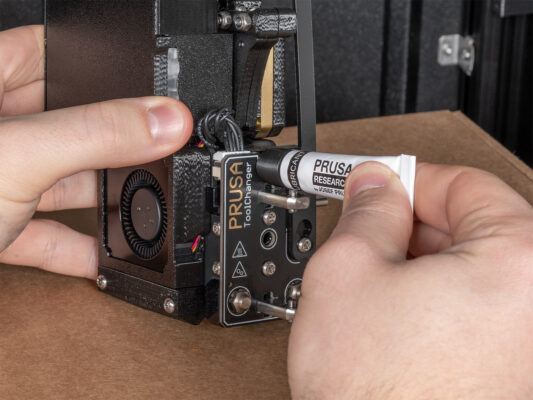

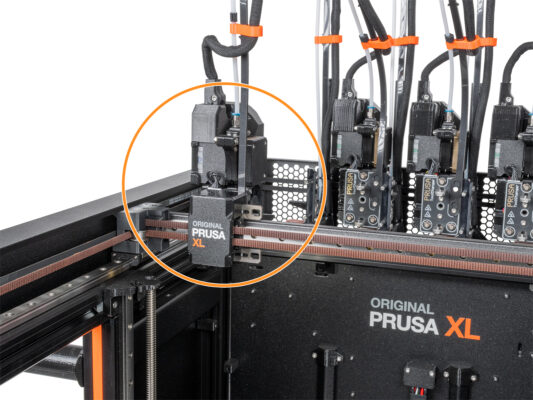

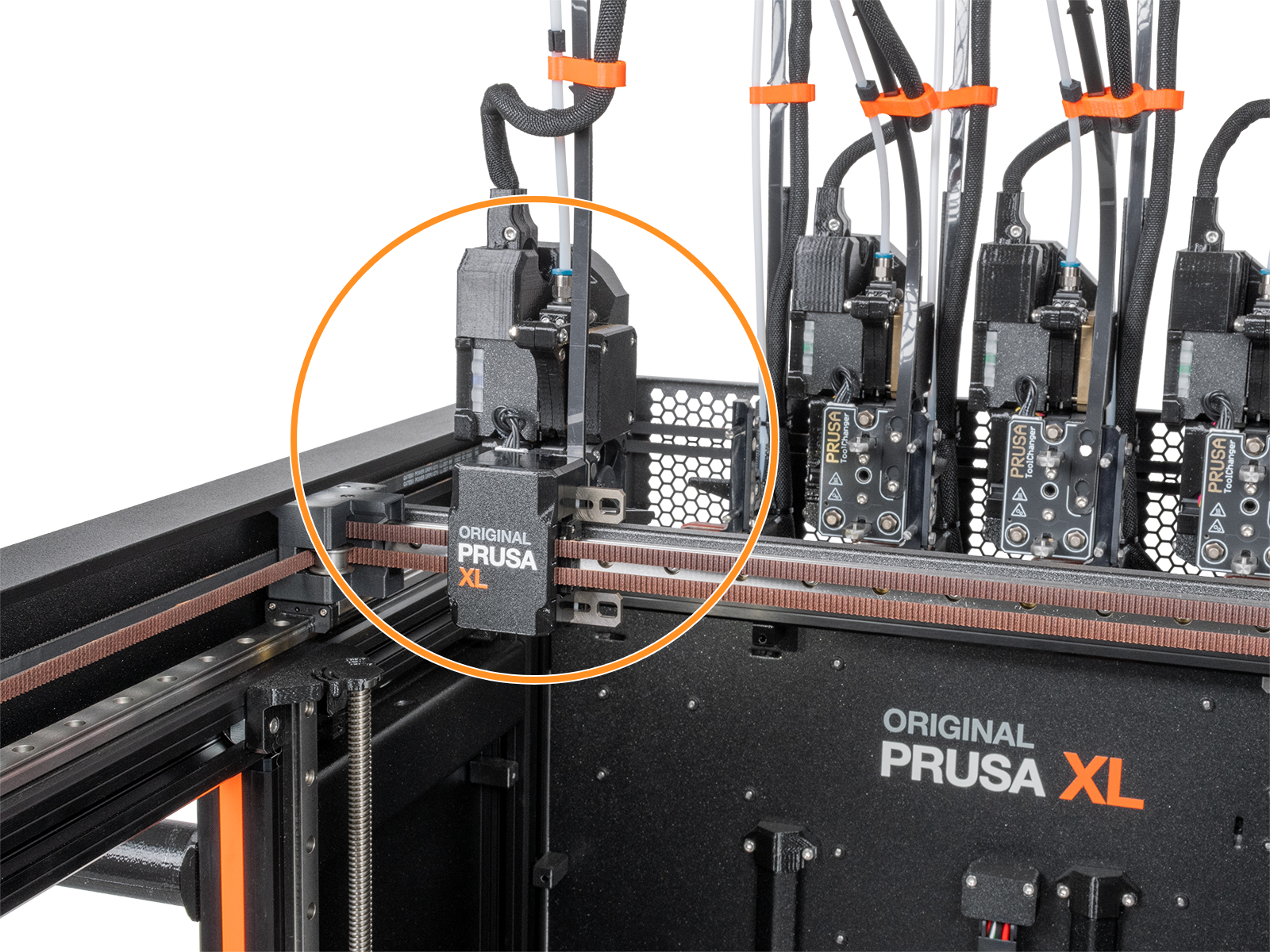

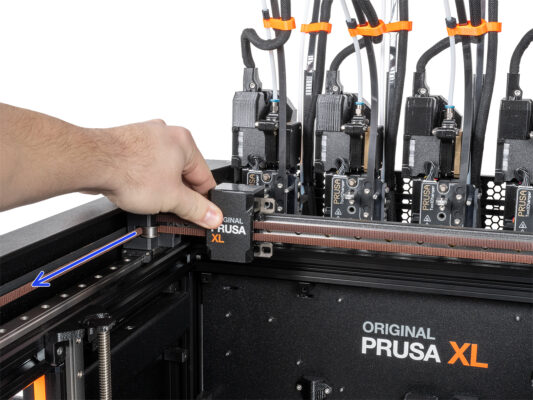

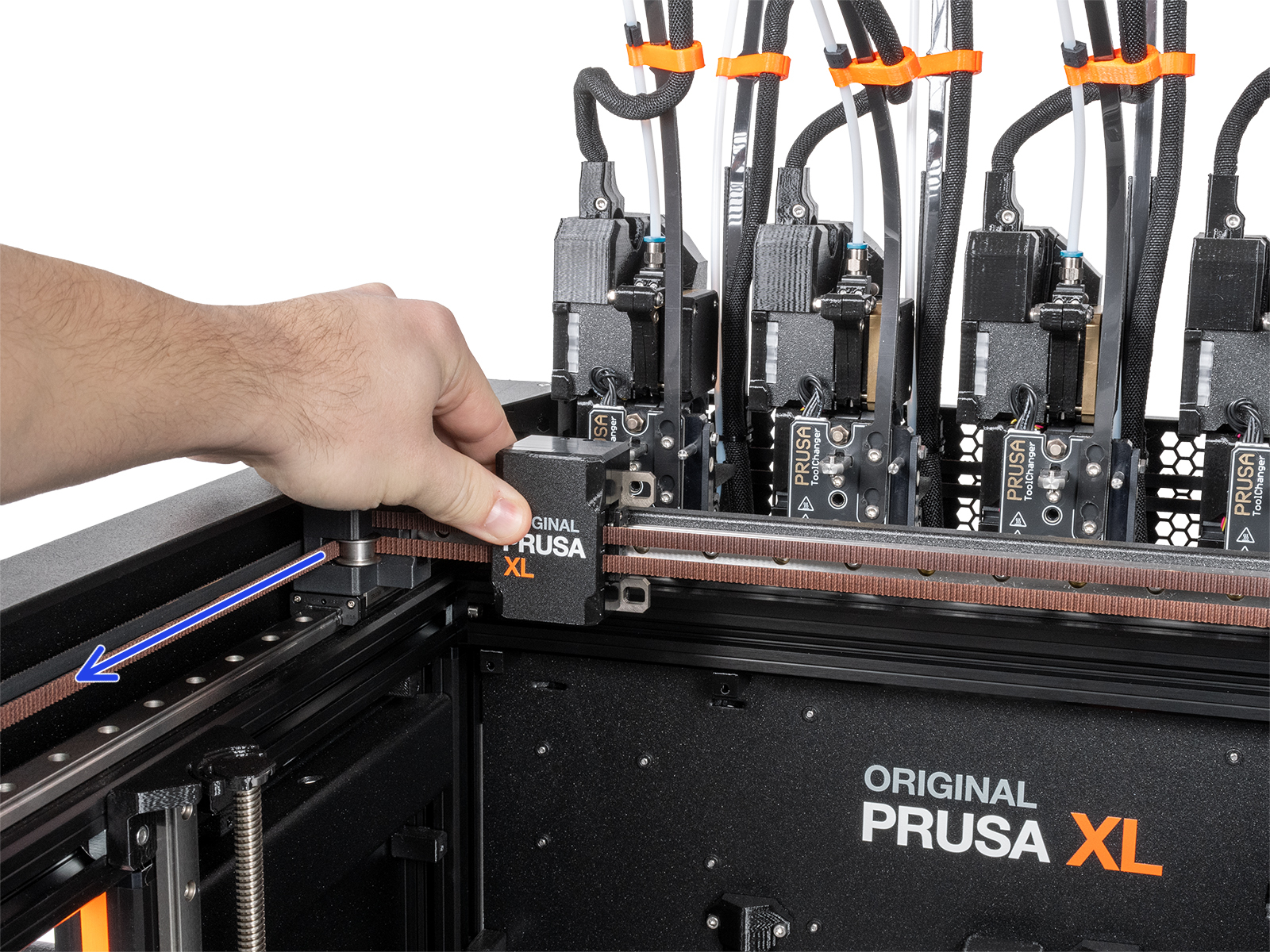

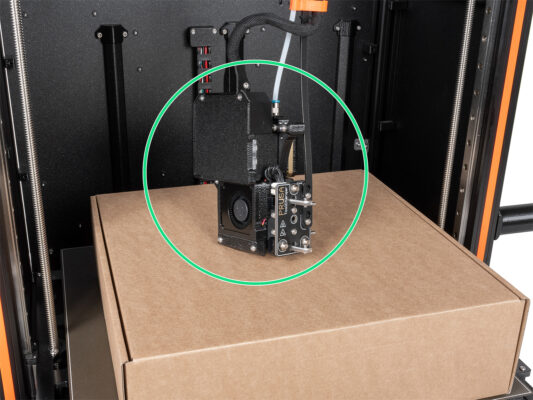

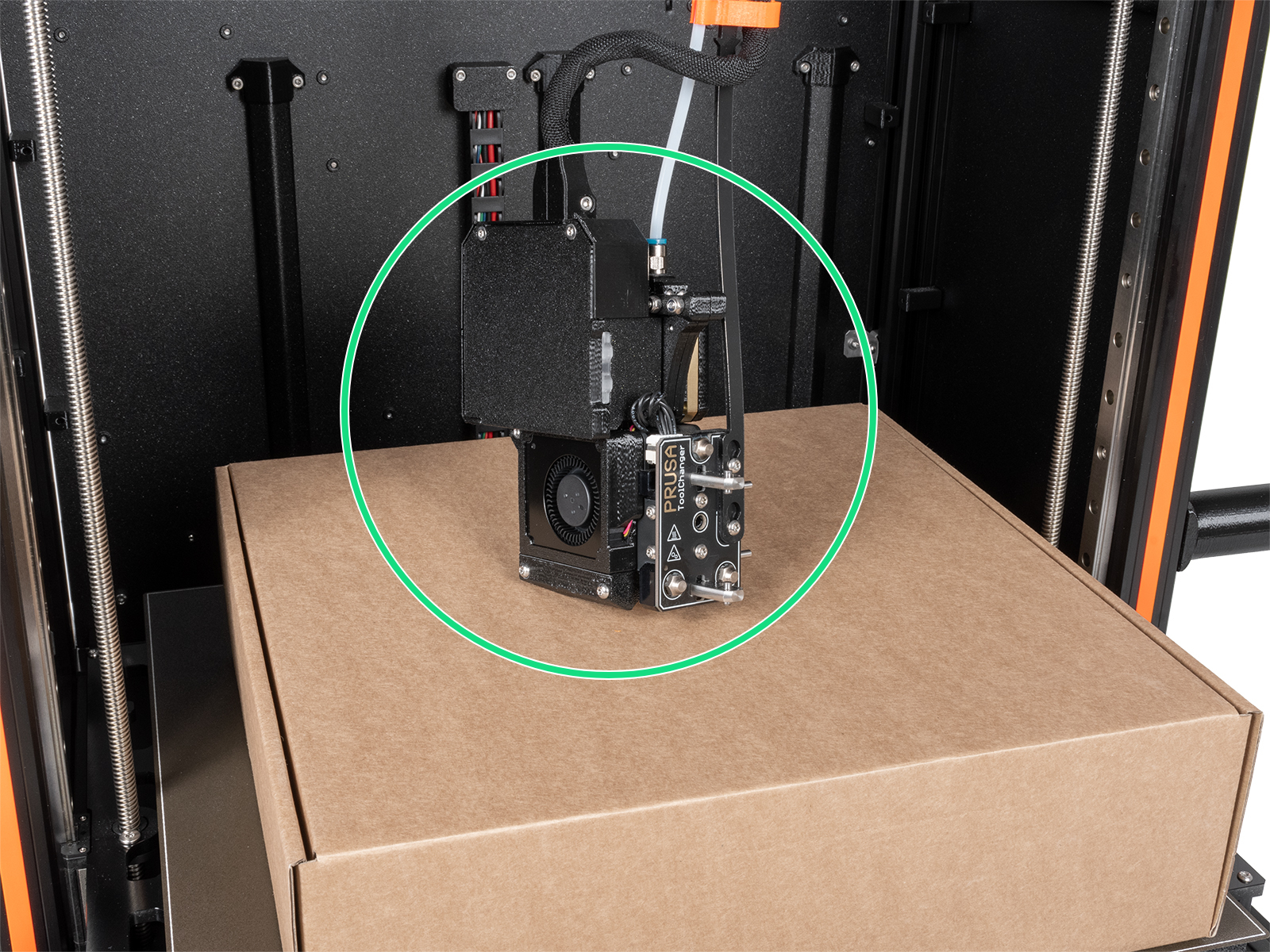

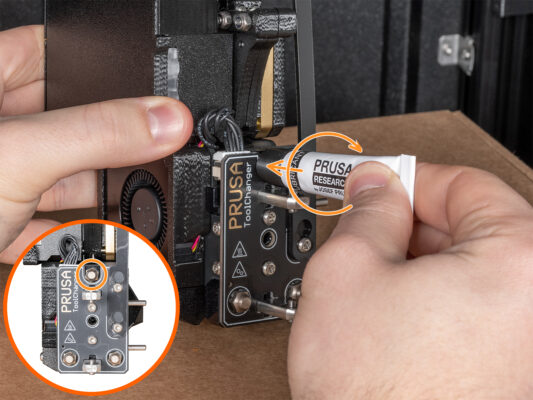

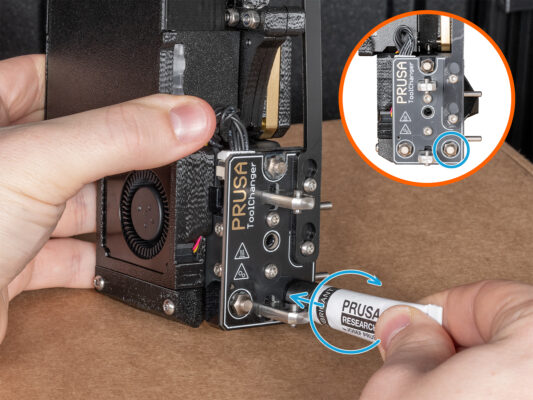

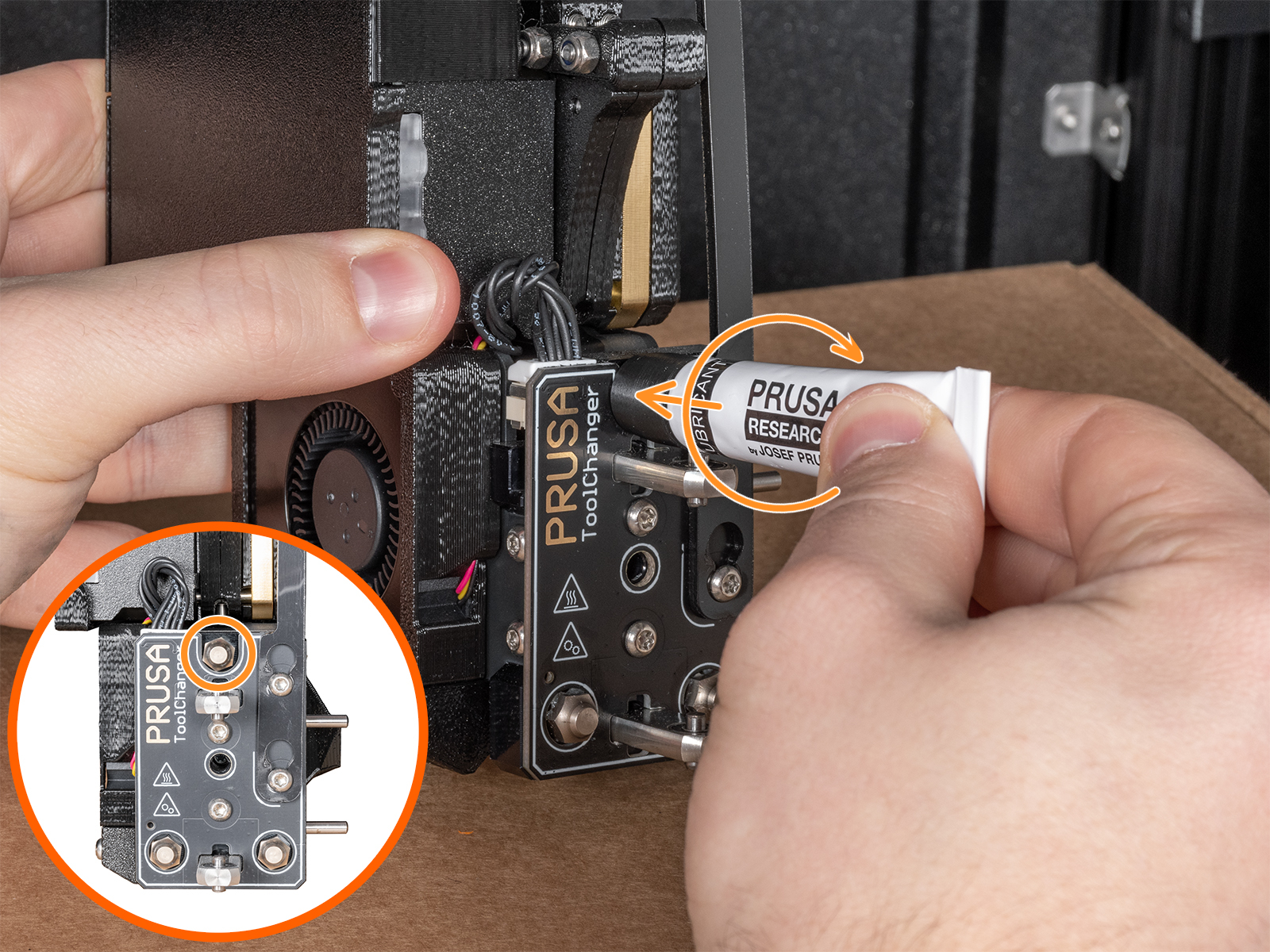

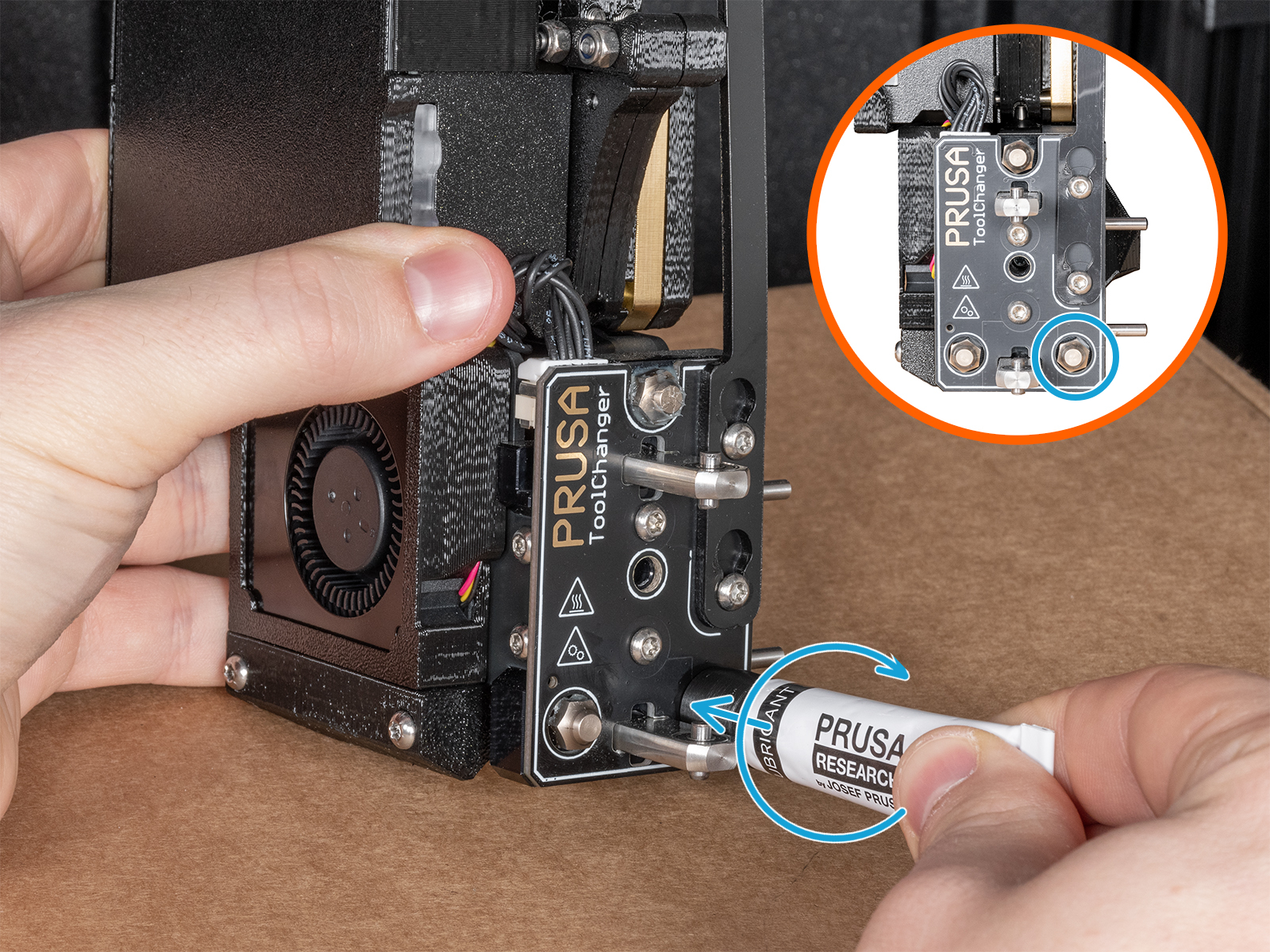

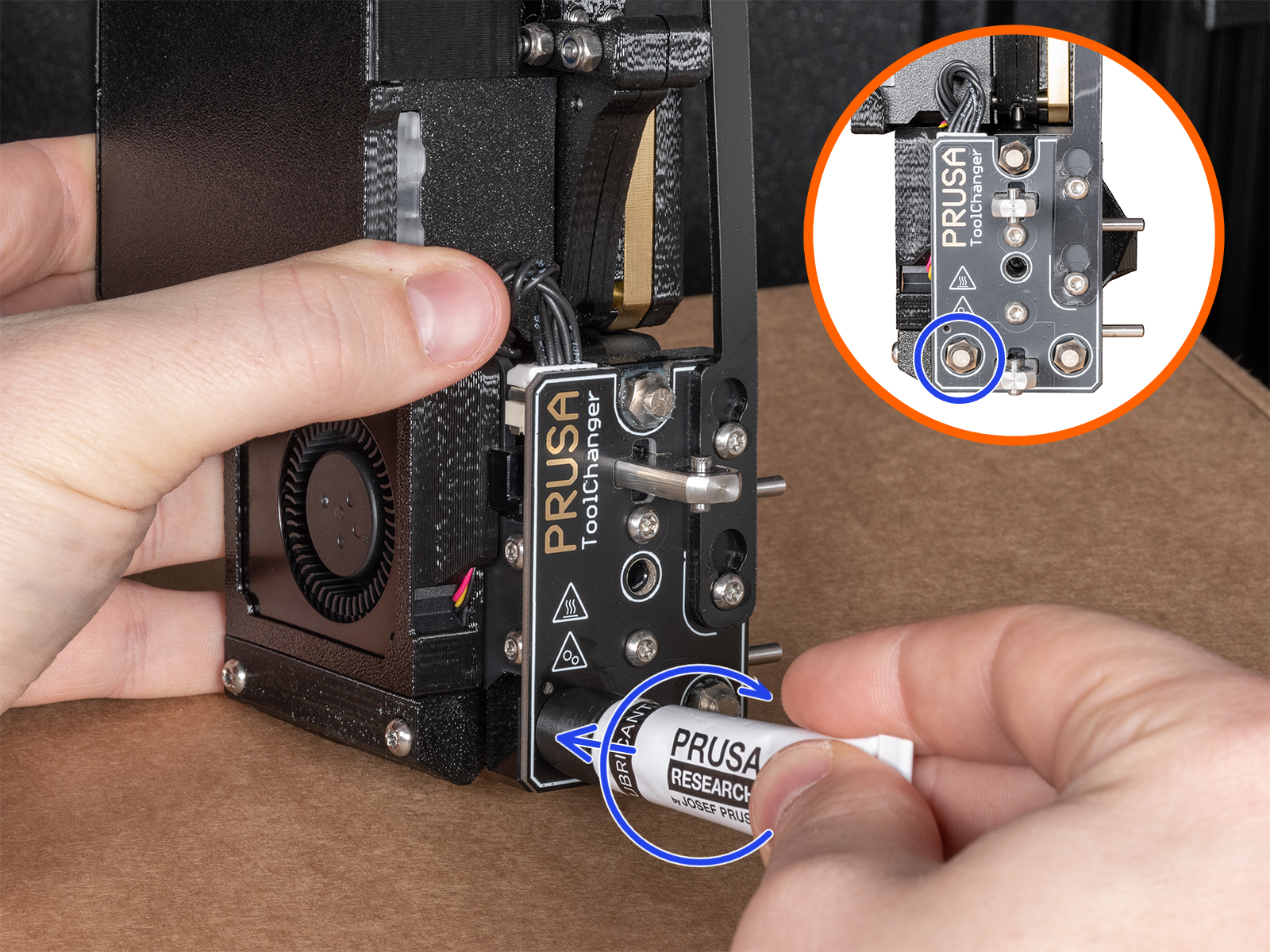

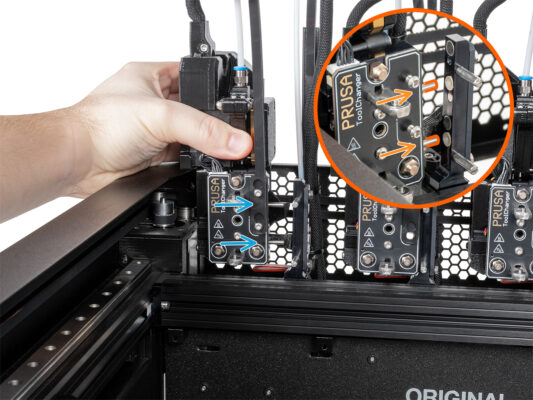

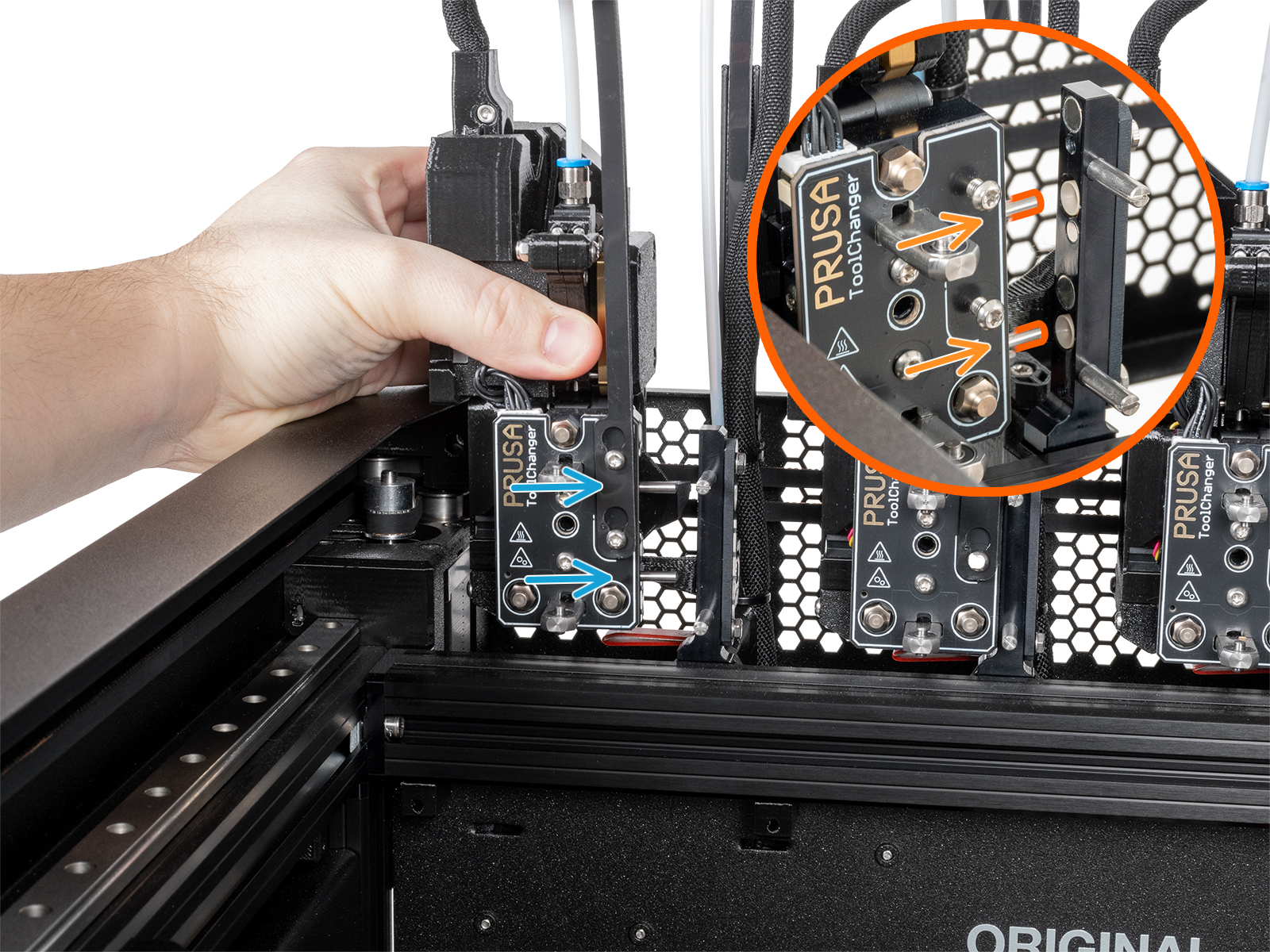

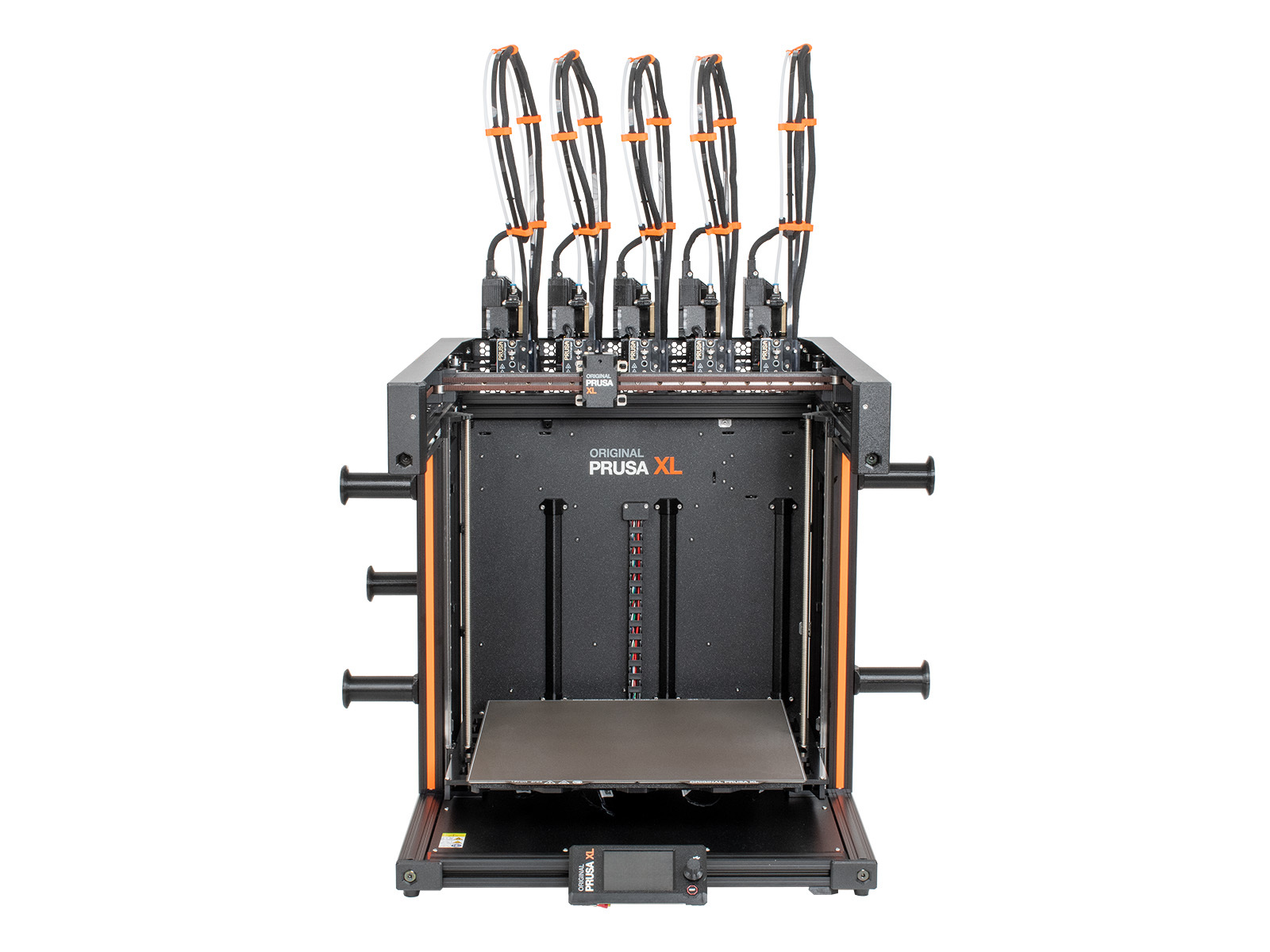

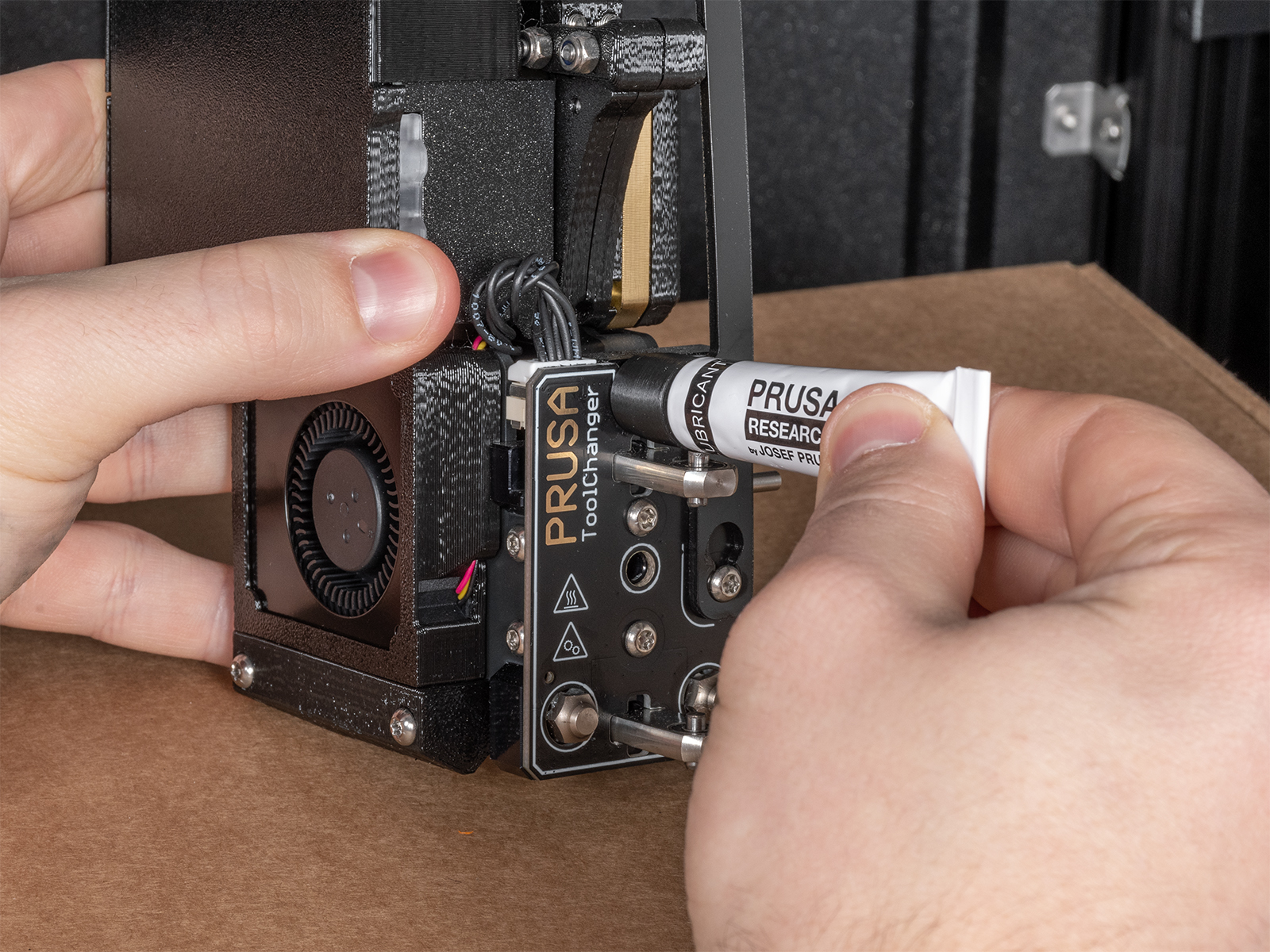

⬢This guide will take you through the lubricating of the Tool-changer on the Original Prusa XL (Multi-tool).

The following instructions are intended for XL Multi-Tool only.

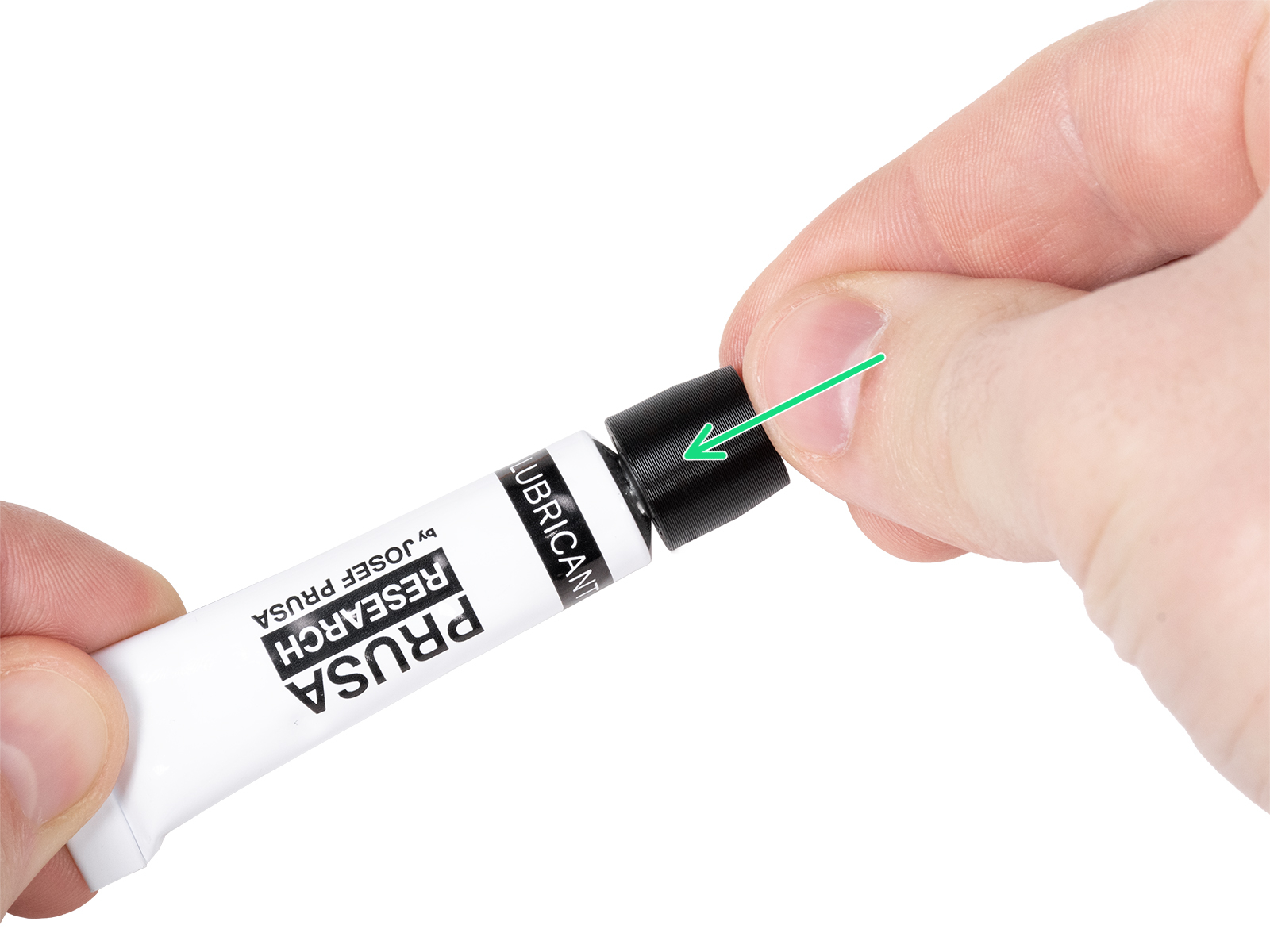

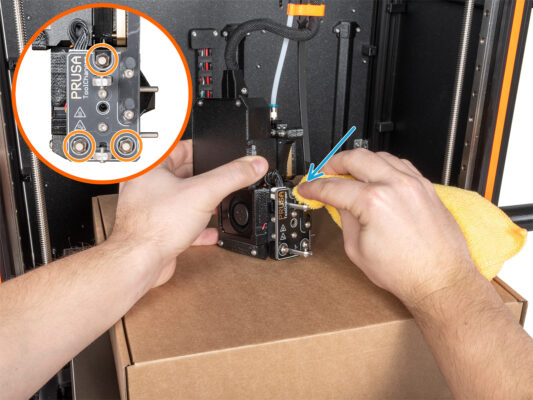

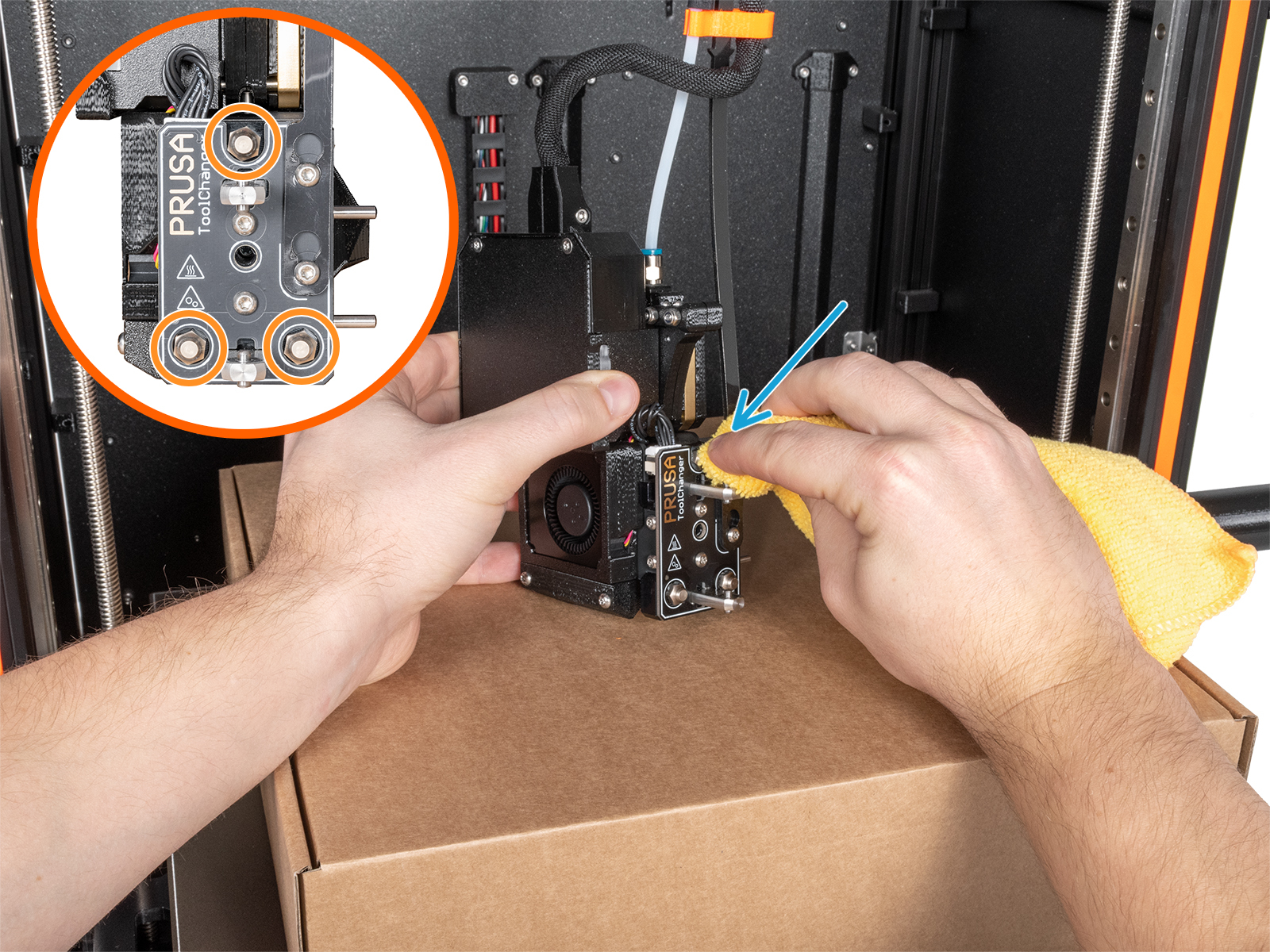

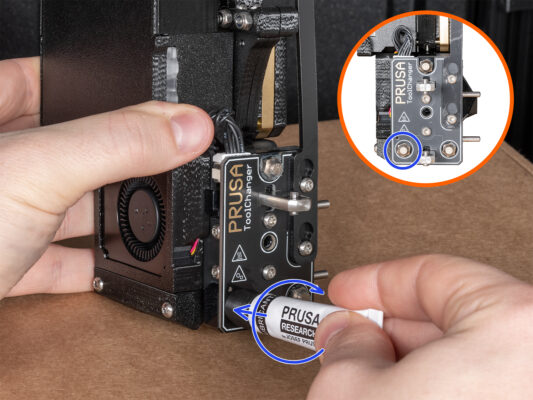

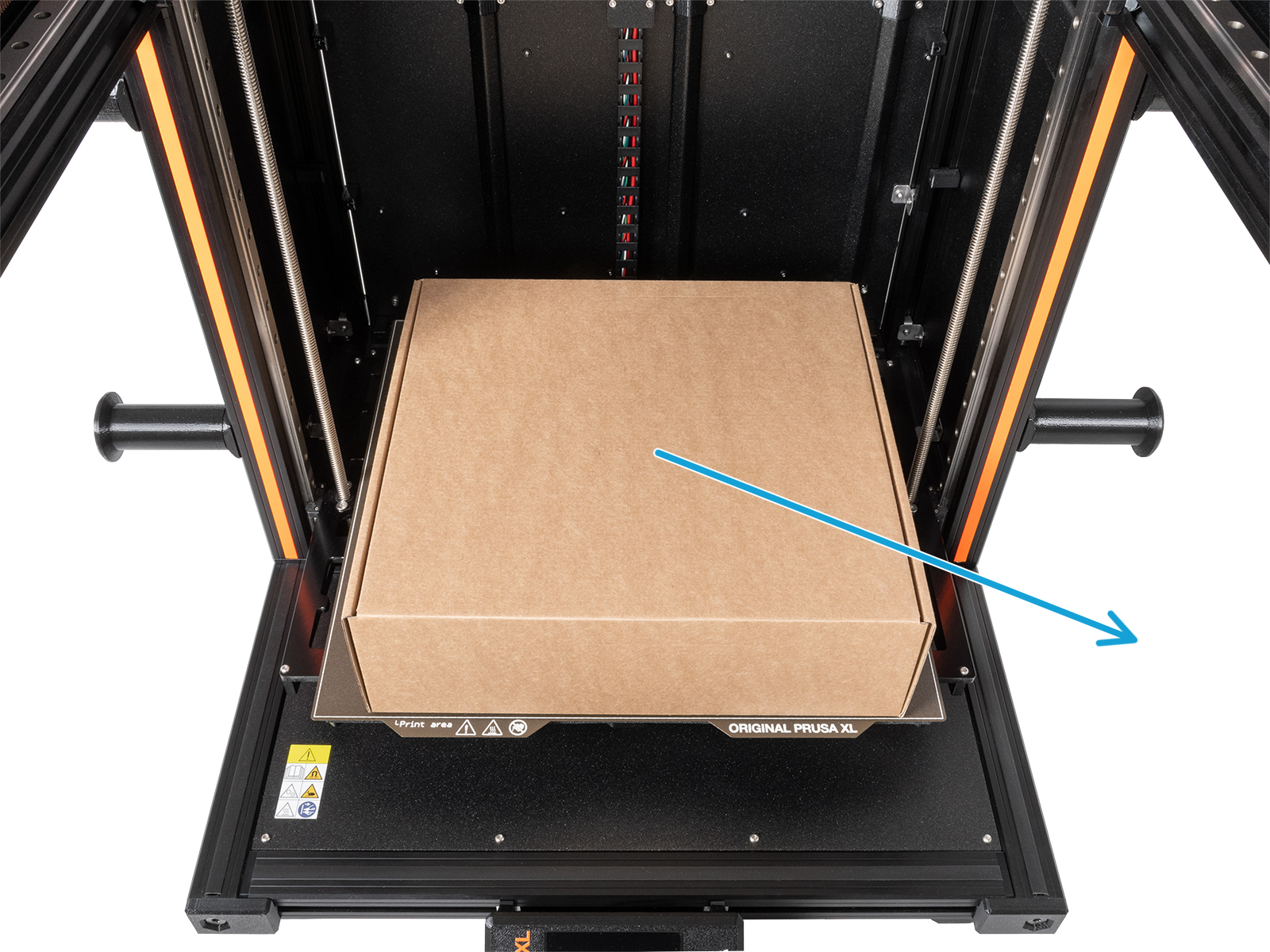

Before you start with the printer surgery, download and print the required lubricant applicator tc_greaser from Printables.com.