- エクストルーダー プリヒートエラー #17202 (XL)

- Extruder temp not matching #17210 (XL)

- エクストルーダーの熱暴走 #17204 (XL)

- プリント途中でエクストルーダーの押し出しが止まる現象(ヒートクリープ)

- ファクトリーリセット (MINI)

- ファクトリーリセット (MK2S/MK2.5S/MK3S)

- 工場出荷時の状態へのリセット (MK4/S, MK3.9/S, MK3.5/S, XL)

- Factory Reset (MMU)

- Factory reset (MMU2S pre firmware 1.0.6)

- Factory reset (SL1/SL1S)

- Failed to read the configuration file #10505 (SL1)

- Zキャリブレーションの失敗 (MK3S/MK2.5S)

- Fan failure #10106 (SL1/SL1S)

- Fan warning #10713 (SL1/SL1S)

- フィラメントのアンロード失敗(MINI/MINI+)

- フィラメントがロードされていかない

- フィラメントがロードされない (MK4/S, MK3.9/S)

- フィラメントがロードされていかない (XL)

- フィラメントセンサー (MK4/S, MK3.9/S, XL)

- File already exists! #10520 (SL1)

- File not found #10518 (SL1/SL1S)

- File system error #12613 (MINI/MINI+)

- ファイルシステムエラー #26613 (MK4S) #13613 (MK4) #21613 (MK3.9) #23613 (MK3.5)

- FINDA setup and troubleshooting

- FINDA: Filament Stuck #04102 (MMU)

- Firmware in the internal flash corrupted! #12608 (MINI)

- Firmware missing #17612 (XL)

- Firmware Update Required #26701 (MK4S) #13701 (MK4) #21701 (MK3.9) #23701 (MK3.5)

- ファームウェアのアップデート時の問題 (MK2.5S/MK3S+/MMU2S/MMU3)

- First layer does not stick (SL1/SL1S)

- Flash erase error #12605 (MINI/MINI+)

- Flash erase error #17605 (XL)

- フラッシュ消去エラー #26605 (MK4S) #13605 (MK4) #21605 (MK3.9) #23605 (MK3.5)

- FW in internal flash corrupted #17608 (XL)

- 内蔵メモリ内のFWが破損しています #26608 (MK4S) #13608 (MK4) #21608 (MK3.9) #23608 (MK3.5)

- Hash verification failed #12607 (MINI/MINI+)

- Hash verification failed #17607 (XL)

- ハッシュの検証に失敗 #26607 (MK4S) #13607 (MK4) #21607 (MK3.9) #23607 (MK3.5)

- ヒートベッドが正常に加熱されない

- ヒートベッドポートの過電流 #26309 (MK4S) #13309 (MK4) #21309 (MK3.9) #23309 (MK3.5)

- Heatbed temp not matching #17209 (XL)

- Heatbreak Maxtemp error #17212 (XL)

- ヒートブレイク最高温度エラー #26212 (MK4S) #13212 (MK4) #21212 (MK3.9)

- Heatbreak Mintemp error #17211 (XL)

- ヒートブレイク最低温度エラー #26211 (MK4S) #13211 (MK4) #21211 (MK3.9)

- Homing Error #12301 (MINI)

- Homing error X #12304 (MINI/MINI+)

- Homing error X #17304 (XL)

- X軸ホーミングエラー #26304 (MK4S) #13304 (MK4) #21304 (MK3.9) #23304 (MK3.5)

- Homing error Y #12305 (MINI/MINI+)

- Homing error Y #17305 (XL)

- Y軸ホーミングエラー #26305 (MK4S) #13305 (MK4) #21305 (MK3.9) #23305 (MK3.5)

- Zホーミングエラー #17301 (XL)

- Homing Error Z #23301 (MK3.5)

- Z軸ホーミングエラー #26301 (MK4S) #13301 (MK4) #21301 (MK3.9)

- ホットエンドファンが回転しない

- Hotend Heater Overcurrent #17322

- Hotend maxtemp error #23206 (MK3.5)

- Hotend mintemp error #23208 (MK3.5)

- ホットエンド最低温度エラー #26208 (MK4S) #13208 (MK4) #21208 (MK3.9)

- Hotend preheat error #23202 (MK3.5)

- ホットエンドプリヒートエラー #26202 (MK4S) #13202 (MK4) #21202 (MK3.9)

- Hotend temp not matching #13210 (MK3.9/MK4)

- Hotend temp not matching #23210 (MK3.5)

- Hotend thermal runaway #23204 (MK3.5)

- ホットエンドの熱暴走 #26204 (MK4S) #13204 (MK4) #21204 (MK3.9)

- I2C Receive failed #17315 (XL)

- I2C受信の失敗 #13315 #26315 (MK4S)(MK4) #21315 (MK3.9) #23315 (MK3.5)

- I2C Receive Timeout #17317 (XL)

- I2C受信のタイムアウト #26317 (MK4S) #13317 (MK4) #21317 (MK3.9) #23317 (MK3.5)

- I2C Receive undefined #17318 (XL)

- I2C受信の未定義 #26318 (MK4S) #13318 (MK4) #21318 (MK3.9) #23318 (MK3.5)

- I2C Send Busy #17312 (XL)

- I2C 送信ビジー #26312 (MK4S) #13312 (MK4) #21312 (MK3.9) #23312 (MK3.5)

- I2C Send Failed #17311 (XL)

- I2C送信の失敗 #26311 (MK4S) #13311(MK4) #21311 (MK3.9) #23311 (MK3.5)

- I2C Send Timeout #17313 (XL)

- I2C送信のタイムアウト #26313 (MK4S) #13313(MK4) #21313 (MK3.9) #23313 (MK3.5)

- I2C Send Undefined #17314 (XL)

- I2C送信の未定義 #26314 (MK4S) #13314 (MK4) #21314 (MK3.9) #23314 (MK3.5)

- Imposter! Fake signature #17606 (XL)

- Incorrect printer model #10705 (SL1/SL1S)

- Internal memory full #10516 (SL1/SL1S)

- Invalid API key #10405 (SL1/SL1S)

- Invalid FW size on USB #12603 (MINI/MINI+)

- USBのFWサイズが無効 #26603 (MK4S) #13603 (MK4) #21603 (MK3.9) #23603 (MK3.5)

- Invalid FW size on USB flash drive #17603 (XL)

- IR filament sensor calibration (MMU3, MMU2S)

- IRフィラメントセンサーのトラブルシューティング(MINI/MINI+)

- IRフィラメントセンサーのトラブルシューティング(MK2.5S, MK3S)

- LCDスクリーンが機能しない

- LED Memory Error #17529 (XL)

- LEDメモリーエラー #26529 (MK4S) #13529 (MK4) #21529 (MK3.9) #23529 (MK3.5)

- Live Z adjust not saving

- Load to extruder failed #04108 (MMU)

- Loadcell Bad Configuration #17527 (XL)

- ロードセルのキャリブレーション不良 #26527 (MK4S) #13527 (MK4) #21527 (MK3.9)

- Loadcell measure failed #17526 (XL)

- ロードセル測定の失敗 #26526 (MK4S) #13526 (MK4) #21526 (MK3.9)

- Loadcell not calibrated #17523 (XL)

- ロードセル未キャリブレーション #26523 (MK4S) #13523 (MK4) #21523 (MK3.9)

- Loadcell tare error #17524 (XL)

- Loadcell Tare Error #26524 (MK4S) #13524 (MK4) #21524 (MK3.9)

- Loadcell tare failed #17525 (XL)

- ロードセル基準値の設定失敗 #26525 (MK4S) #13525 (MK4) #21525 (MK3.9)

- Loadcell timeout #17528 (XL)

- ロードセルのタイムアウト #26528 (MK4S) #13528 (MK4) #21528 (MK3.9)

- Loadcell troubleshooting

- Logging data over serial line (MMU2S)

- Loud noises from printer (SL1/SL1S)

- M.I.N.D.A./SuperPINDA センサーのテスト (MINI/MINI+)

- Marlin Request Timeout #17530 (XL)

- Marlin Request Timeout #26530 (MK4S) #13530 (MK4) #21530 (MK3.9) #23530 (MK3.5)

- Mask noavail warning #10709 (SL1/SL1S)

- ヒートベッドの温度エラー/Maxtemp error bed #12205 (MINI)

- ホットエンドの温度エラー/Maxtemp error print head #12208 (MINI)

- MCU Maxtemp Error #17213 (XL)

- ヒートベッドの温度エラー/Mintemp error bed #12207 (MINI)

- ホットエンドの温度エラー/Mintemp error print head #12208 (MINI)

- Misaligned PINDA Sensor (MK2/S)

- Missing parts (SL1/SL1S)

- MK3Sがフィラメント交換を促し続ける

- MMU MCU Underpower #04307 (MMU)

- MMU Overcurrent #26310 (MK4S) #13310 (MK4) #21310 (MK3.9) #23310 (MK3.5)

- MMU2S idler unable to move freely

- MMU2S LEDs meaning

- MMU2S Selector not moving

- Modular bed error #17250 (XL)

- Modular bed error #17251 (XL)

- Modular bed error #17252 (XL)

- Modular bed error #17253 (XL)

- Modular bed error #17254 (XL)

- モジュラーベッド エラー #17255 (XL)

- Modular bed error #17256 (XL)

- Modular bed error #17257 (XL)

- Modular bed error #17302 (XL)

- Modular bed error #17303 (XL)

- Modular Bed Error #17319 (XL)

- Modular Bed Error #17320 (XL)

- Modular bed error #17501 (XL)

- Multimeter usage

- No file on USB #12604 (MINI/MINI+)

- No file to reprint #10508 (SL1)

- No FW in internal flash #12612 (MINI/MINI+)

- 内蔵フラッシュ内にFWが存在しない #26612 (MK4S) #13612 (MK4) #21612 (MK3.9) #23612 (MK3.5)

- USBにファームウェアがありません #26604 (MK4S) #13604 (MK4) #21604 (MK3.9) #23604 (MK3.5)

- No FW on USB flash drive #17604 (XL)

- Not connected to network #10402 (SL1/SL1S)

- Not enough layers #10540 (SL1/SL1S)

- Not enough resin #10706 (SL1/SL1S)

- Nozzle Cleaning Failed (MK4, MK3.9)

- How to fix it

- ノズルクリーニングの失敗 (XL)

- ノズルがヒートベッドに衝突する

- Nozzle Heater Overcurrent #23308 (MK3.5)

- ノズルヒーターへの過電流 #26308 (MK4S) #13308 (MK4) #21308 (MK3.9)

- Object cropped warning #10710 (SL1/SL1S)

- Opening project failed #10504 (SL1/SL1S)

- Out of memory #17507 (XL)

- メモリー切れ #26507 (MK4S) #13507 (MK4) #21507 (MK3.9) #23507 (MK3.5)

- M.I.N.D.A./SuperPINDA センサーのテスト (MINI/MINI+)

- Parameters out of range #10707 (SL1/SL1S)

- ピンが未到達 #17107 (XL)

- PNG Buffer Full #17508 (XL)

- PNGバッファのメモリ不足 #26508 (MK4S) #13508 (MK4) #21508 (MK3.9) #23508 (MK3.5)

- ベッドのプリヒートエラー #12201 (MINI)

- ホットエンドのプリヒートエラー/Preheat error print head #12202 (MINI)

- Preload failed #10503 (SL1/SL1S)

- Print examples missing #10523 (SL1/SL1S)

- プリントファンが回転していません

- プリンタの電源が入らない、または電源が切れたままになる

- Project analysis failed #10542 (SL1/SL1S)

- Project is corrupted #10541 (SL1/SL1S)

- PrusaLinkのトラブルシューティング

- Puppy error #17511 (XL)

- Puppy error #17512 (XL)

- パピーエラー #17513 (XL)

- パピーエラー #17514 (XL)

- Puppy error #17515 (XL)

- Puppy error #17516 (XL)

- Puppy error #17517 (XL)

- Puppyボードエラー #17518 (XL)

- Puppy error #17519 (XL)

- Puppy error #17520 (XL)

- Puppy error #17521 (XL)

- Puppy error #17522 (XL)

- Remote API error #10407 (SL1/SL1S)

- Resin low #10712 (SL1/SL1S)

- Resin measuring failed #10124 (SL1/SL1S)

- Resin sensor error #10307 (SL1/SL1S)

- Resin too high #10109 (SL1/SL1S)

- Resin too low #10108 (SL1/SL1S)

- Sample G-codes

- Saving log file (SL1/SL1S)

- SDカードが読めません

- SDカード・USBメモリ

- Selftest failed (XL multi-tool)

- セルフテストの失敗 (XL)

- Signature verification failed #12606 (MINI/MINI+)

- 署名の検証に失敗 #26606 (MK4S) #13606 (MK4) #21606 (MK3.9) #23606 (MK3.5)

- SL1 Tilt-mechanism error

- スパゲッティモンスター

- MINIを正確に調整する

- ステータスLEDについて (MK4/XL)

- Status LED explained (MMU3)

- フィラメントスタックの検出 #26101 (MK4S) #13101 (MK4) #21101 (MK3.9) #17108 (XL)

- Tangled filament

- Temp not matching heatbed #12209 (MINI/MINI+)

- Temp not matching print head #12210 (MINI/MINI+)

- Temperature out of range #10208 (SL1/SL1S)

- Thermal runaway(ヒートベッド) #12203 (MINI)

- Thermal runaway(プリントヘッド) #12204 (MINI)

- TMC driver shorted #04304 (MMU)

- TMC driver shorted #04314 (MMU)

- TMC driver shorted #04324 (MMU)

- ツールオフセットが不整合 #17104 (XL)

- ツールチェンジャーエラー #17101 (XL)

- Toolchanger problem (XL multi-tool)

- Tower check failed #10118 (SL1/SL1S)

- Unauthorized #10406 (SL1/SL1S)

- Under-extrusion (Nextruder printers)

- Unexpected error #10501 (SL1/SL1S)

- Unexpected MC error #10306 (SL1/SL1S)

- Unknown printer model #10323 (SL1/SL1S)

- Unsupported BBF version #12614 (MINI/MINI+)

- サポートされていないBBFバージョン #26614 (MK4S) #13614 (MK4) #21614 (MK3.9) #23614 (MK3.5)

- Unsupported Buddy FW #17611 (XL)

- Unsupported firmware BBF file #17614 (XL)

- Unsupported printer model #17610 (XL)

- Unsupported printer type #12610 (MINI/MINI+)

- サポートされていないプリンタタイプ #26610 (MK4S) #13610 (MK4) #21610 (MK3.9) #23610 (MK3.5)

- Unsupported printer version #12611 (MINI/MINI+)

- サポートされていないプリンタバージョン #26611 (MK4S) #13611 (MK4) #21611 (MK3.9) #23611 (MK3.5)

- USB Device Overcurrent #17307 (XL)

- USBデバイスの過電流 #26307 (MK4S) #13307 (MK4) #21307 (MK3.9) #23307 (MK3.5)

- USB drive not detected #10528 (SL1/SL1S)

- USB flash drive not connected #17602 (XL)

- USB flash error #17613 (XL)

- USB not connected #12602 (MINI/MINI+)

- USBメモリが接続されていません #26602 (MK4S) #13602 (MK4) #21602 (MK3.9) #23602 (MK3.5)

- USB Port Overcurrent #17306 (XL)

- USBポートの過電流 #26306 (MK4S) #13306 (MK4) #21306 (MK3.9) #23306 (MK3.5)

- UV LED temperature error #10209 (SL1/SL1S)

- UV led voltage error #10309 (SL1)

- プリント中の振動とノイズ (MK3S+/MK2.5S)

- Wrong printer model #10544 (SL1/SL1S)

- Wrong revision of motion controller #10301 (SL1)

- XY position invalid #17106 (XL)

- XY probe unstable #17105 (XL)

- プリントエラーメッセージ

To achieve good quality prints, it is fundamental that the nozzle can make the right amount of contact with the print surface. In case this is not achieved, the Original Prusa MK4 or MK3.9 will show the message "nozzle cleaning failed".

How to fix it

Nozzle cleaning

Check if the nozzle has residue. Debris on the nozzle or heater block can affect its thermal properties. To clean it, heat the nozzle for three to five minutes at 250 °C, as the remains of the filament must be warmed up slightly so that they can be removed more easily.

Use a small brass brush to clear away any old plastic stuck on the nozzle and heaterblock.

Caution: the printer is still at a hot temperature! Wait until the hot parts are cooled down to ambient temperature. It takes approximately 10 minutes. Do not touch it! Always check the values on the display.

Steel sheet cleaning

Make sure that the steel sheet is clean of any residue. For the smooth, textured, or satin sheet, clean with 90% or higher percentage isopropyl alcohol (IPA).

Check if the nozzle is not loose

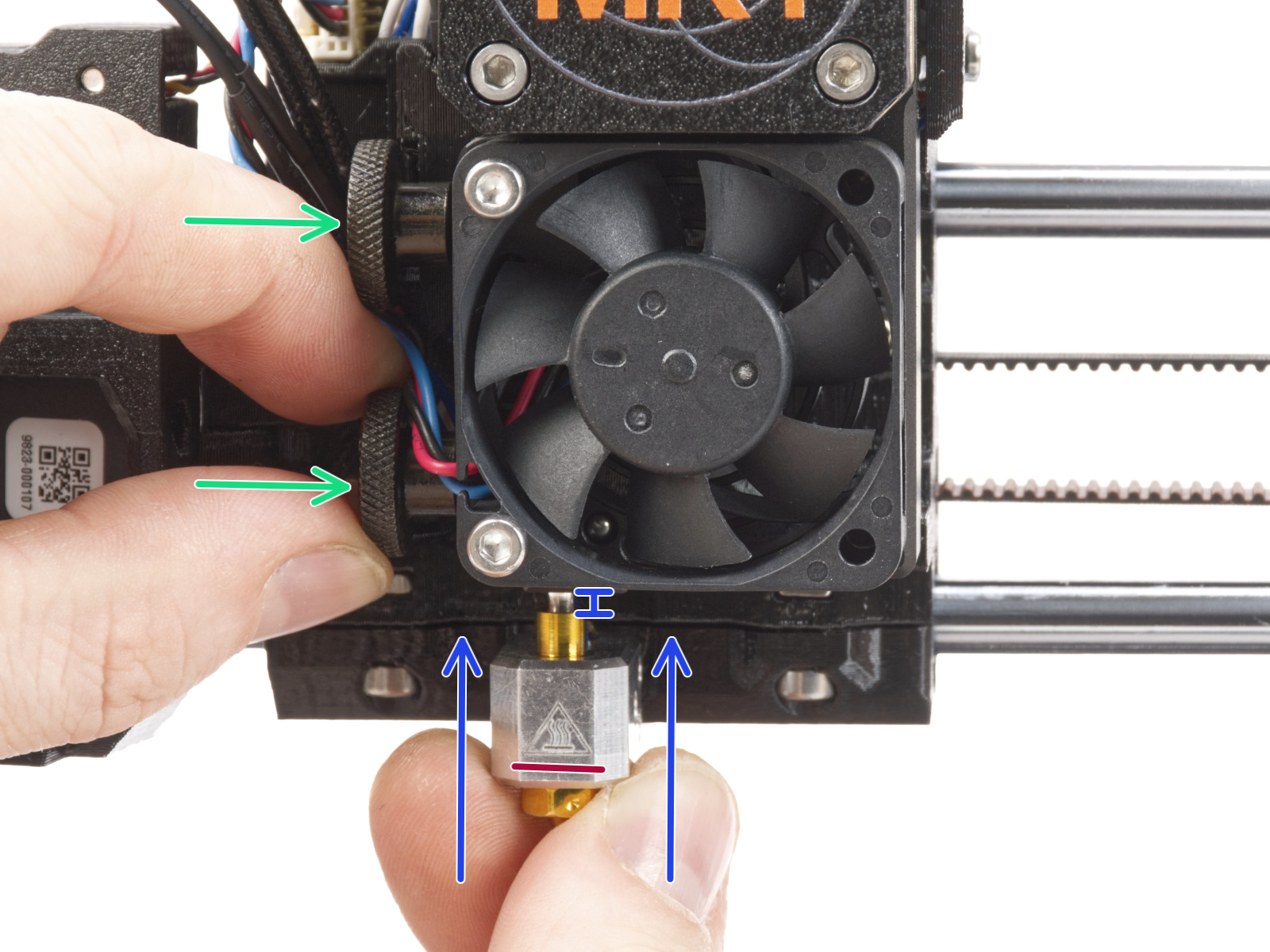

The nozzle on the Nextruder has to be at the correct height and tightened. To check this aspect, loosen the thumb screws (do not completely remove the screws, a few turns are enough) on the side of the heatbreak, and push the nozzle up. Tighten the thumb screws just by hand, do not use any tools.

If you have a Nozzle Adapter, check the installation again to make sure that the nozzle has not been lowered or loosened with the installation of the adapter.

Check the bolts that interact with loadcell

Some of the Nextruder bolts, if too tight, might generate extra forces that can be sensed by the loadcell, skewing its readings, hence potentially causing the issue. Check if slightly loosening the following bolts, while having the parts still tight and secured in place, can solve the issue:

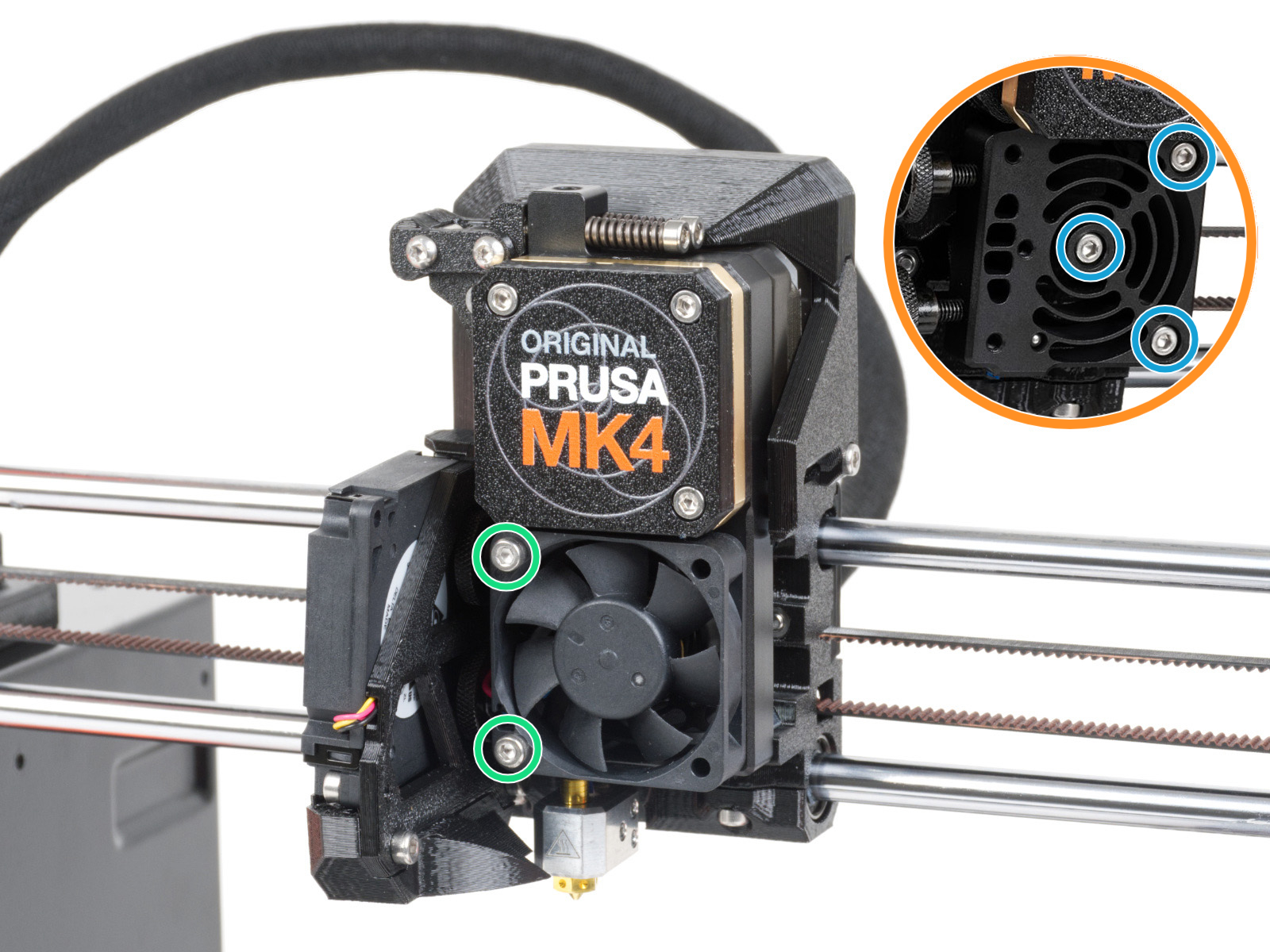

- Slightly loosen the two bolts holding the hotend fan. If this doesn't solve the issue, proceed to the next step.

- Temporarily remove the hotend fan by removing the previously adjusted bolts. This will expose the heatsink/loadcell. Then, loosen very slightly the three bolts that hold the heatsink/loadcell in place.

Comments

Still have questions?

If you have a question about something that isn't covered here, check out our additional resources.

And if that doesn't do the trick, you can send an inquiry to [email protected] or through the button below.