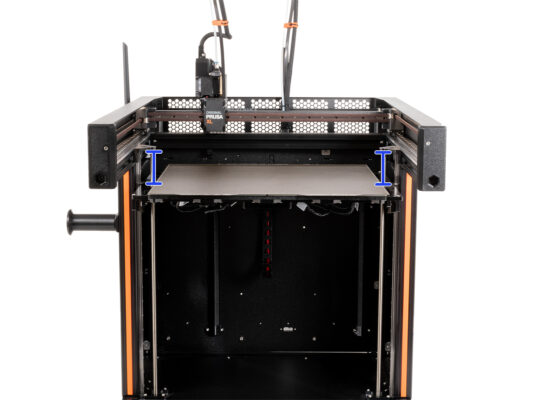

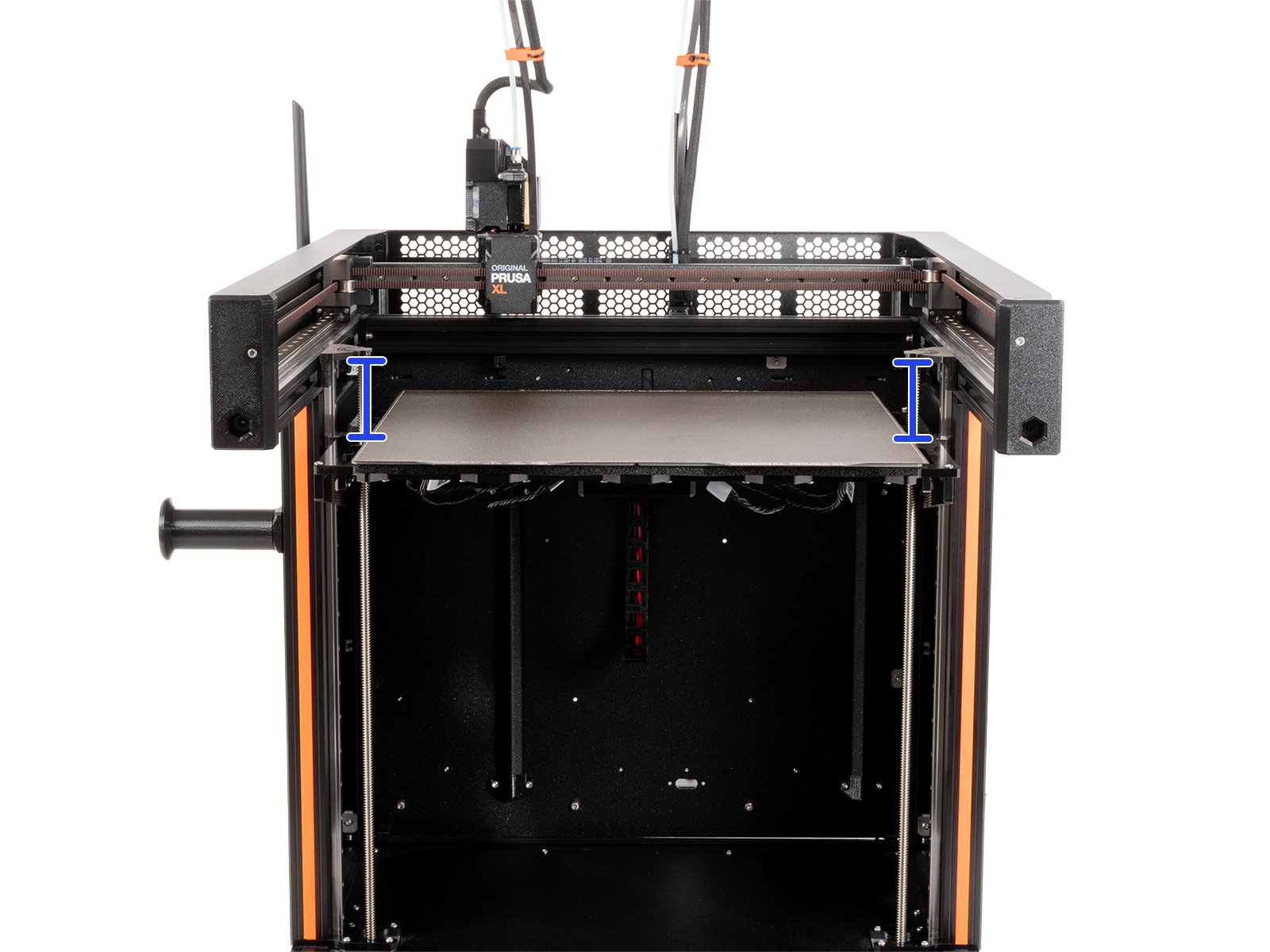

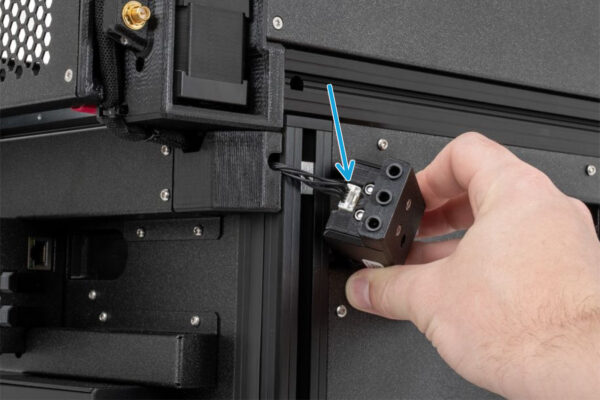

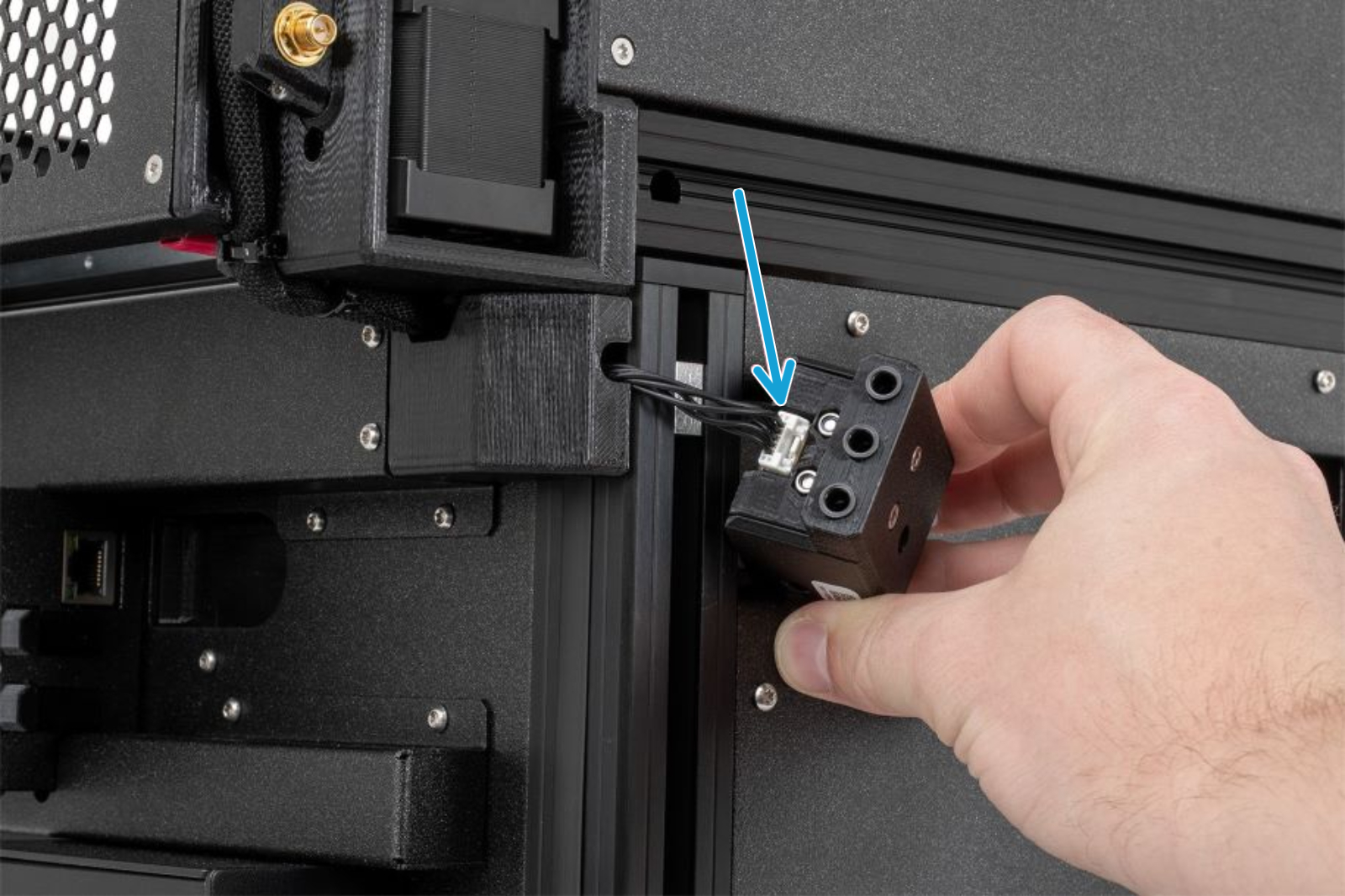

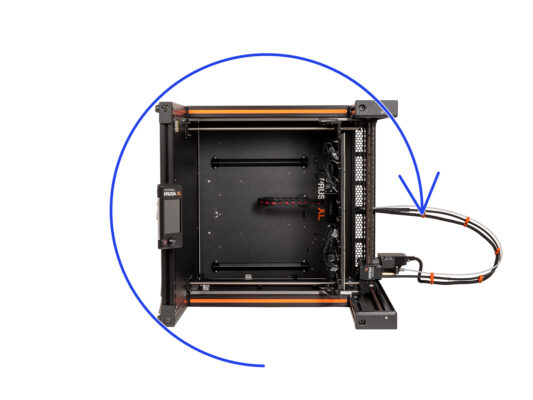

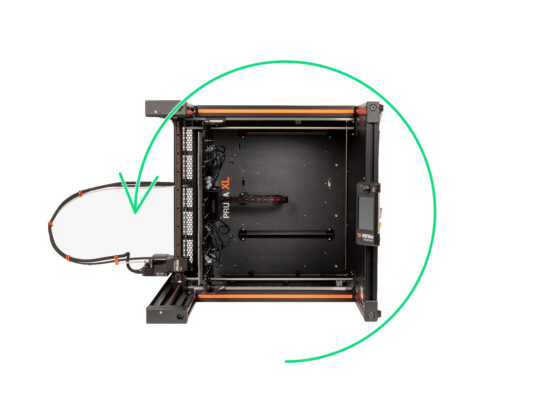

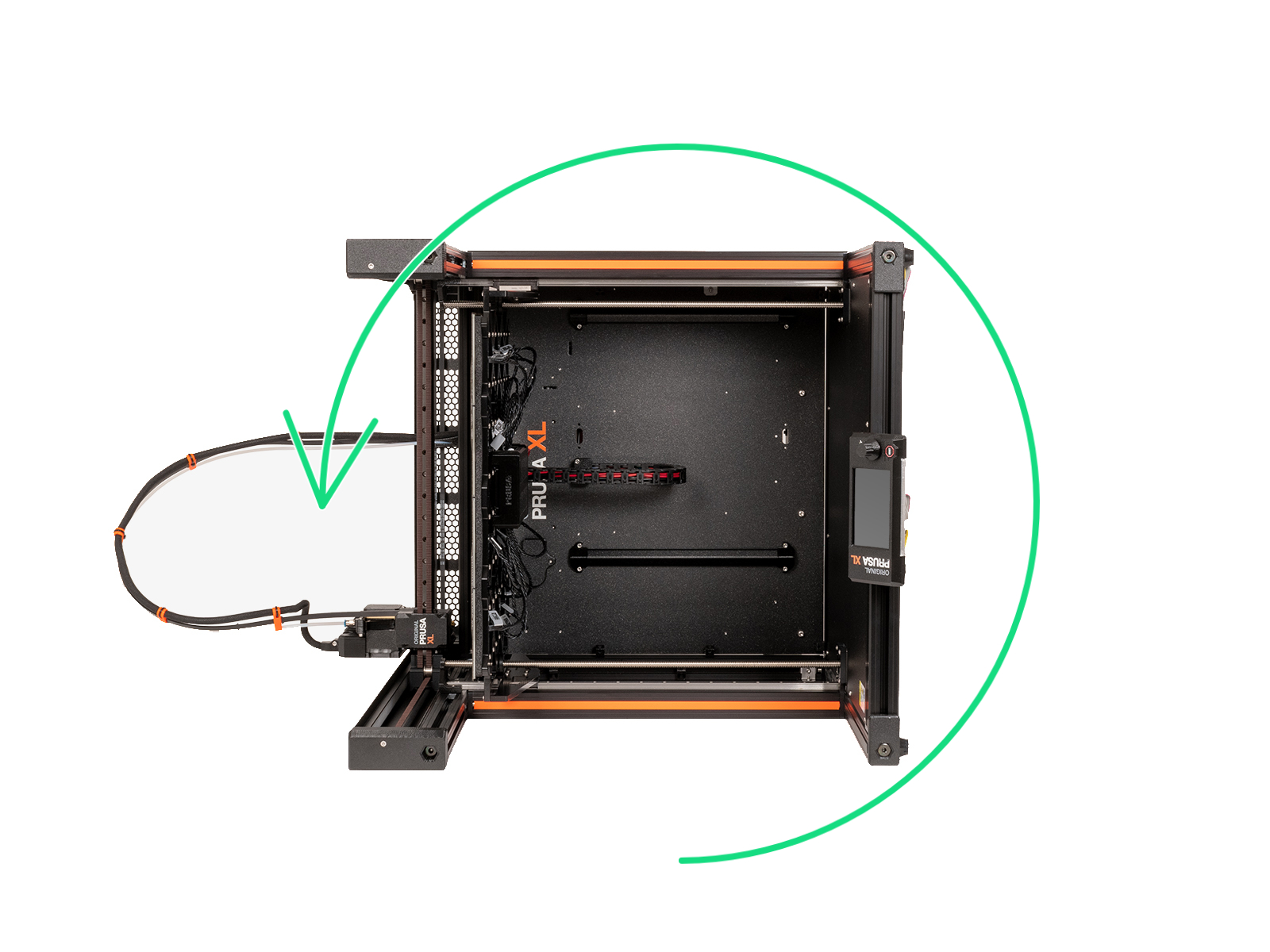

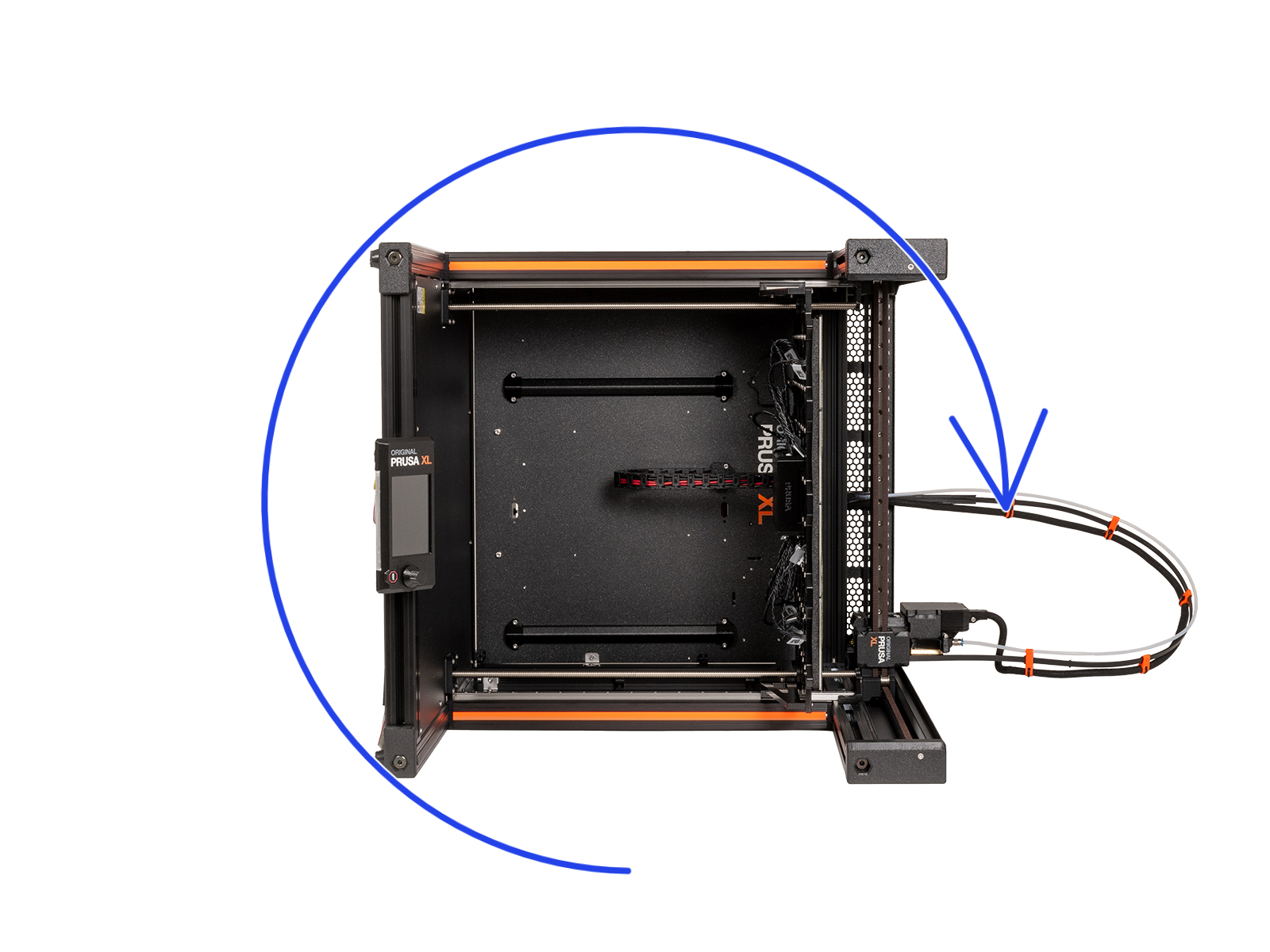

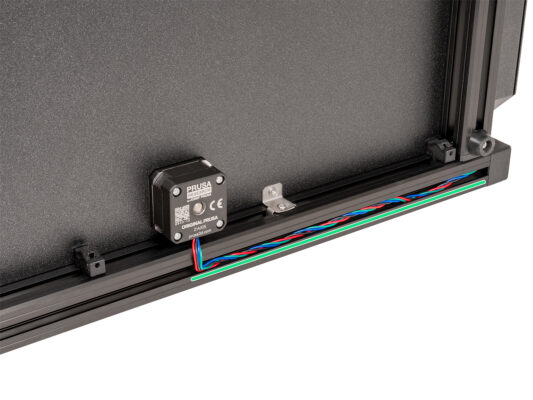

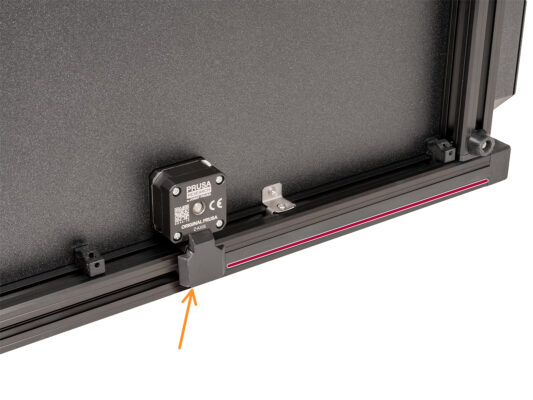

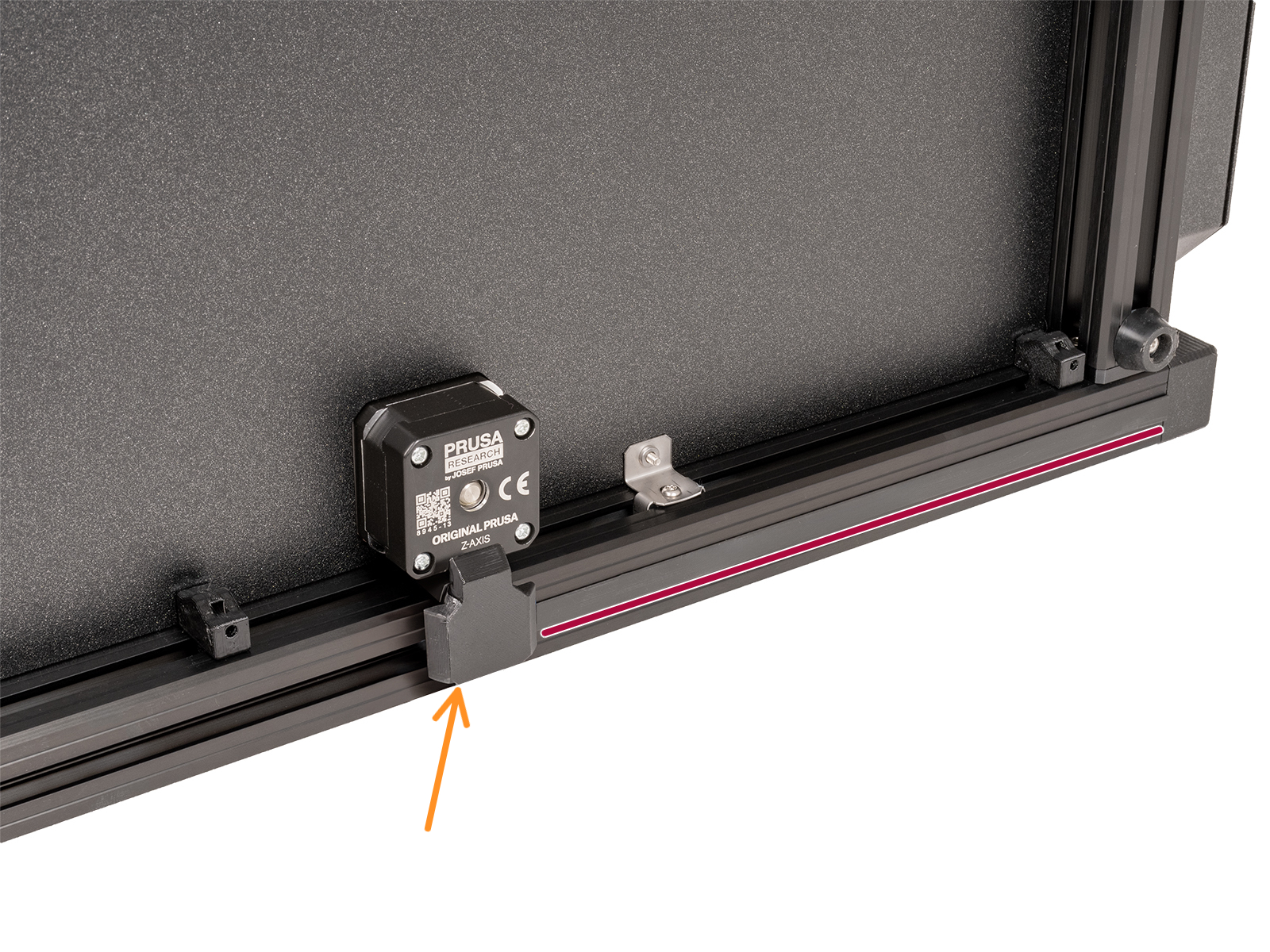

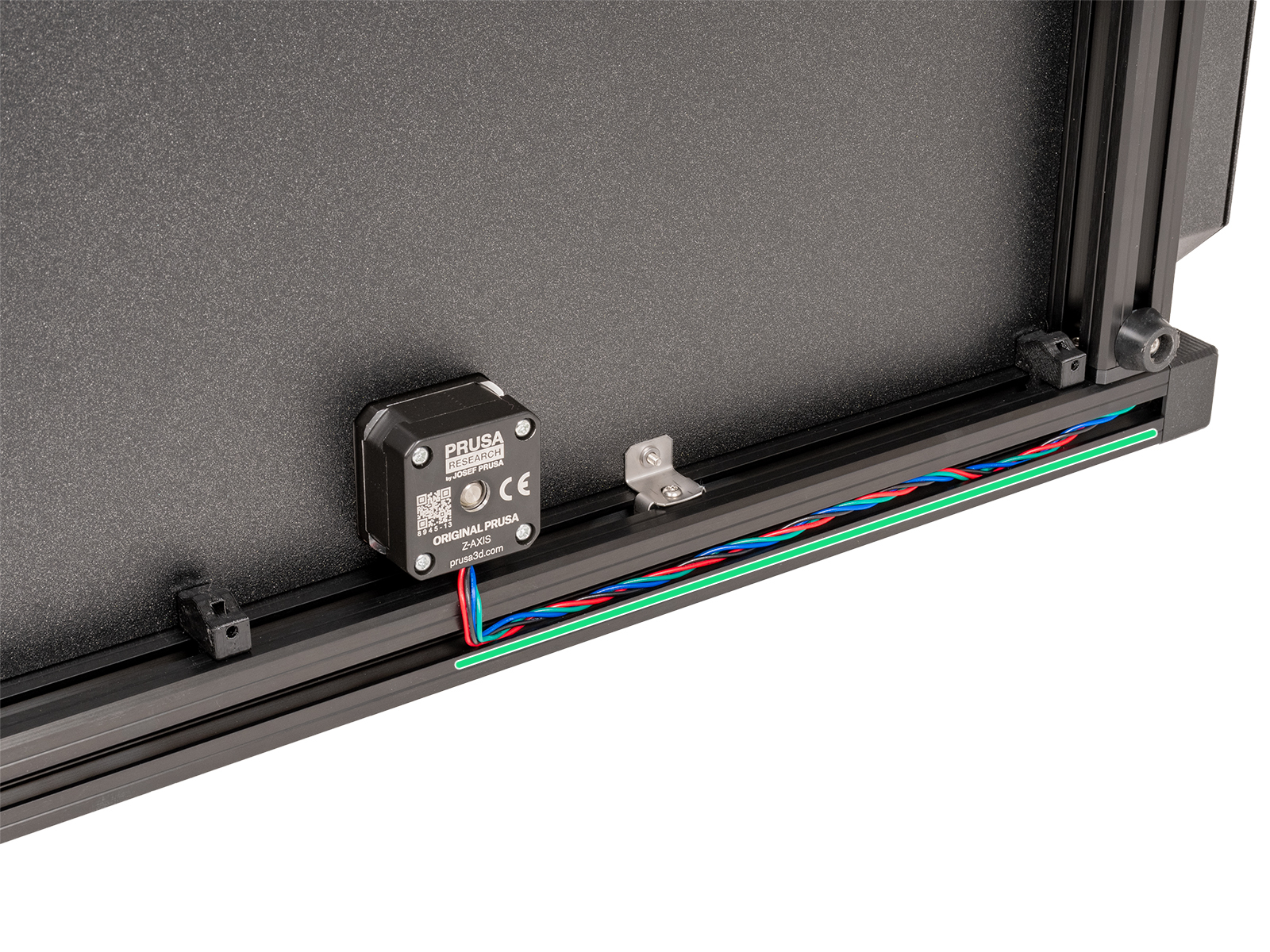

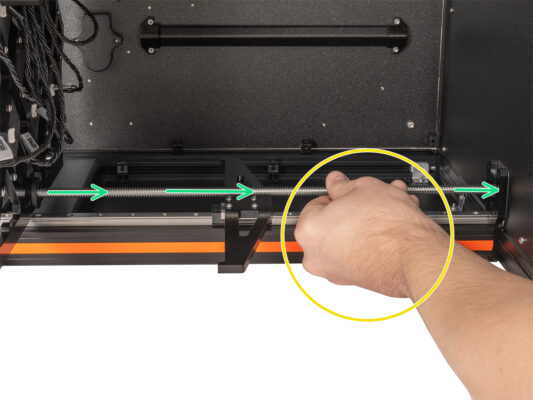

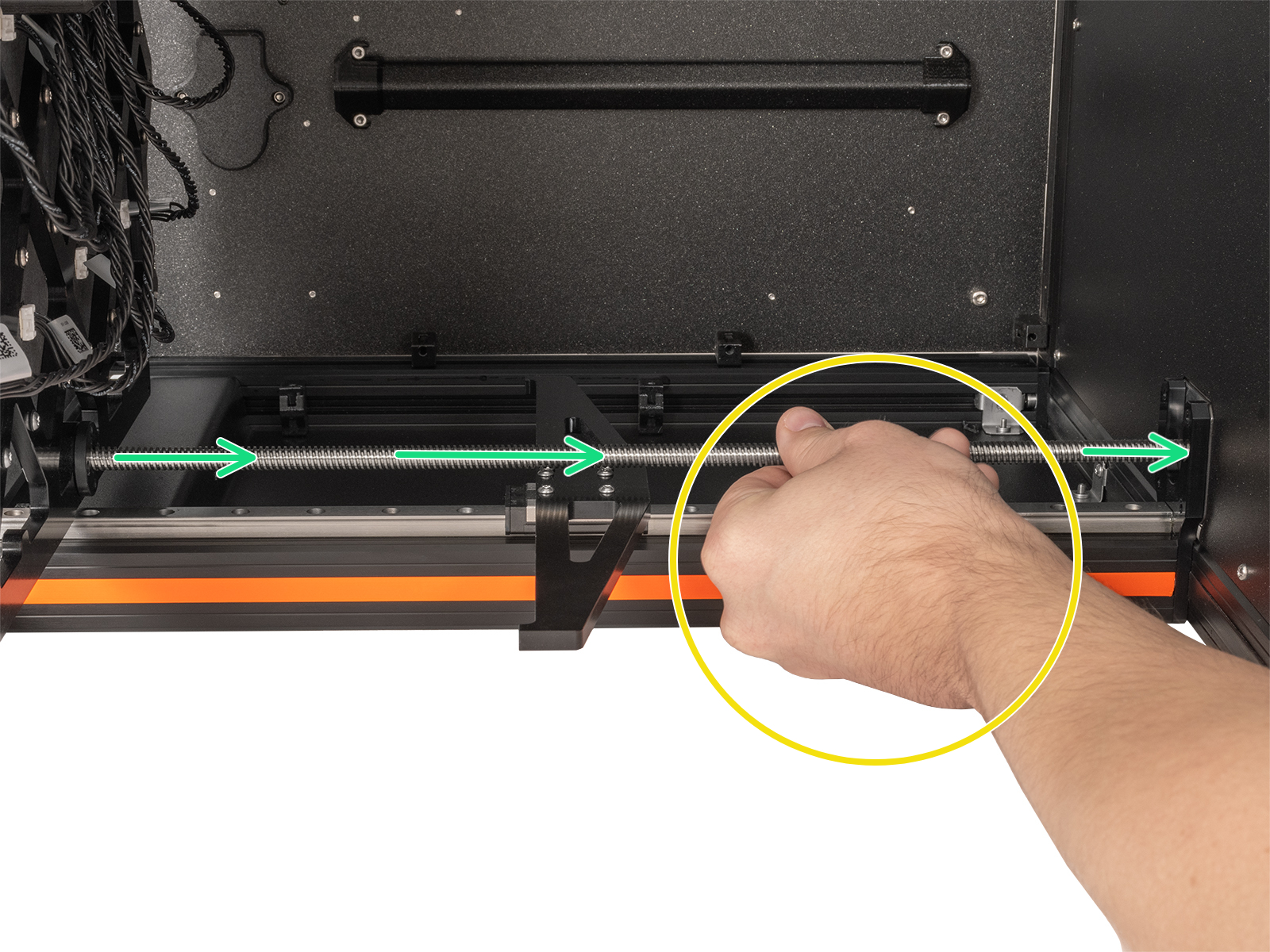

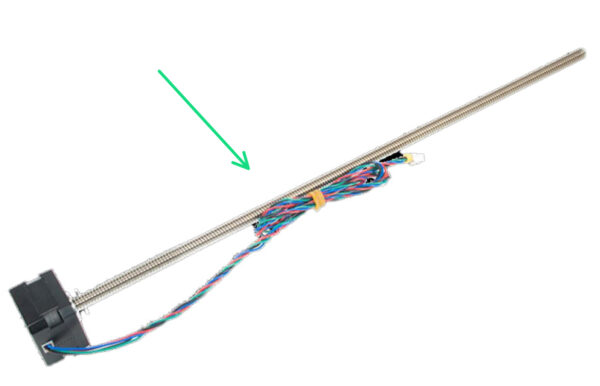

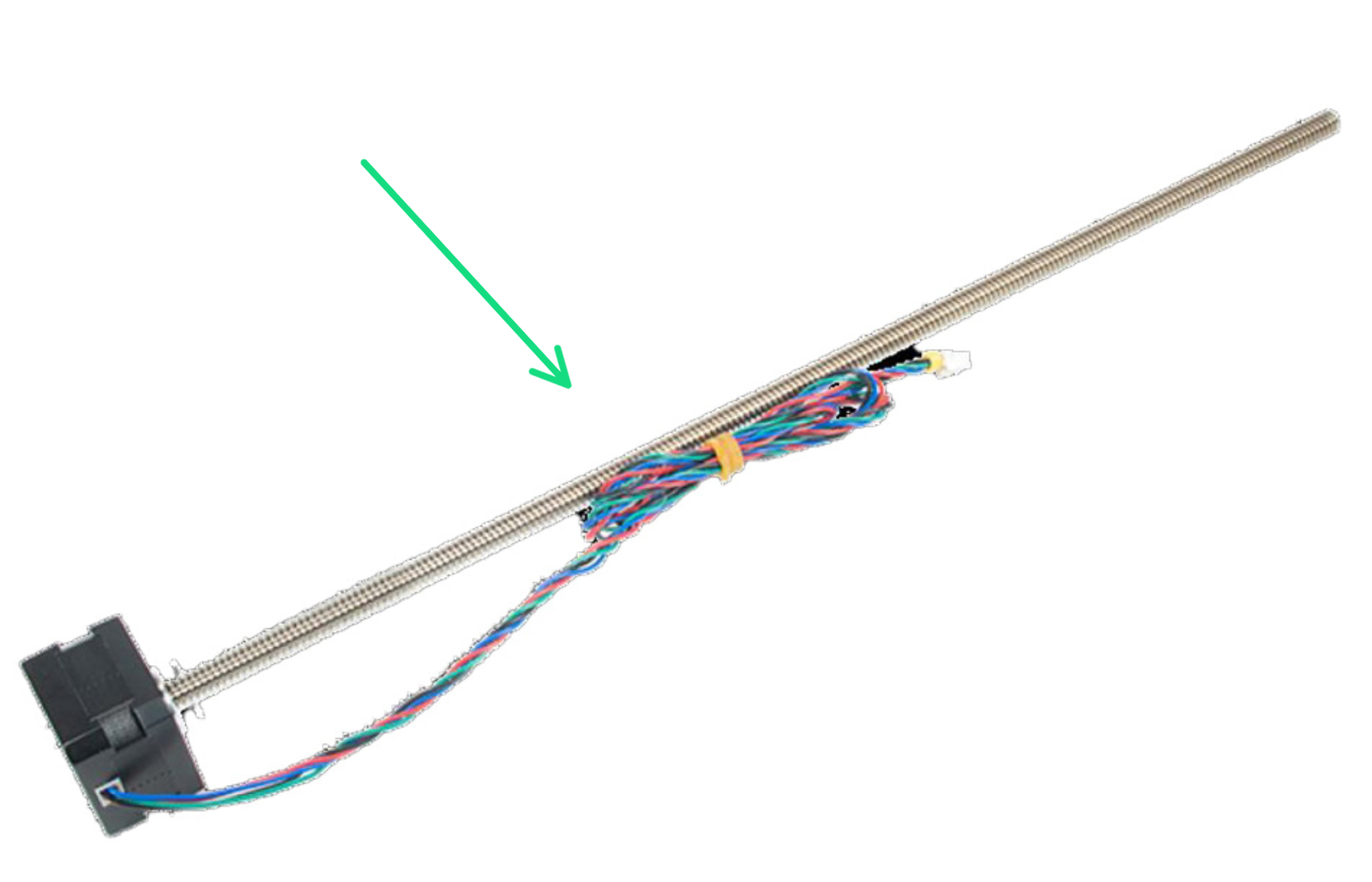

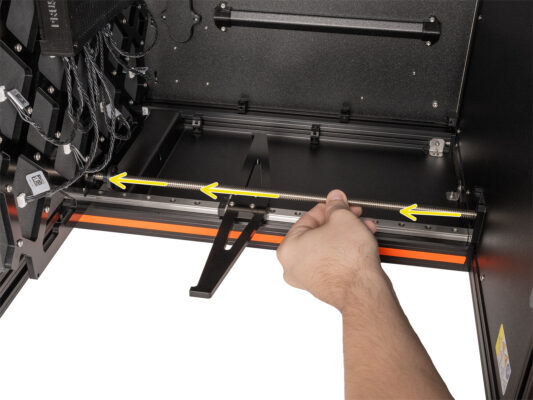

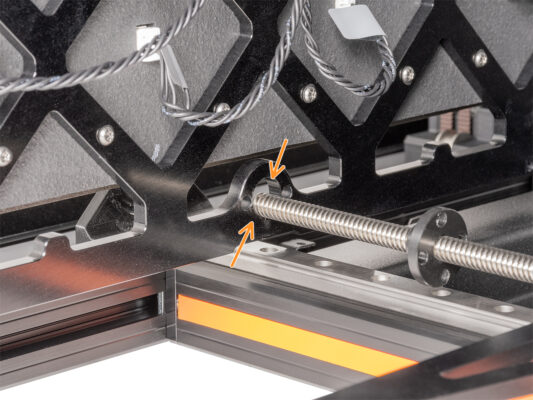

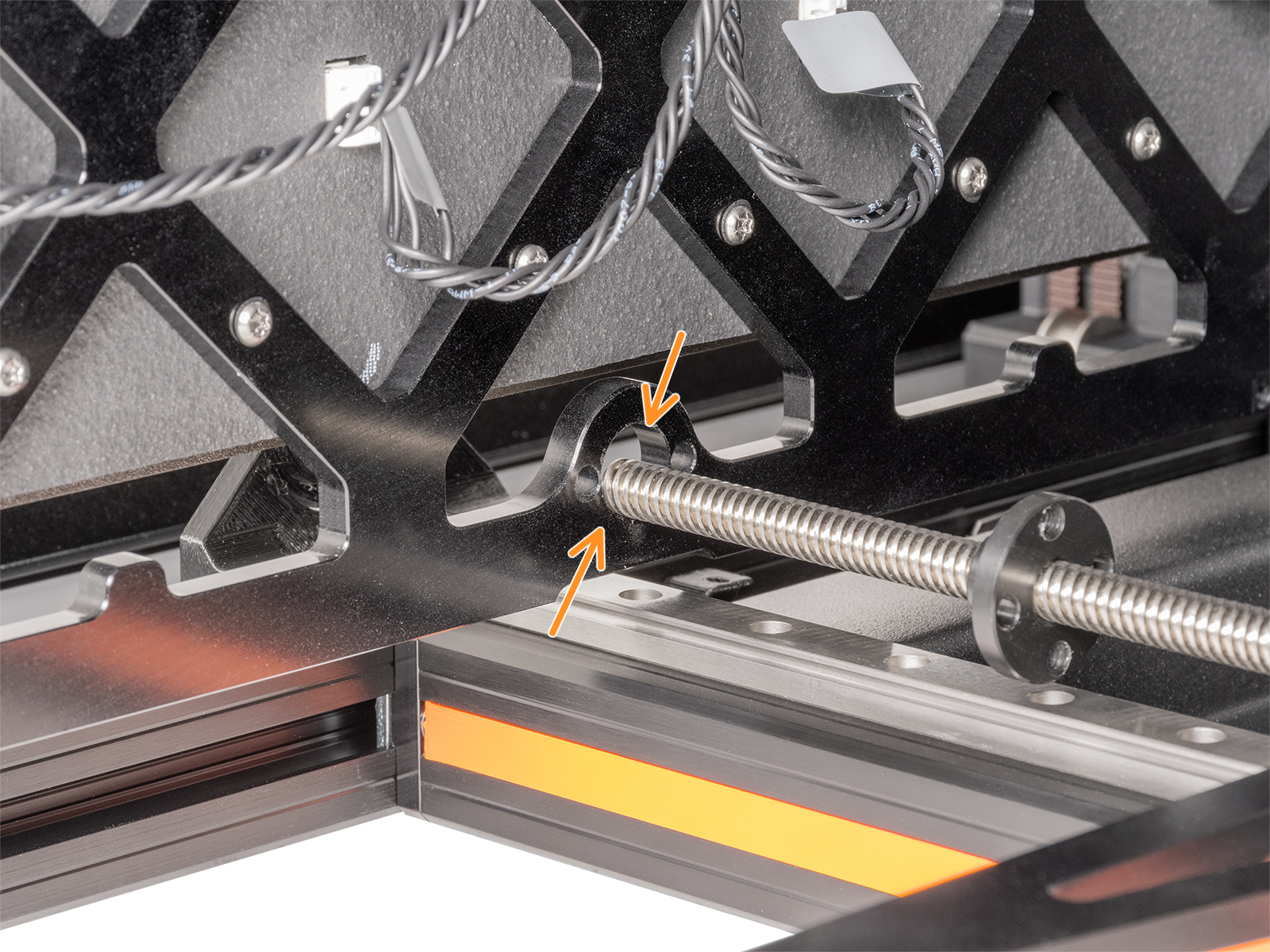

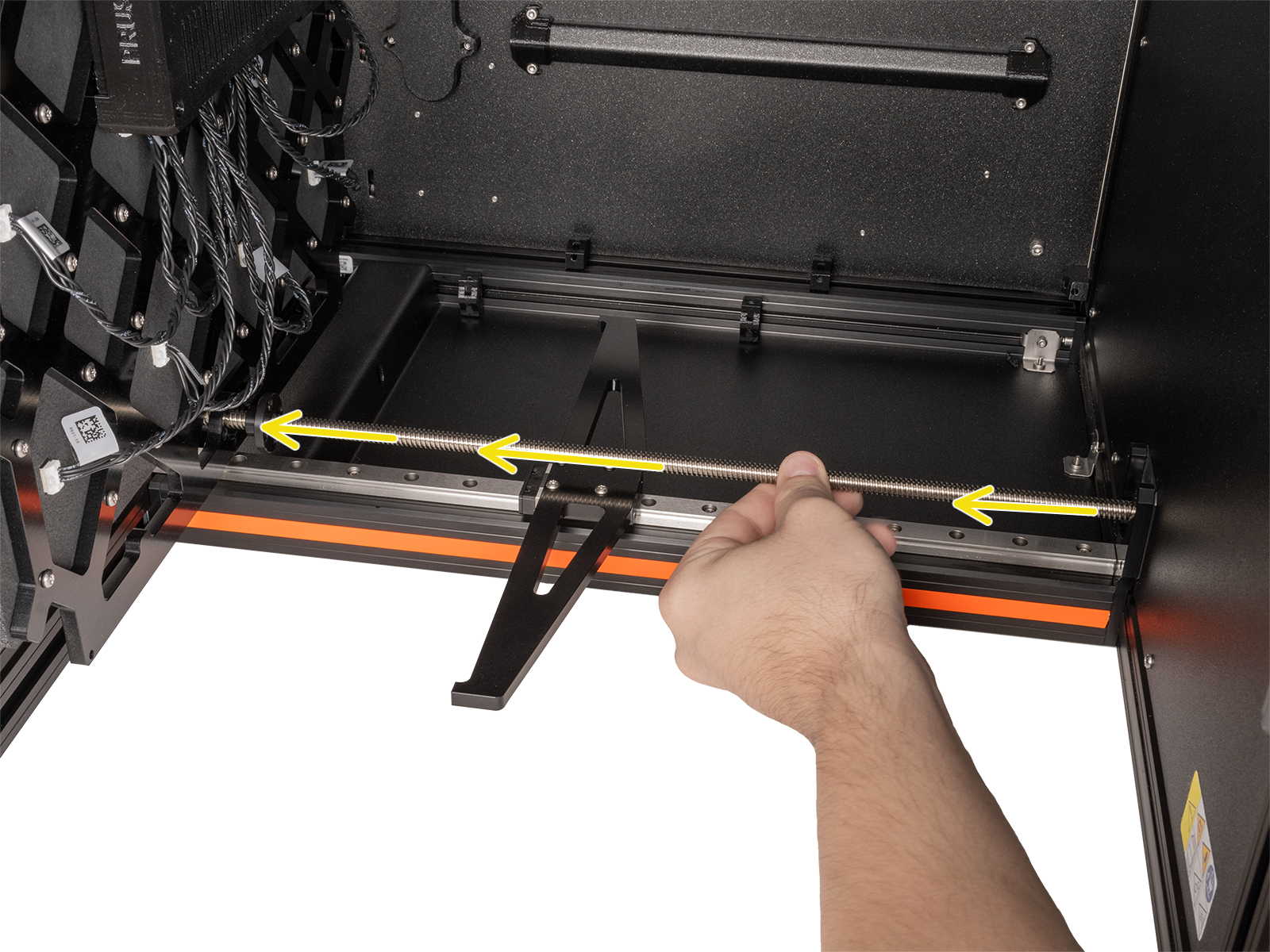

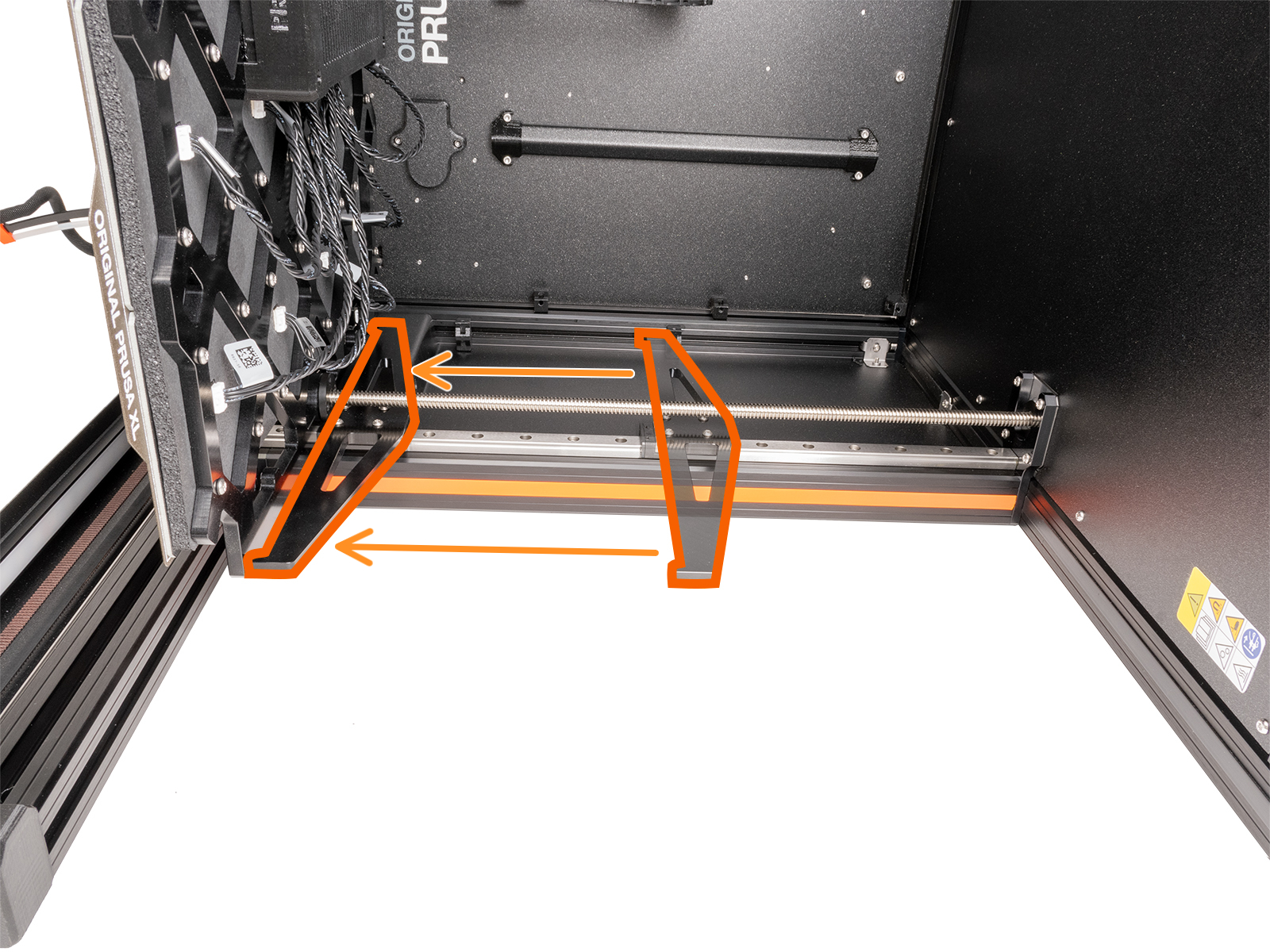

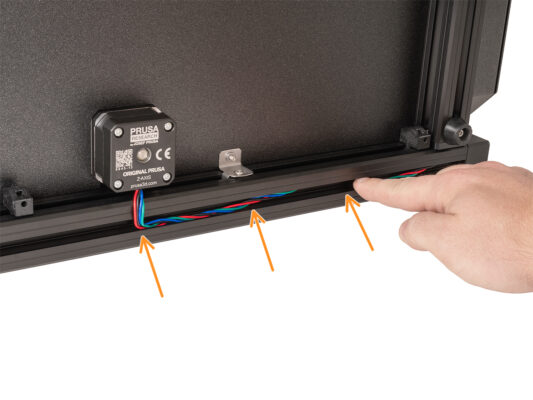

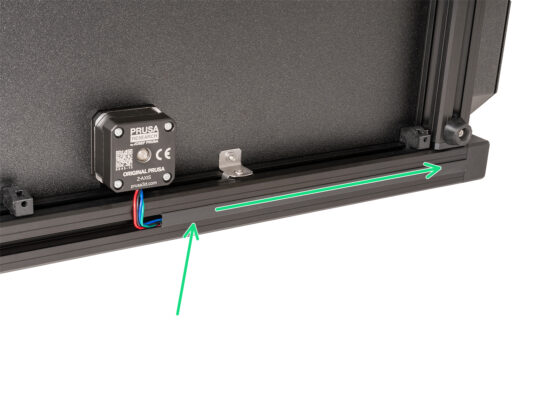

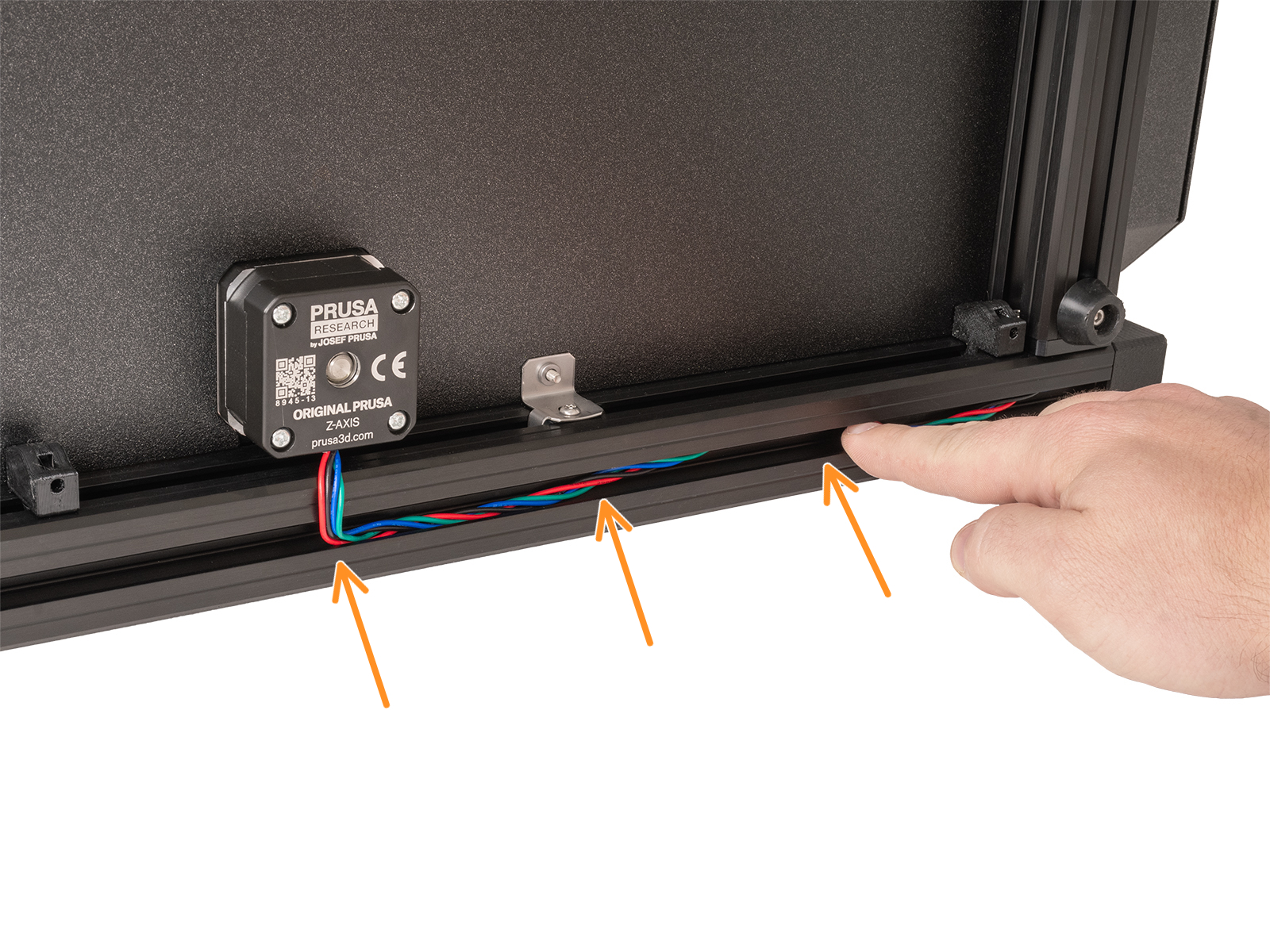

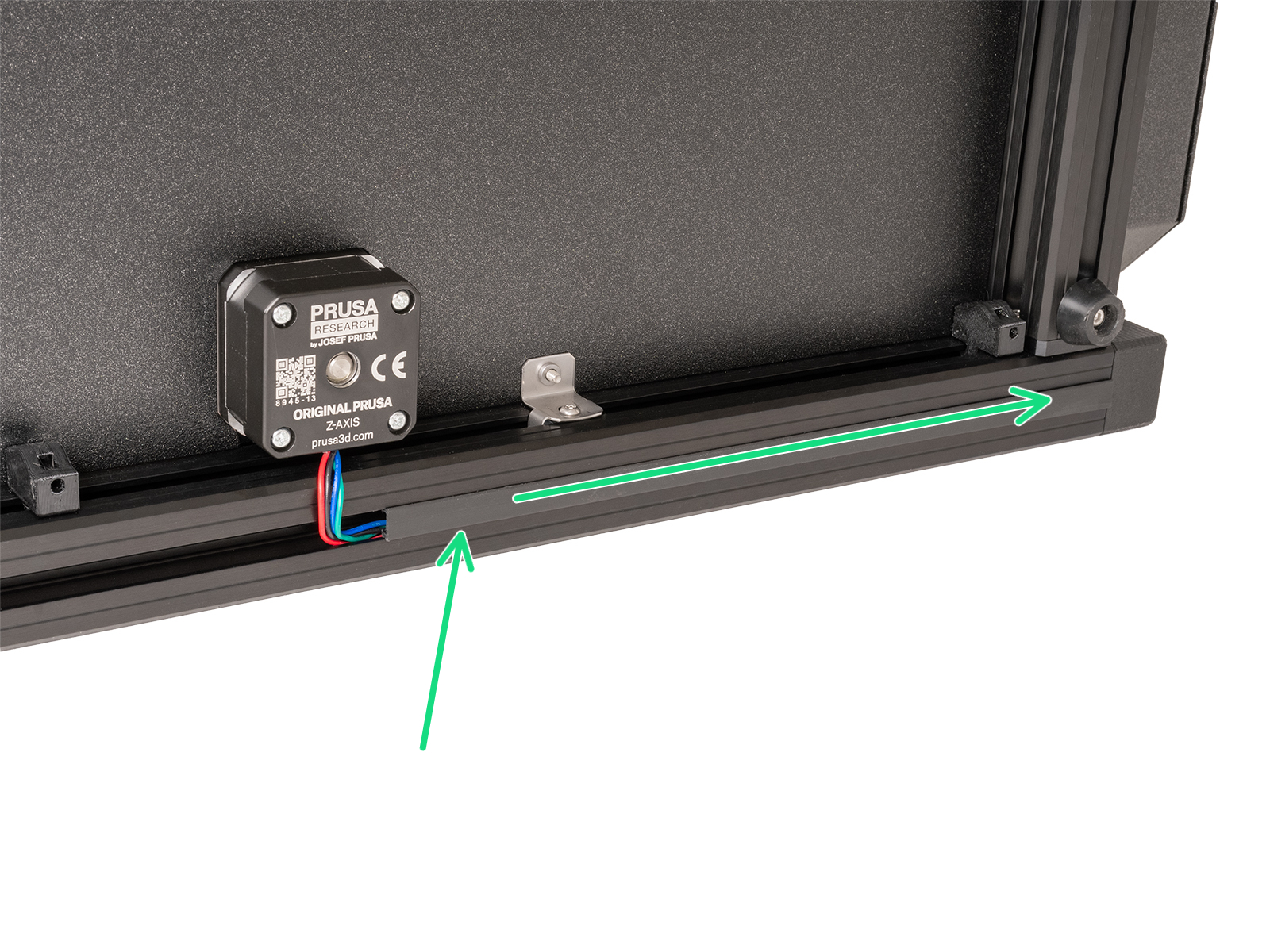

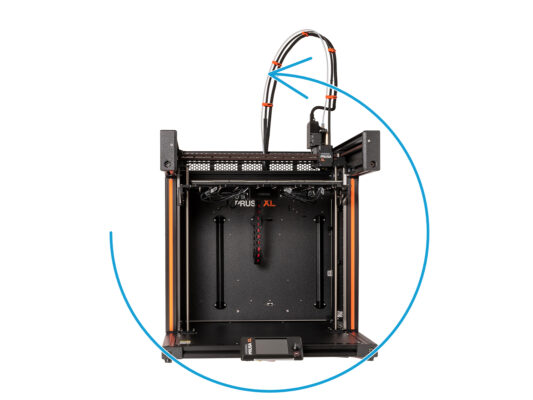

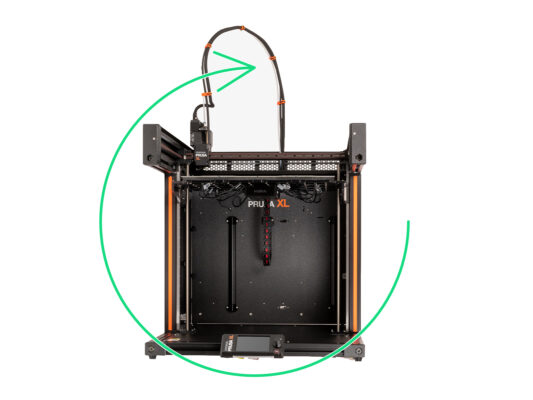

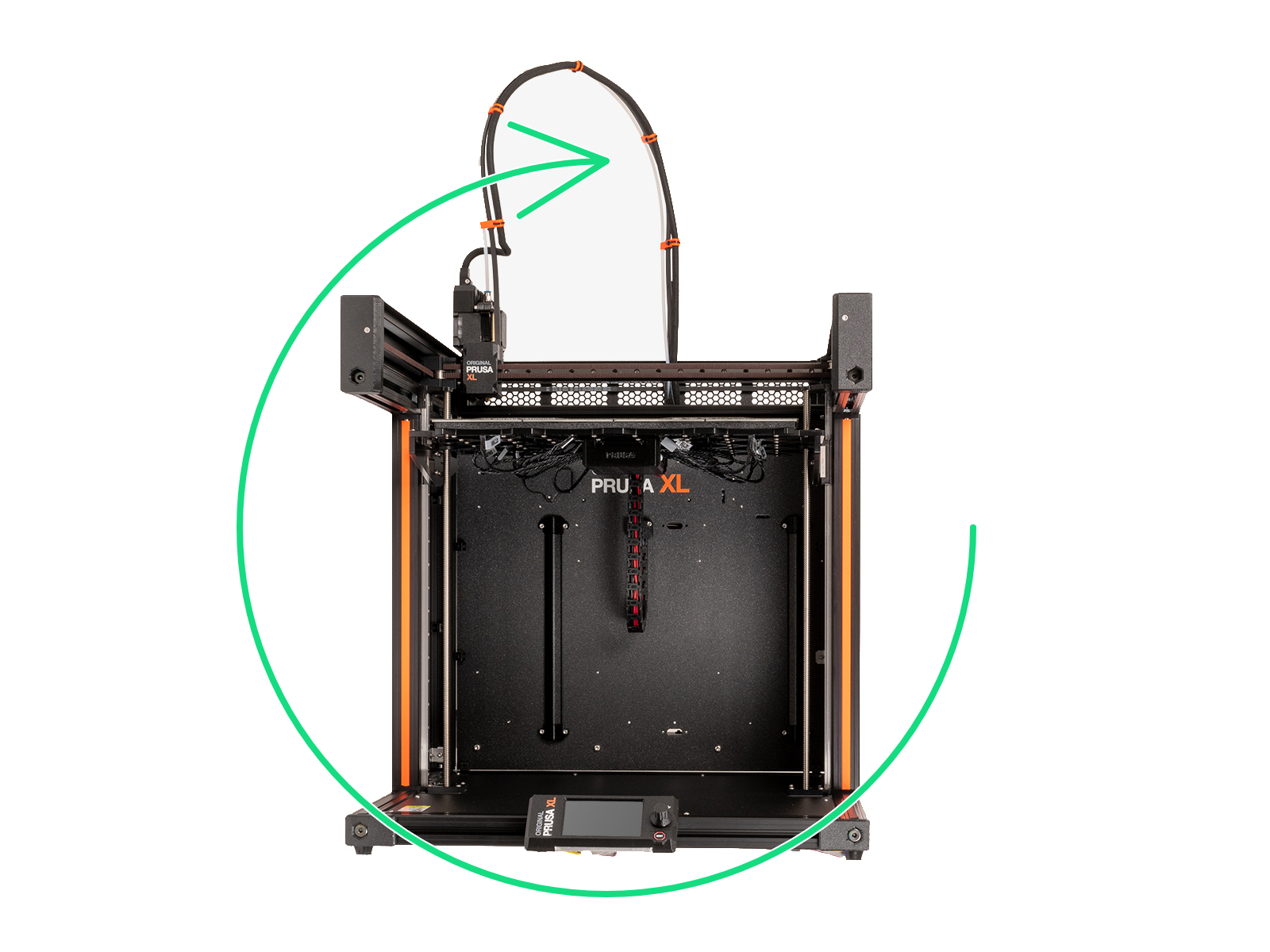

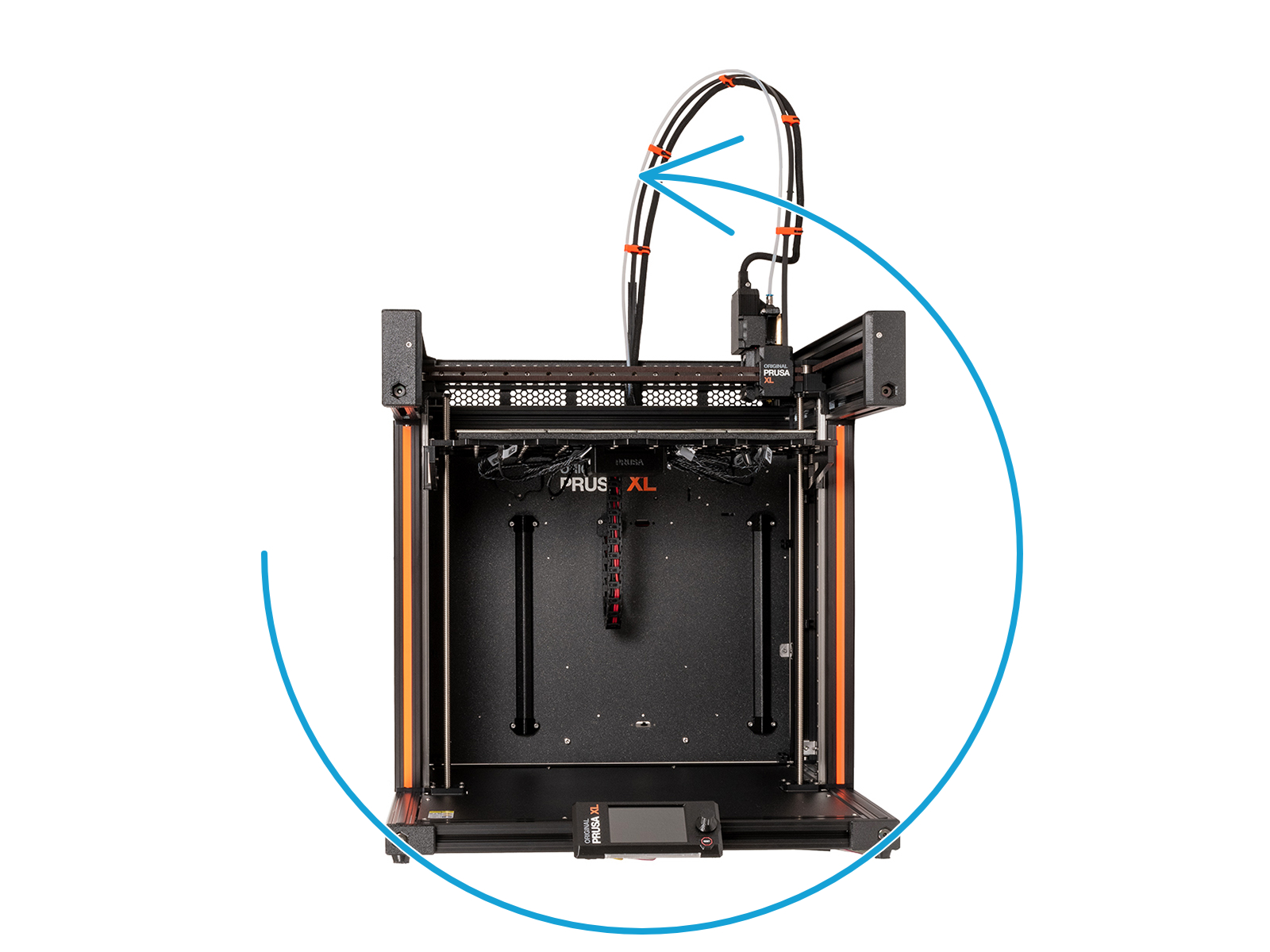

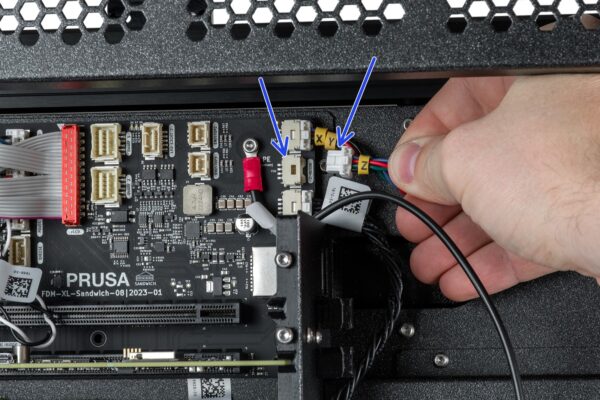

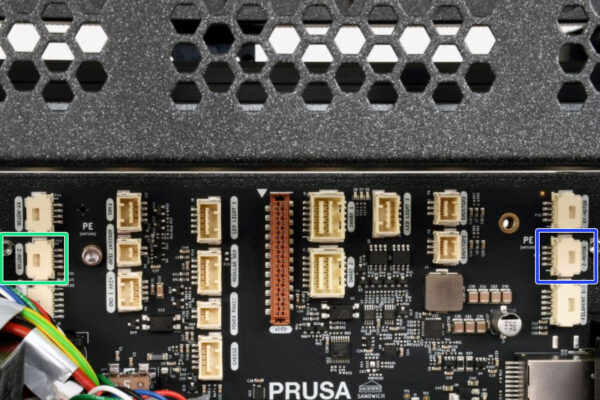

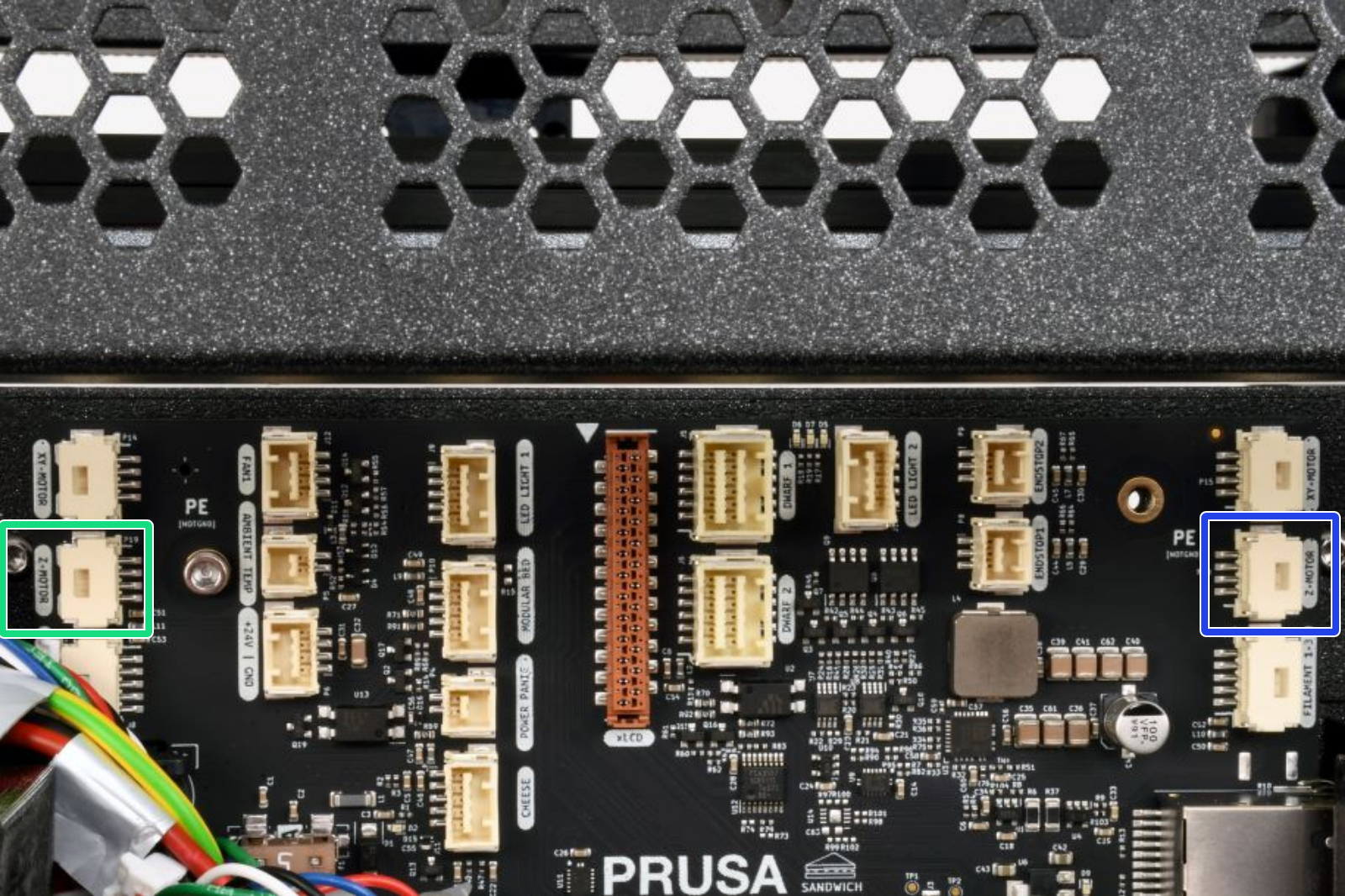

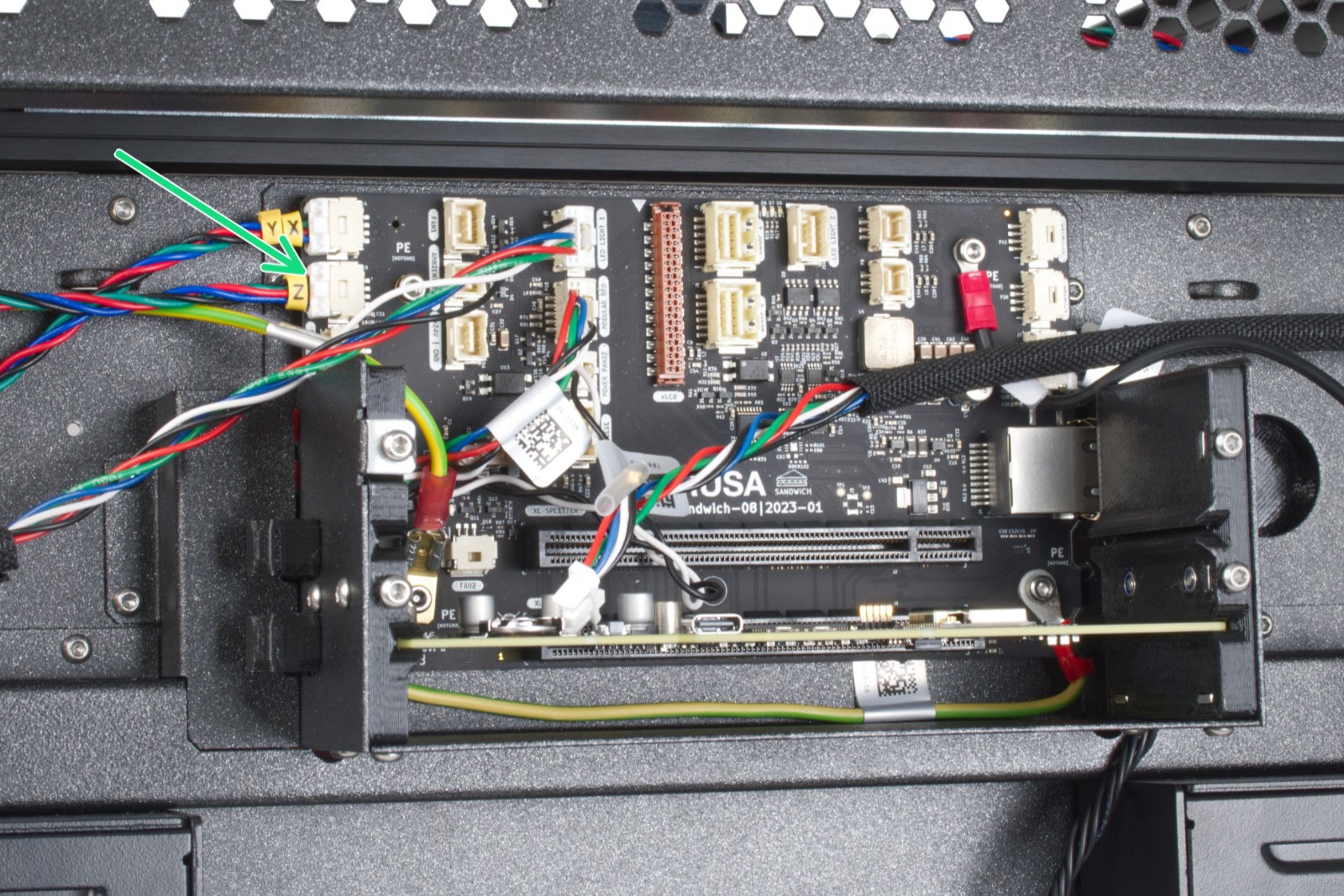

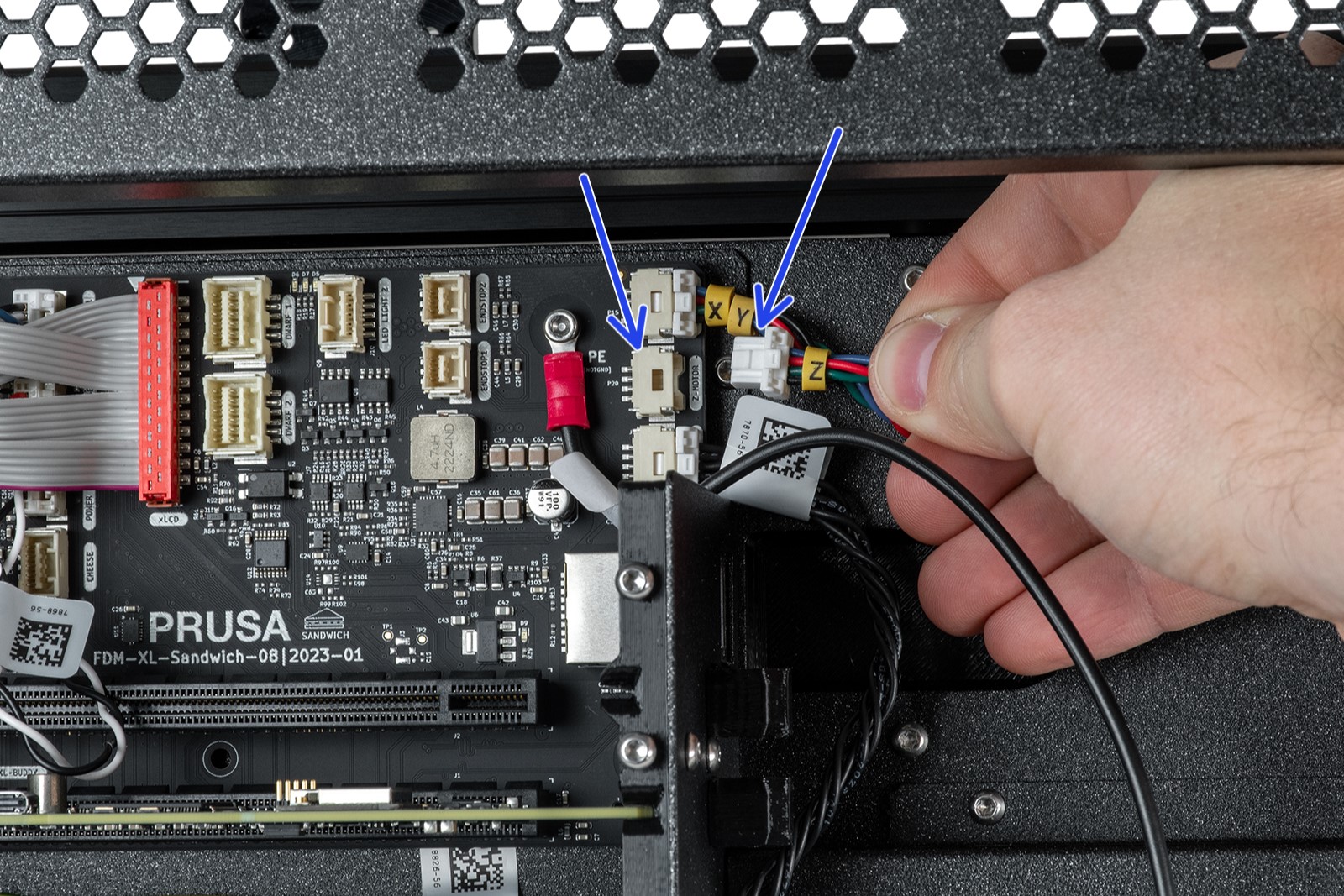

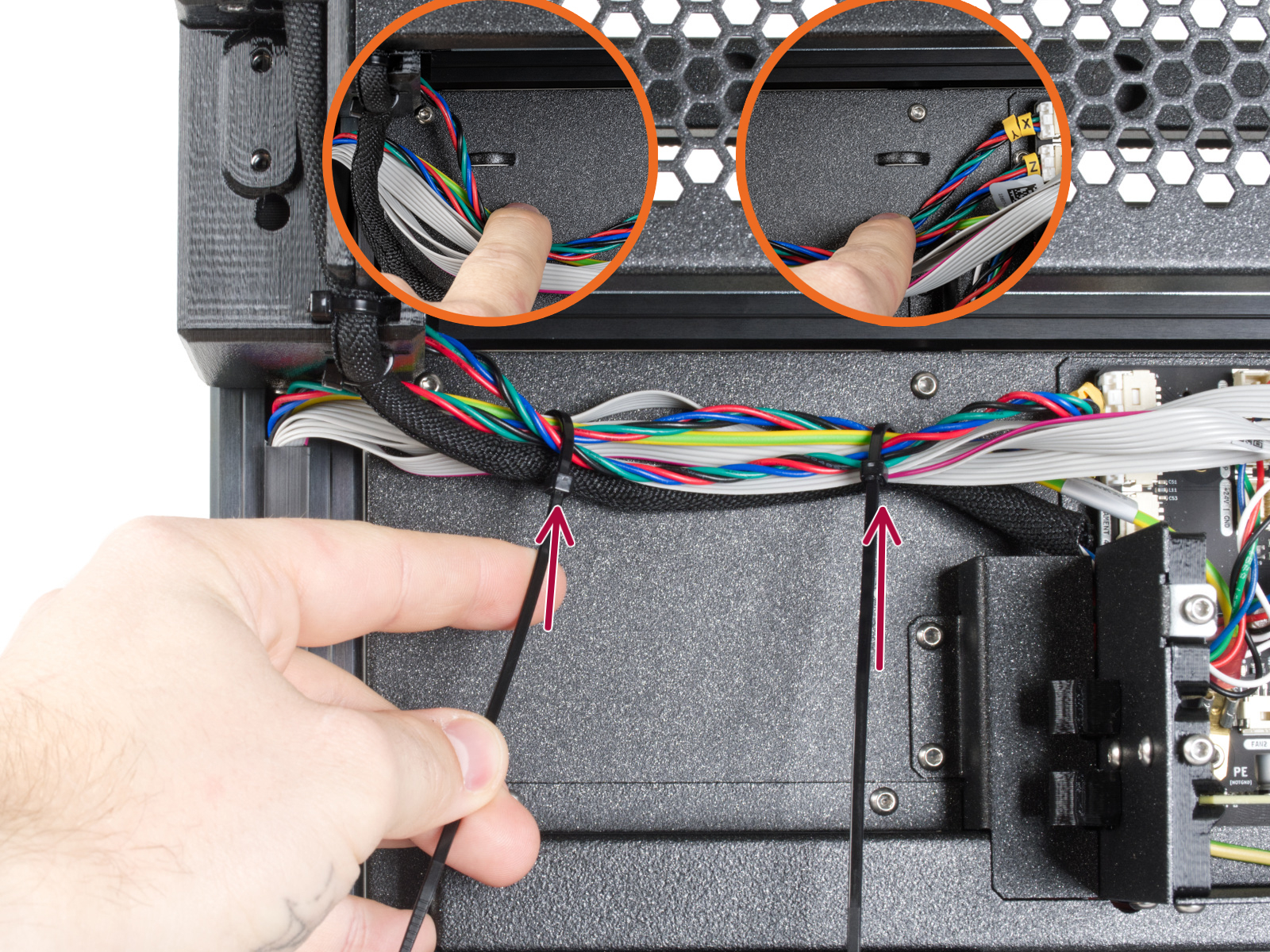

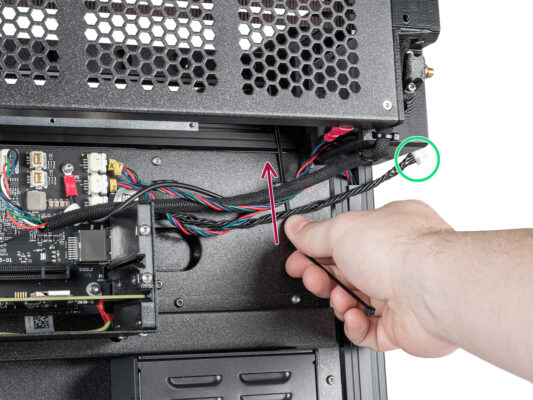

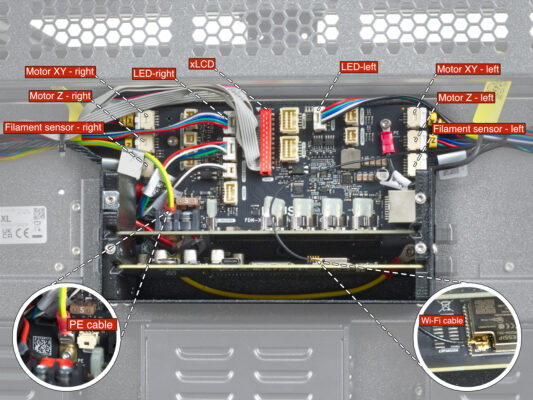

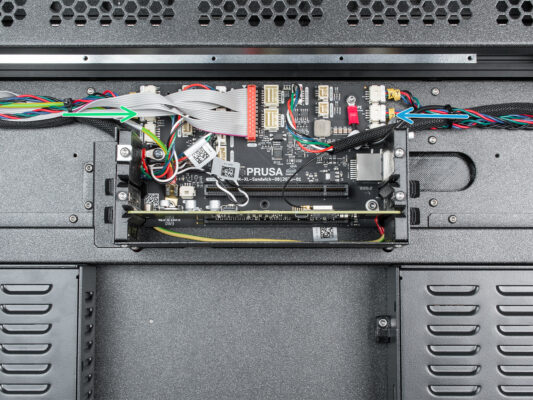

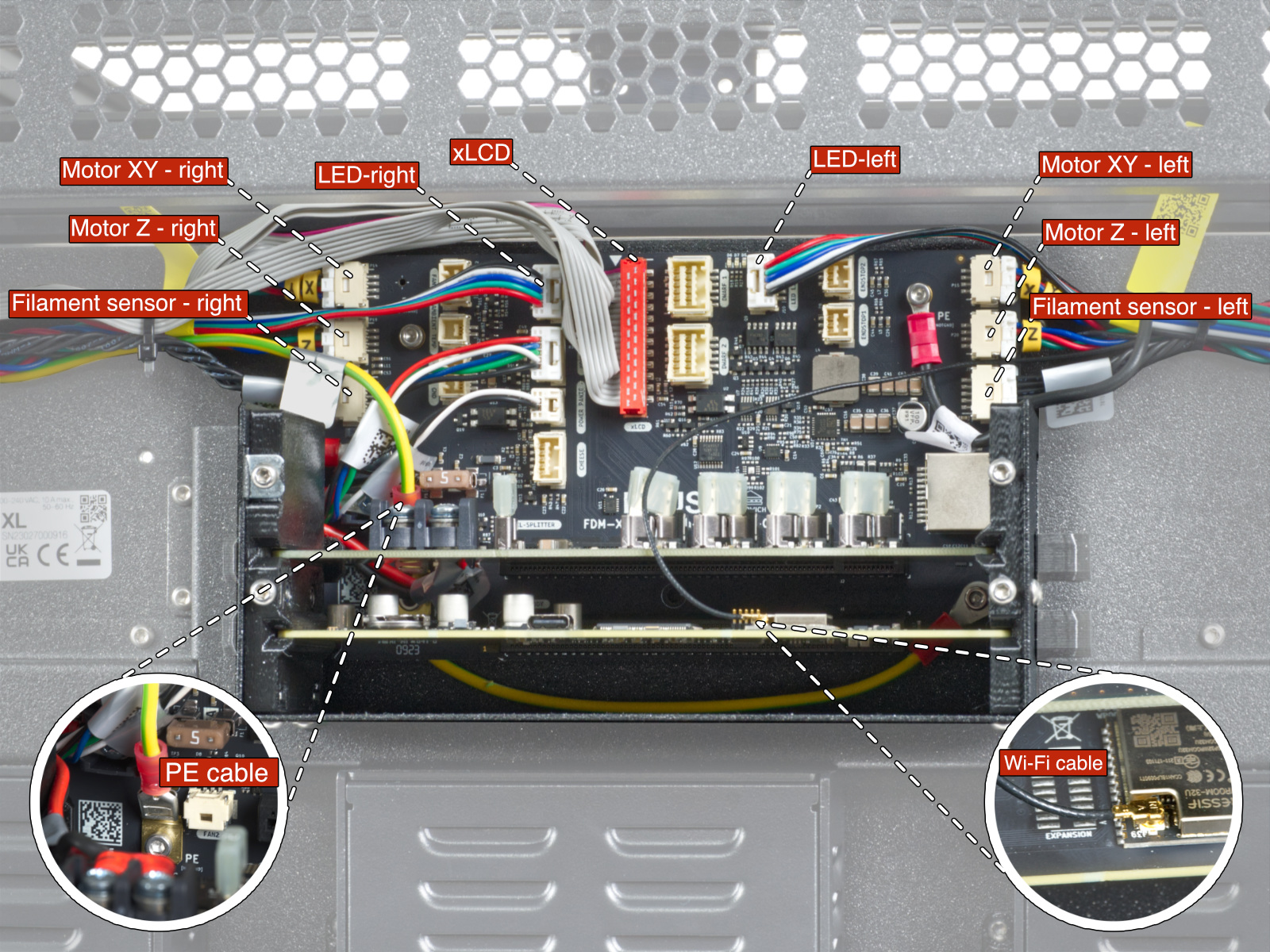

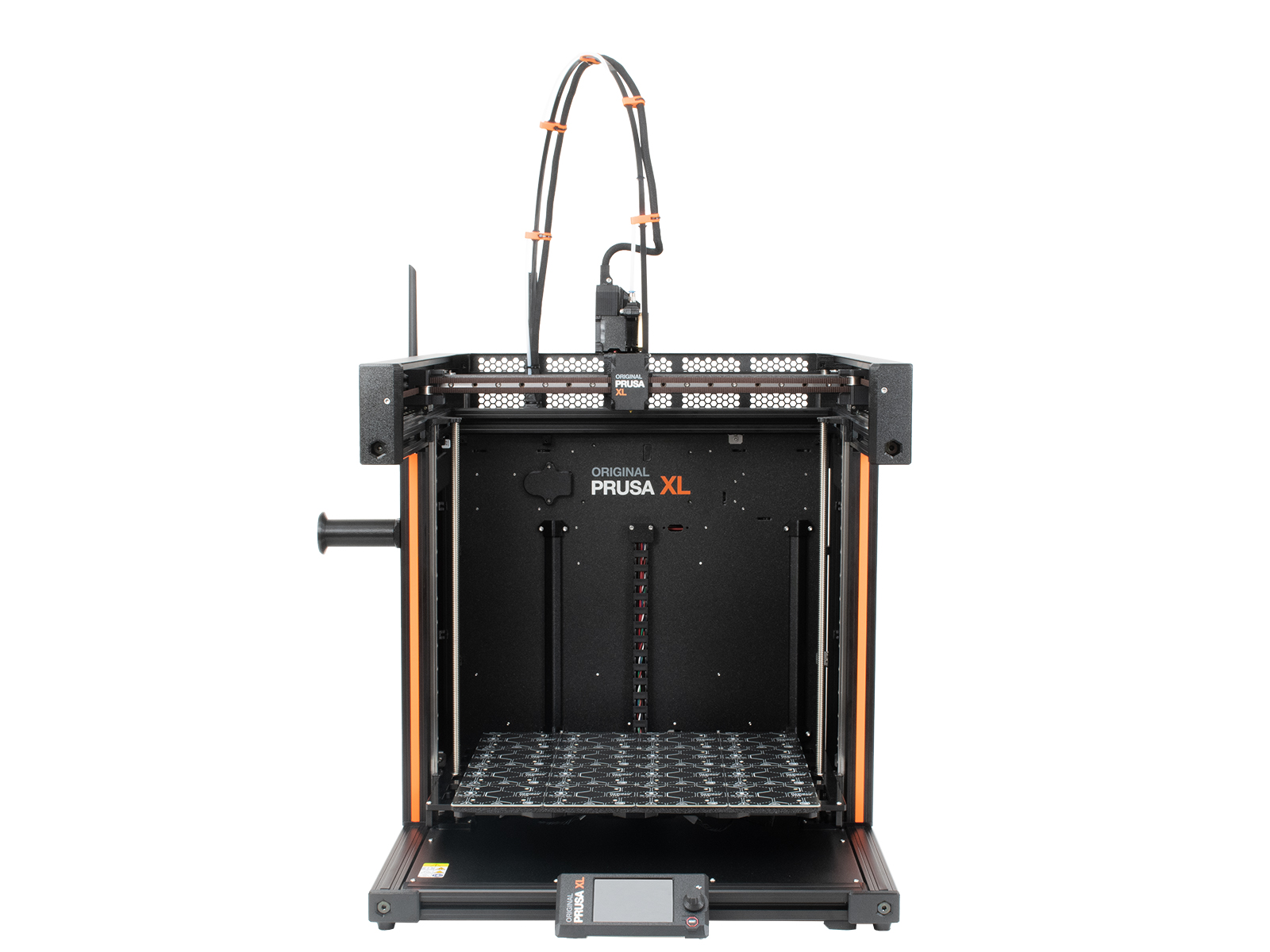

⬢This guide will take you through the replacement of the Z-axis motor on the Original Prusa XL.

The following instructions are compatible with all Original Prusa XL versions.

⬢All necessary parts are available in our eshop prusa3d.com.

Note that you have to be logged in to have access to the spare parts section.

This manual is for both Z-axis motors on the XL printer.