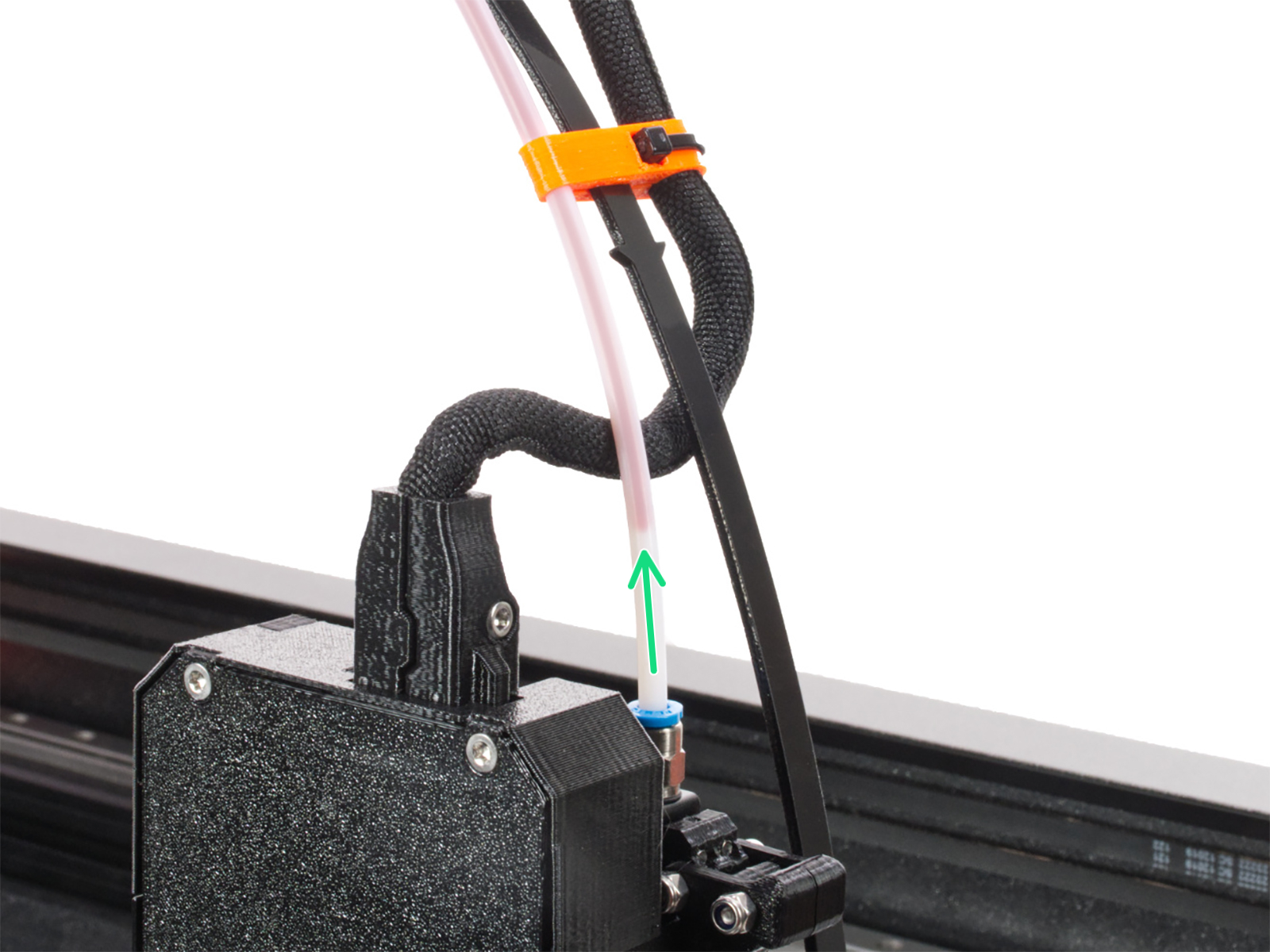

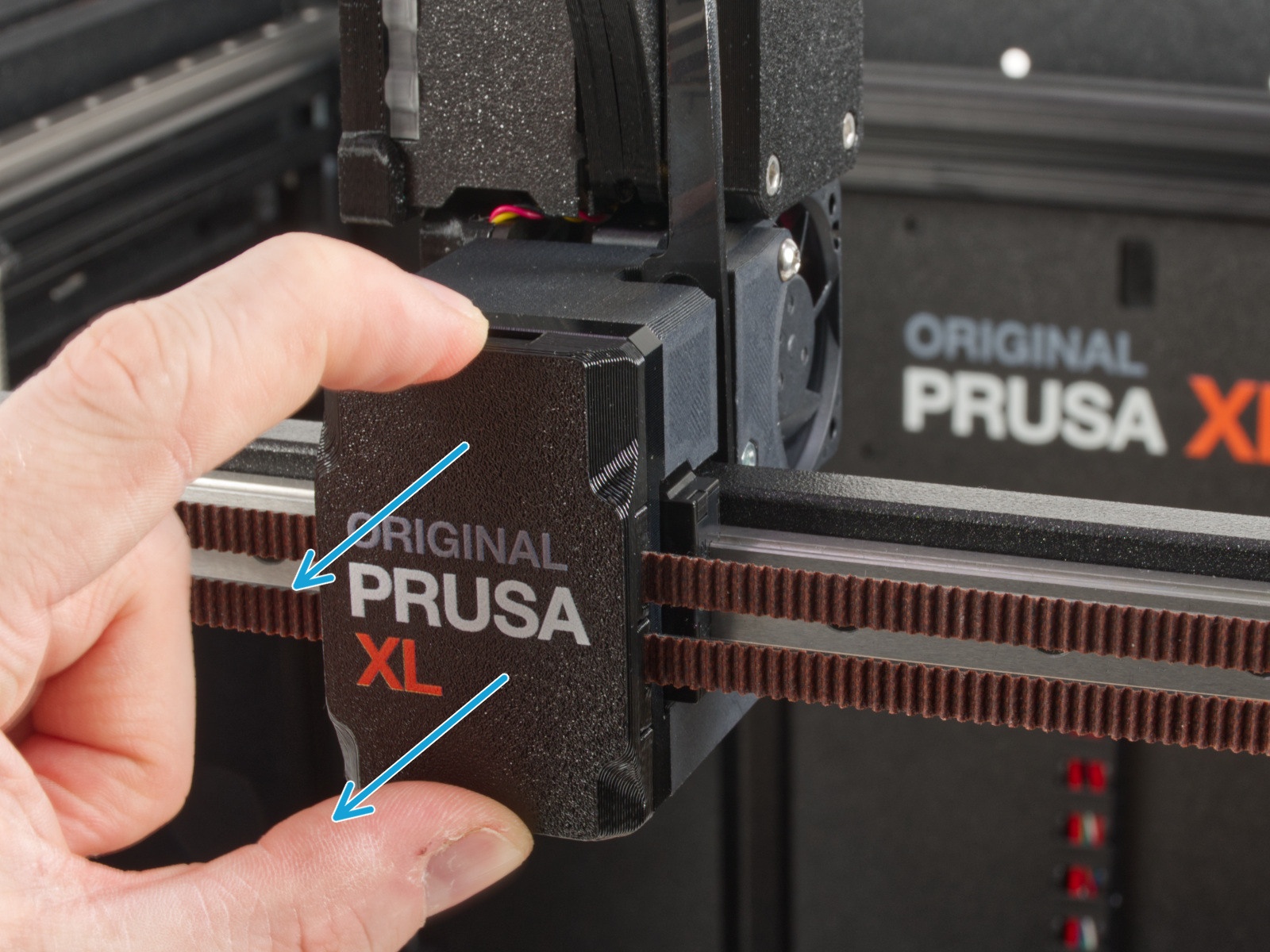

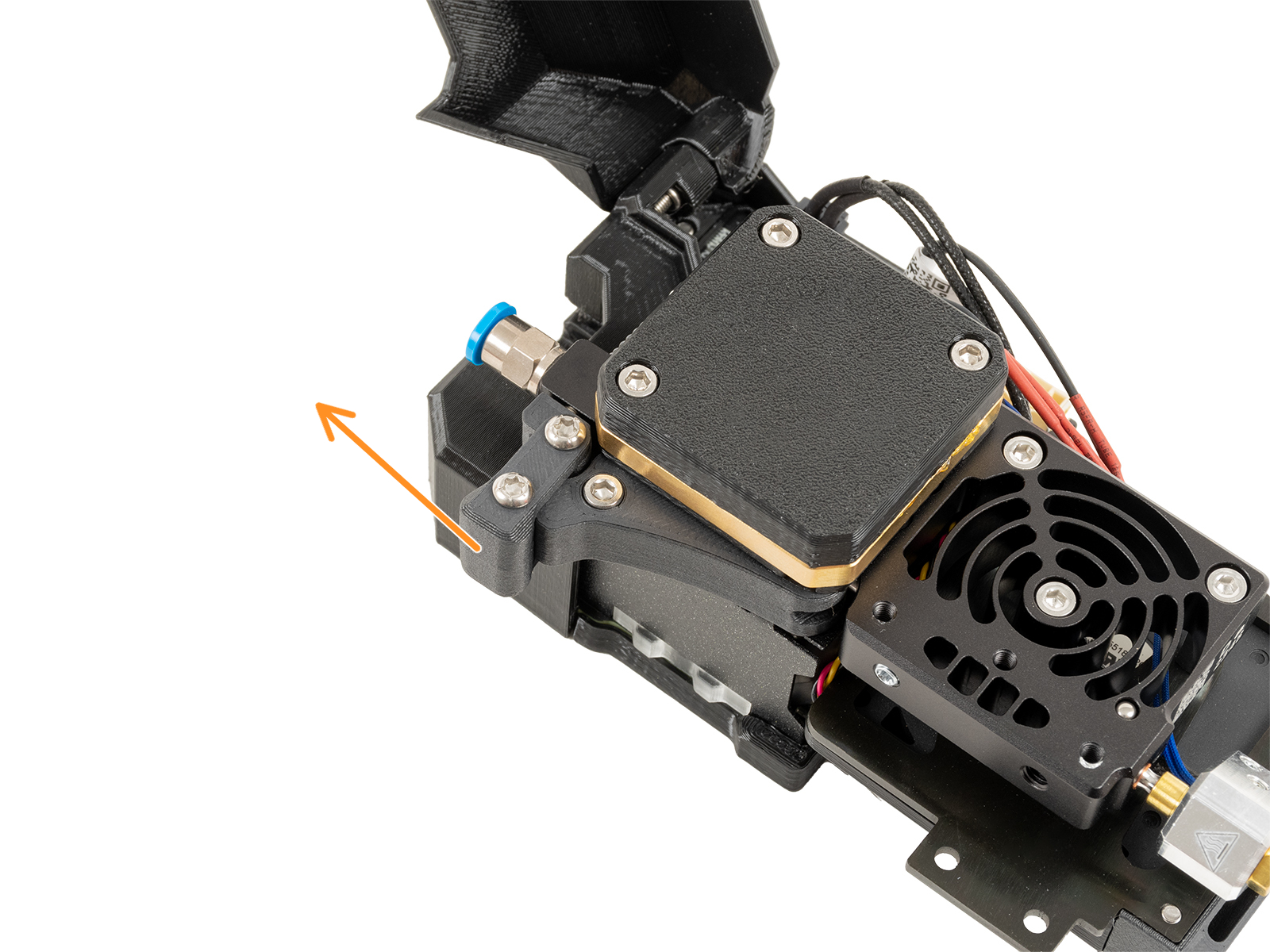

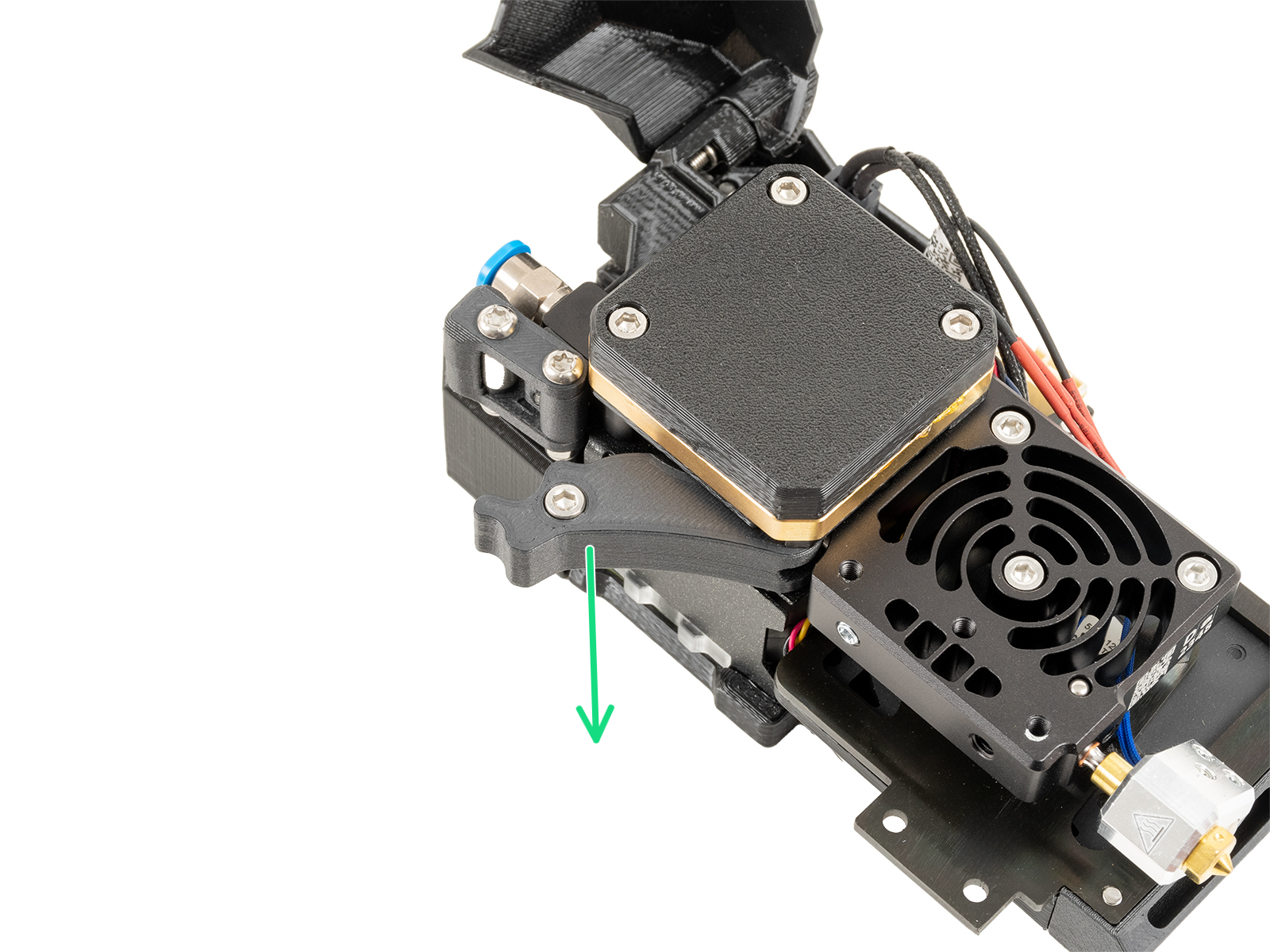

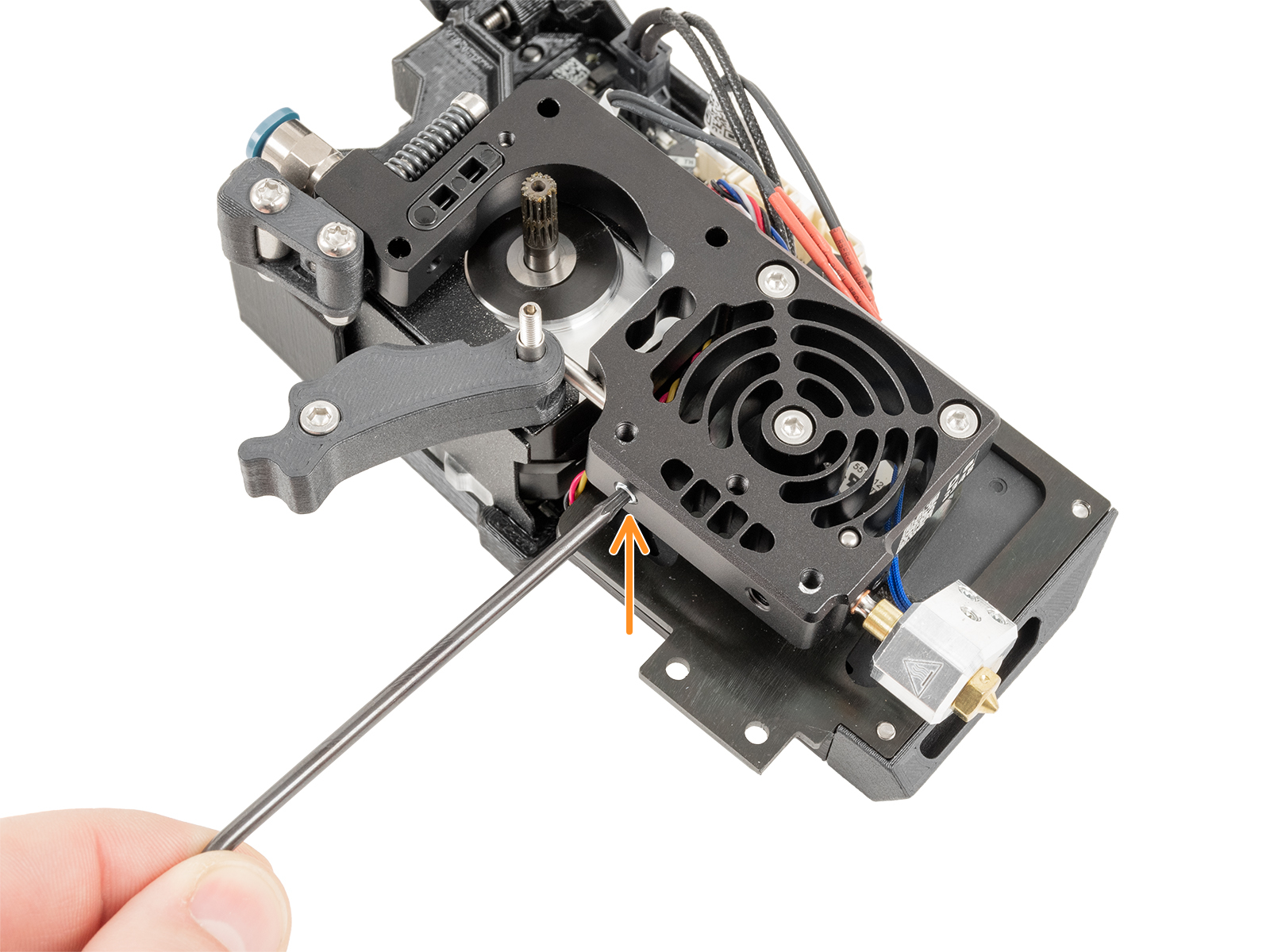

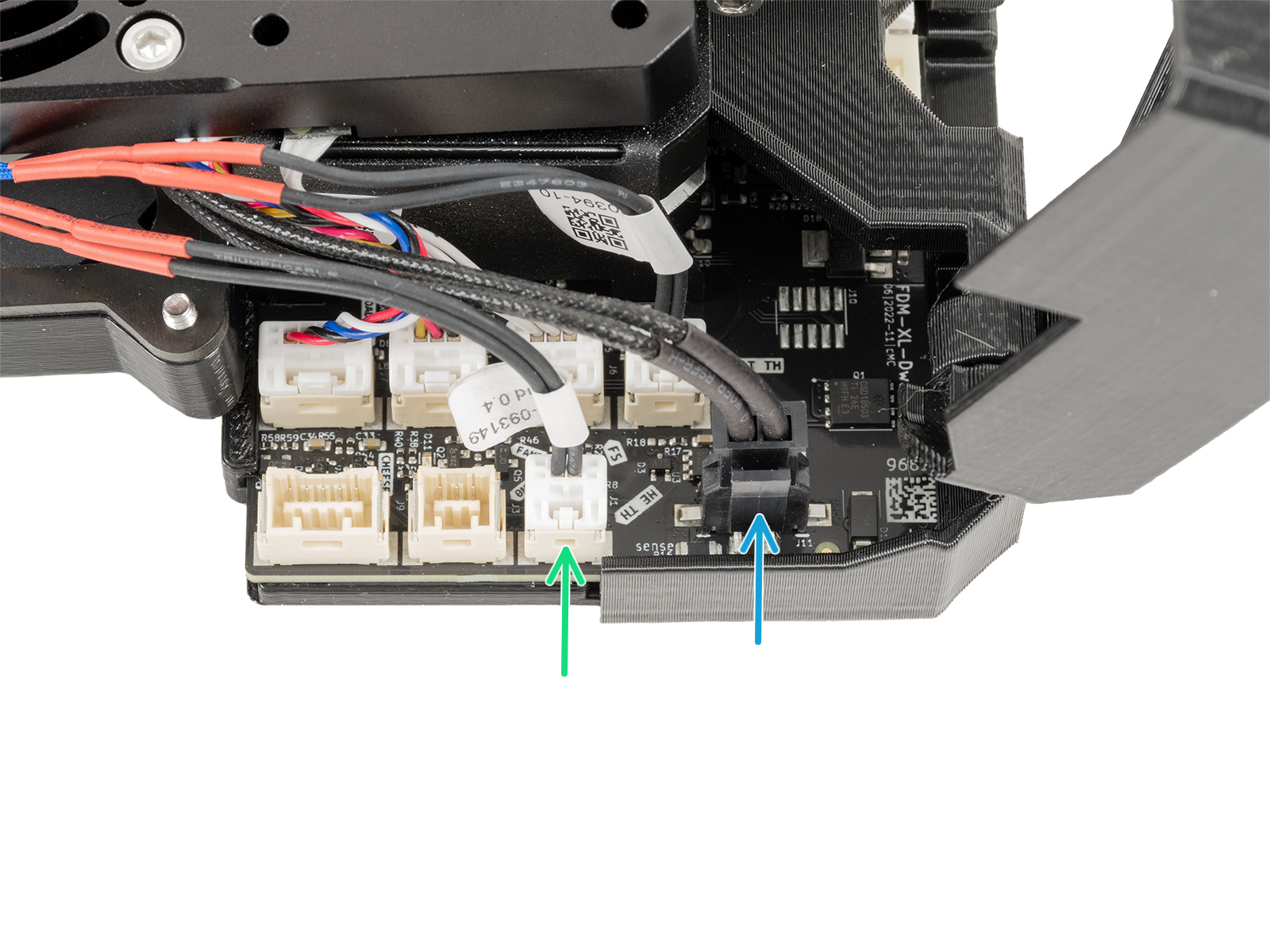

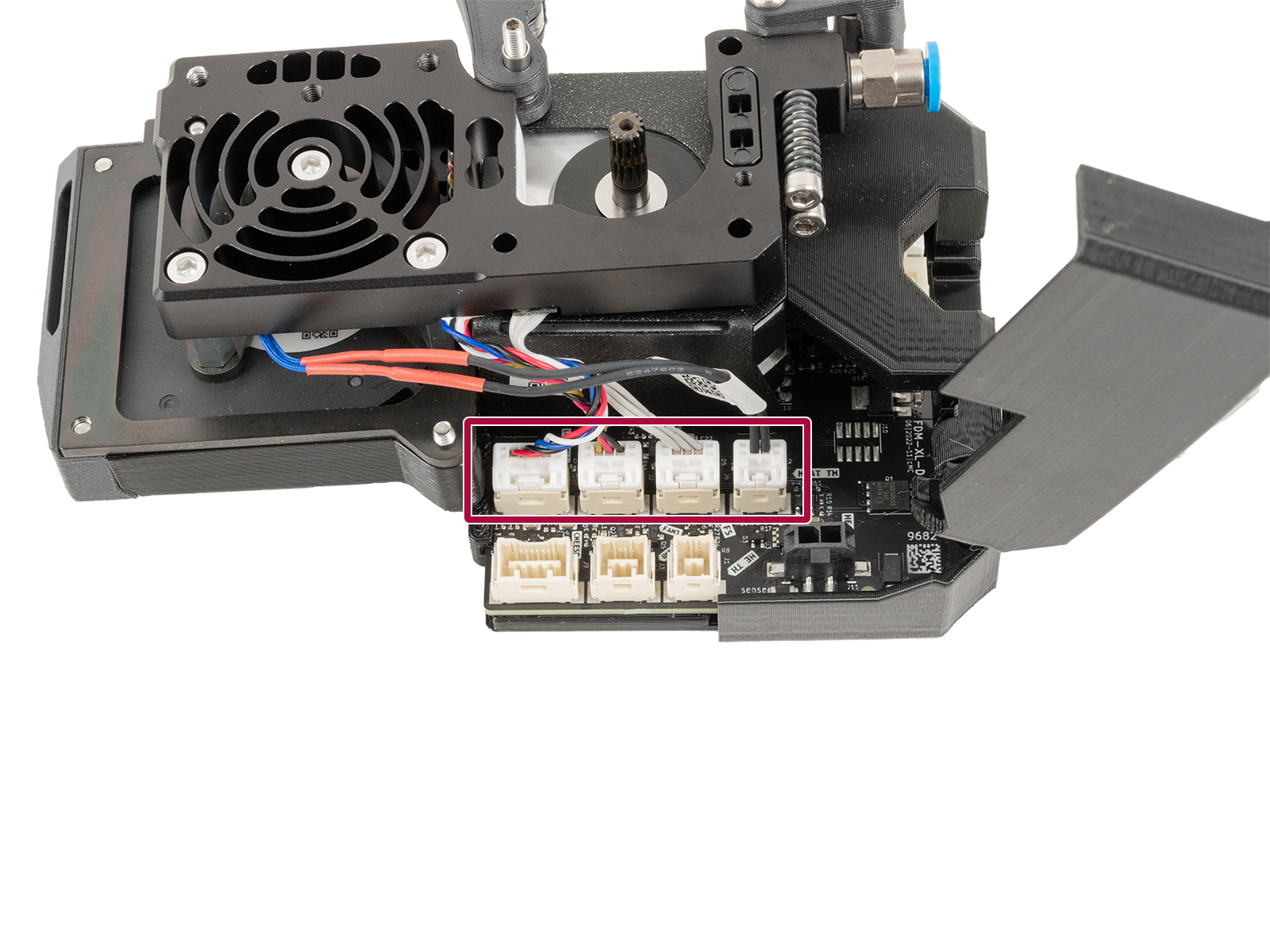

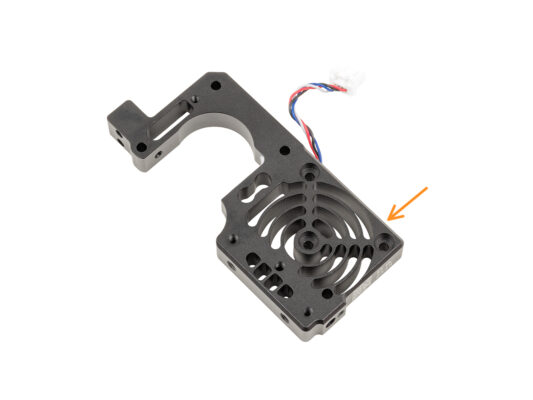

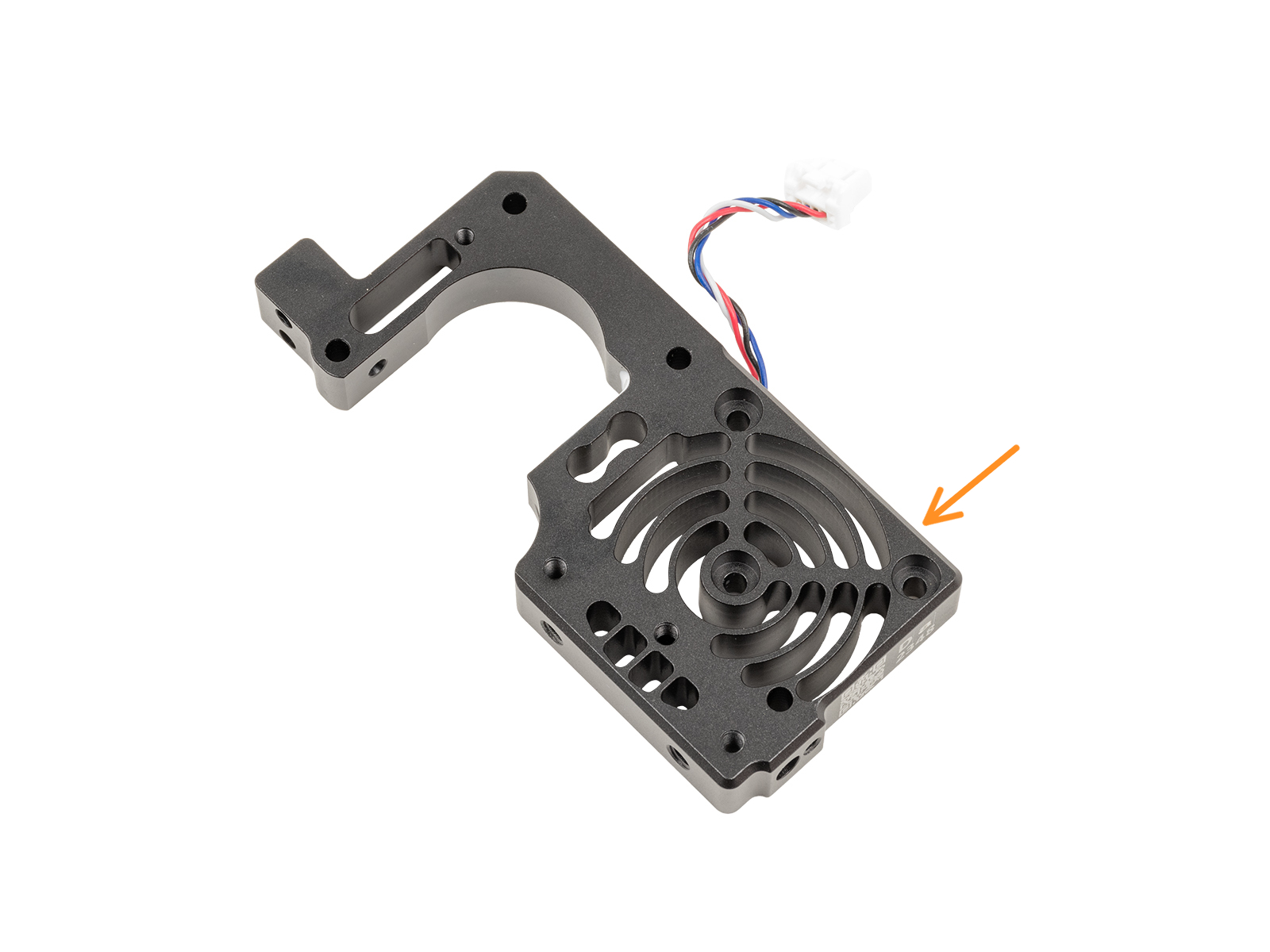

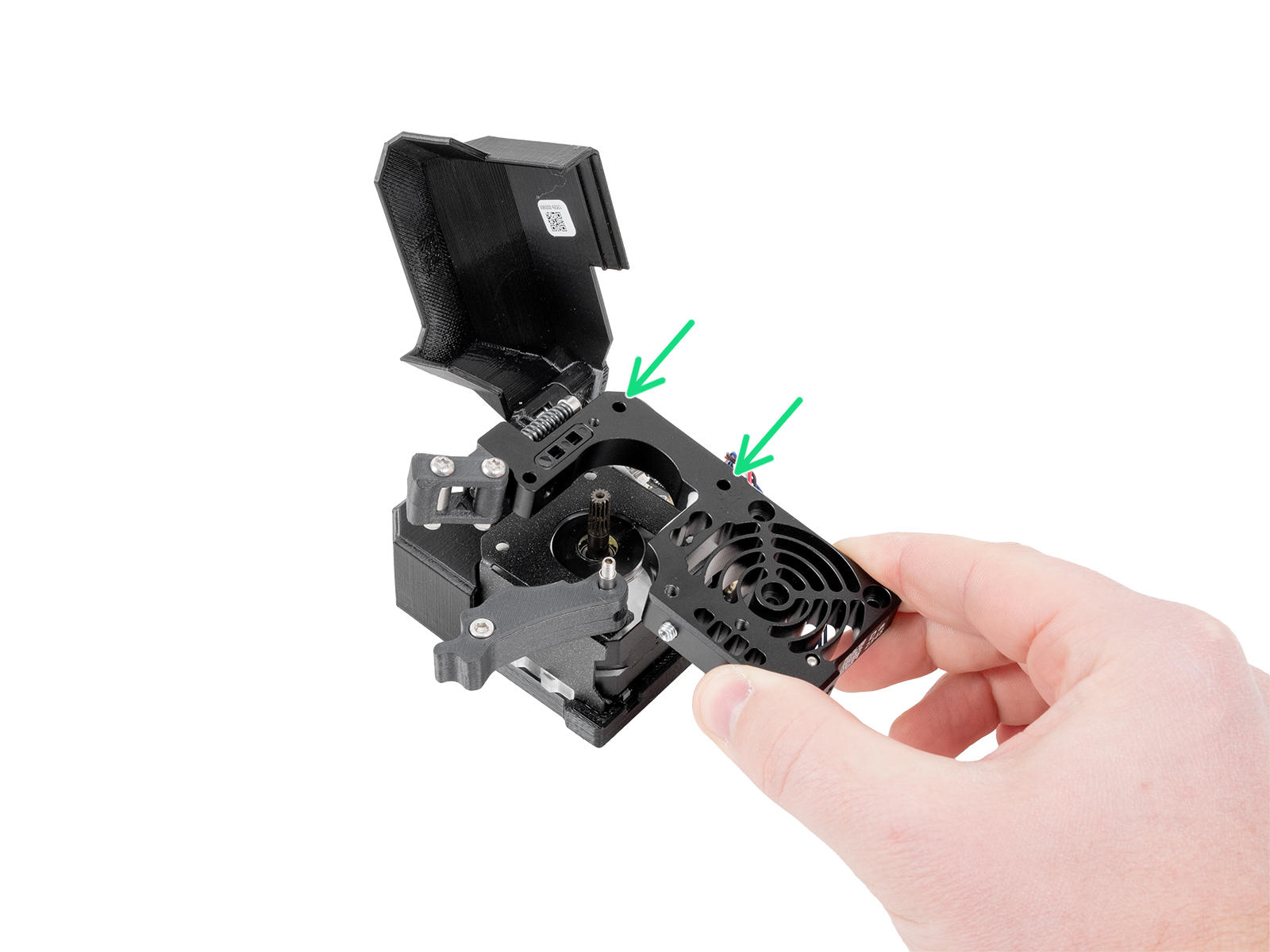

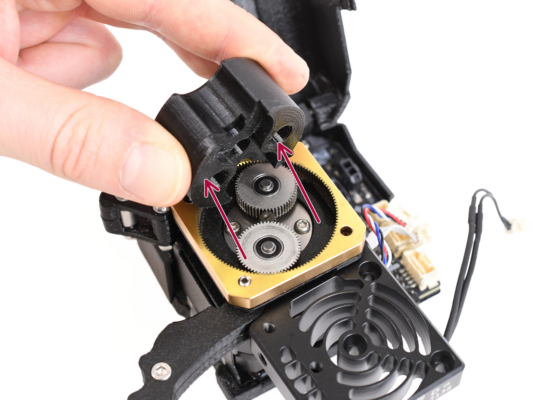

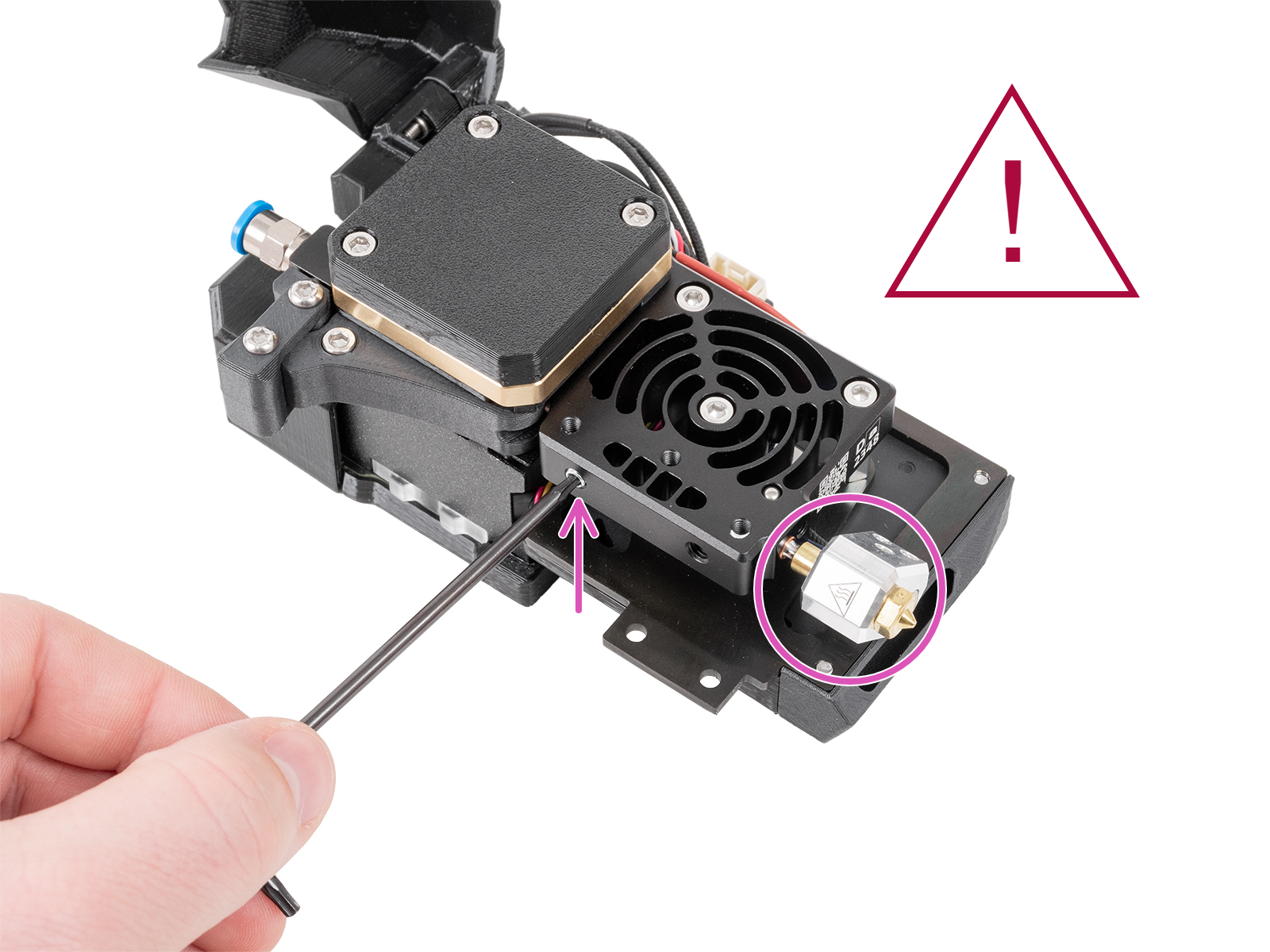

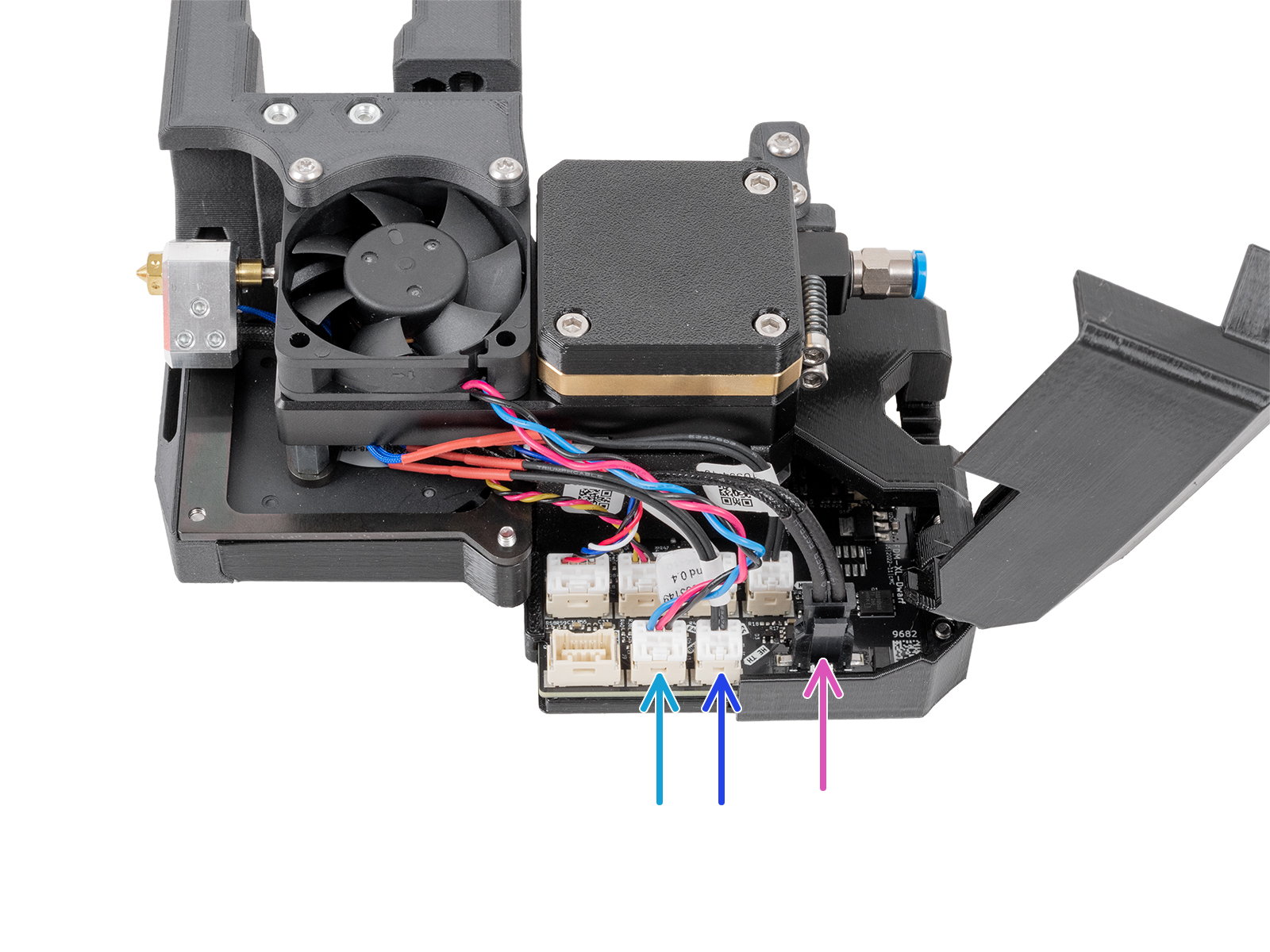

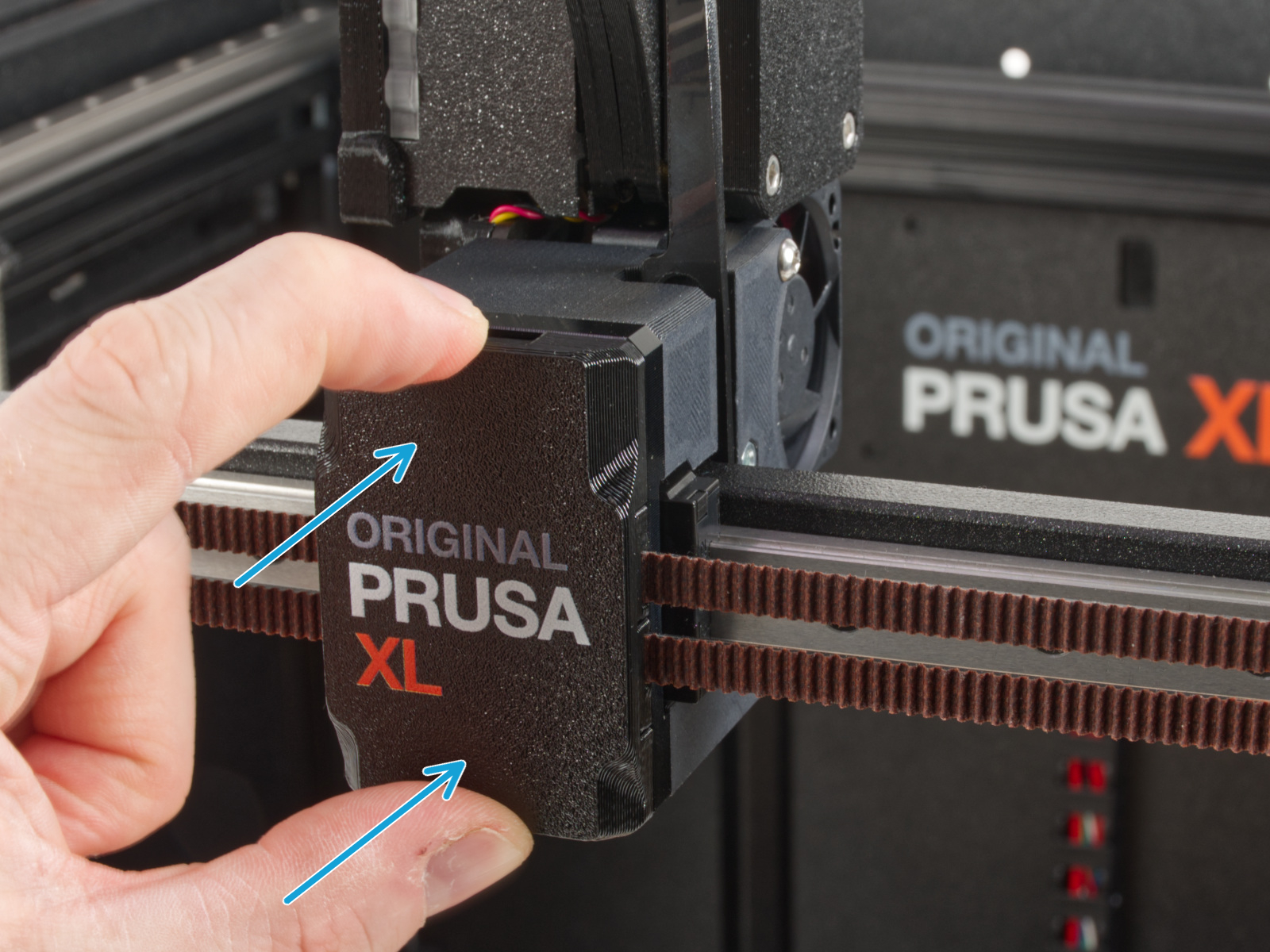

⬢This guide will take you through the replacement of the Heatsink on the Original Prusa XL (Single-tool).

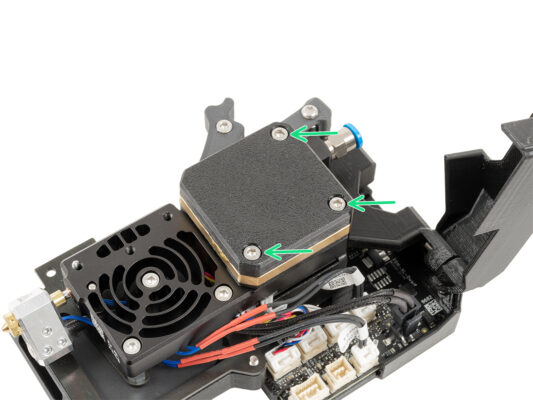

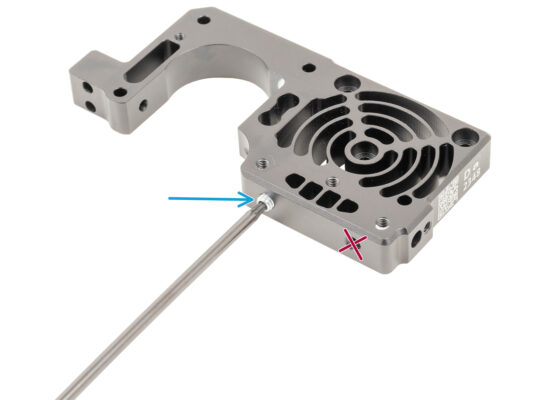

The following instructions are intended for XL Single-tool only, although most steps are common. If you have a Multi-tool XL, please go to How to replace Nextruder heatsink (XL Multi-tool)

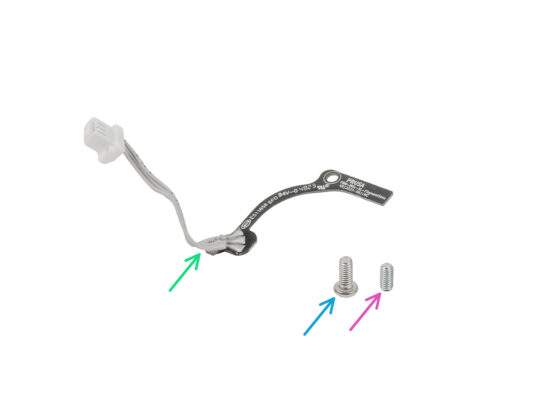

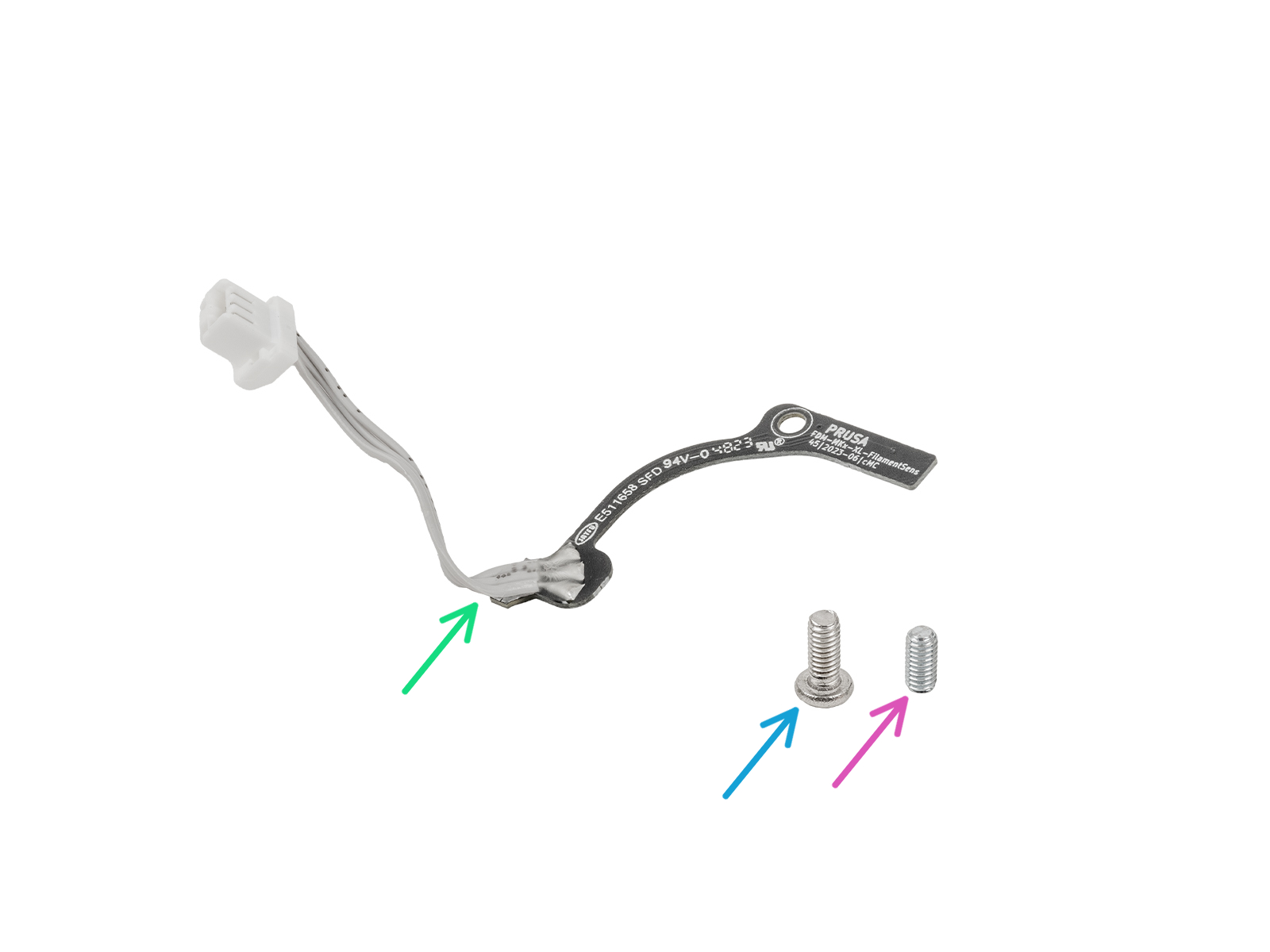

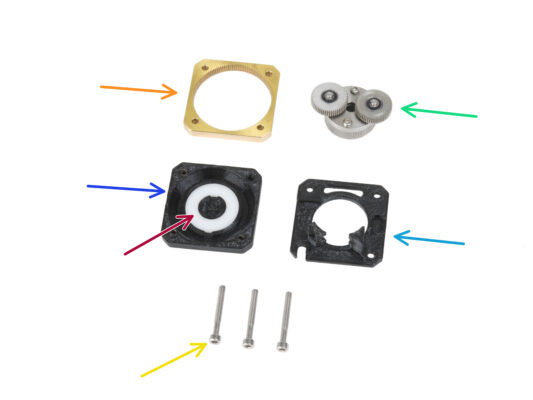

Some parts might slightly differ. However, it does not affect the procedure.

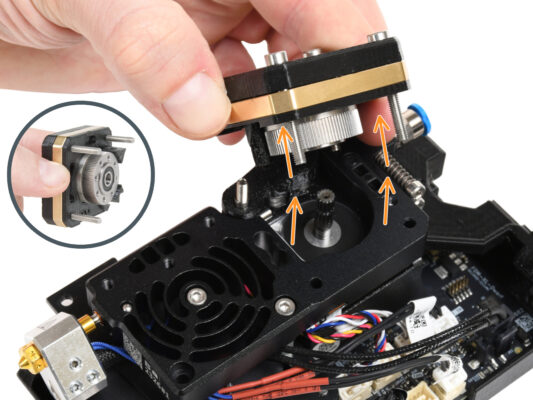

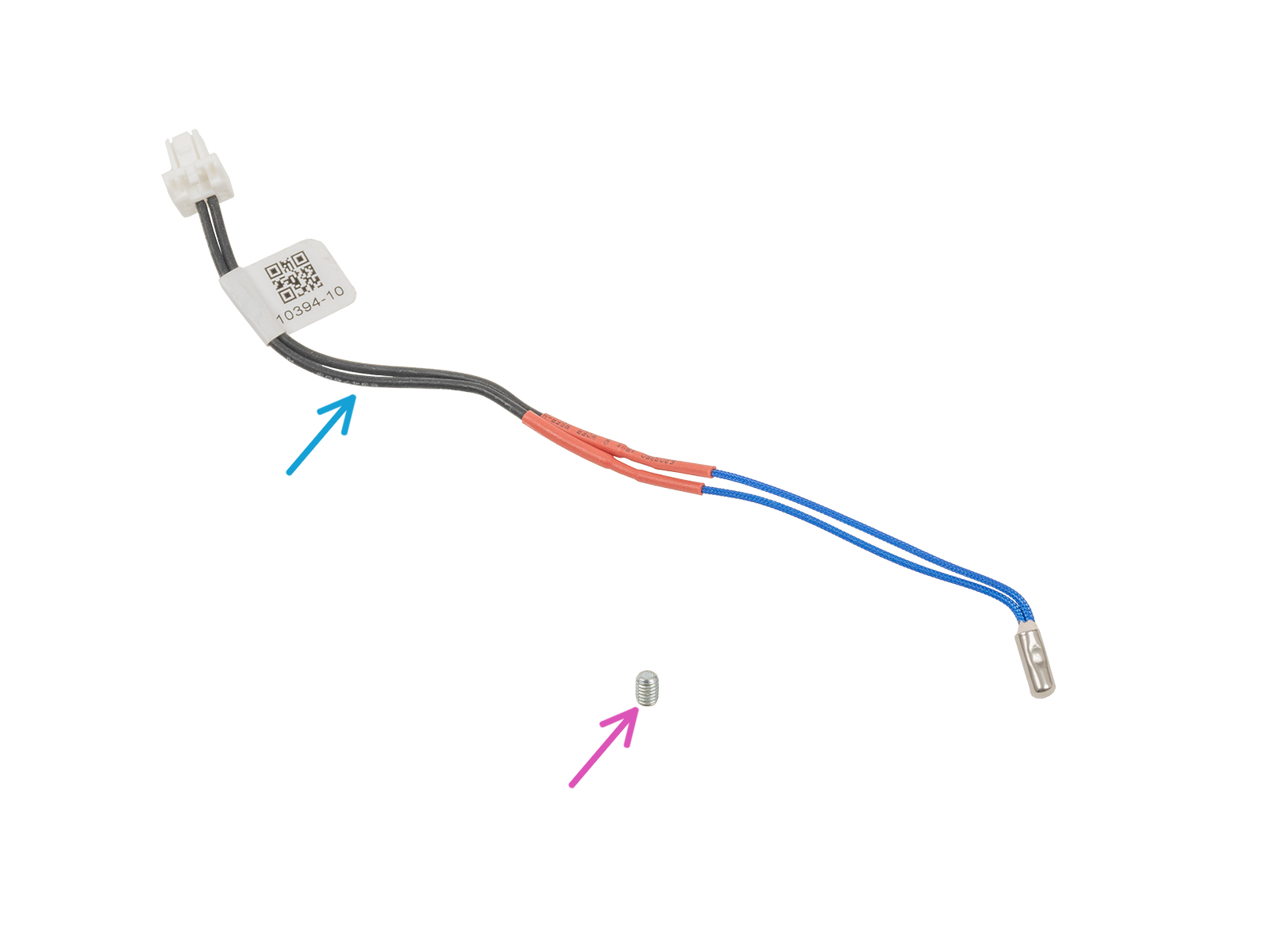

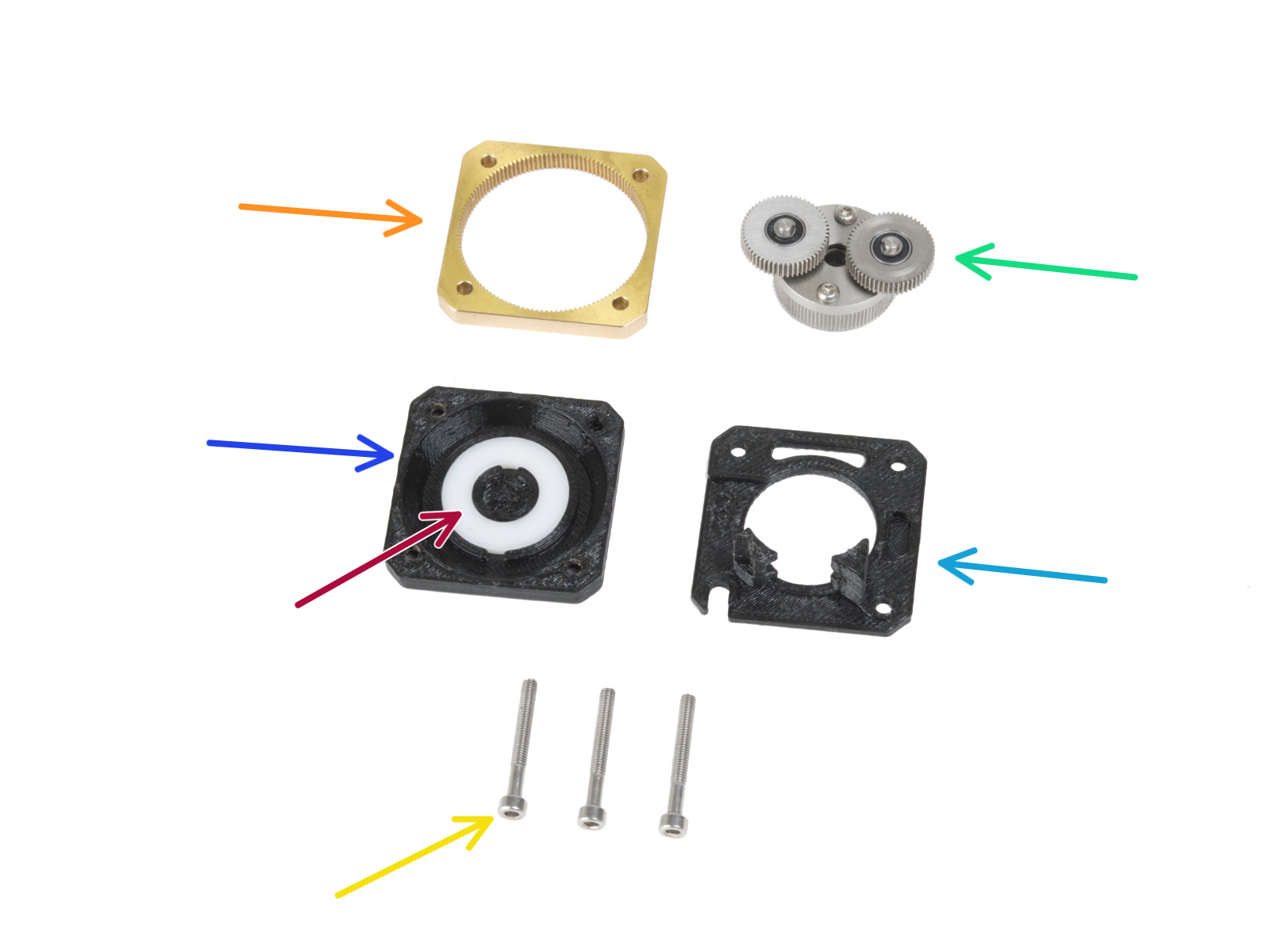

All necessary parts are available in our e-shop prusa3d.com.

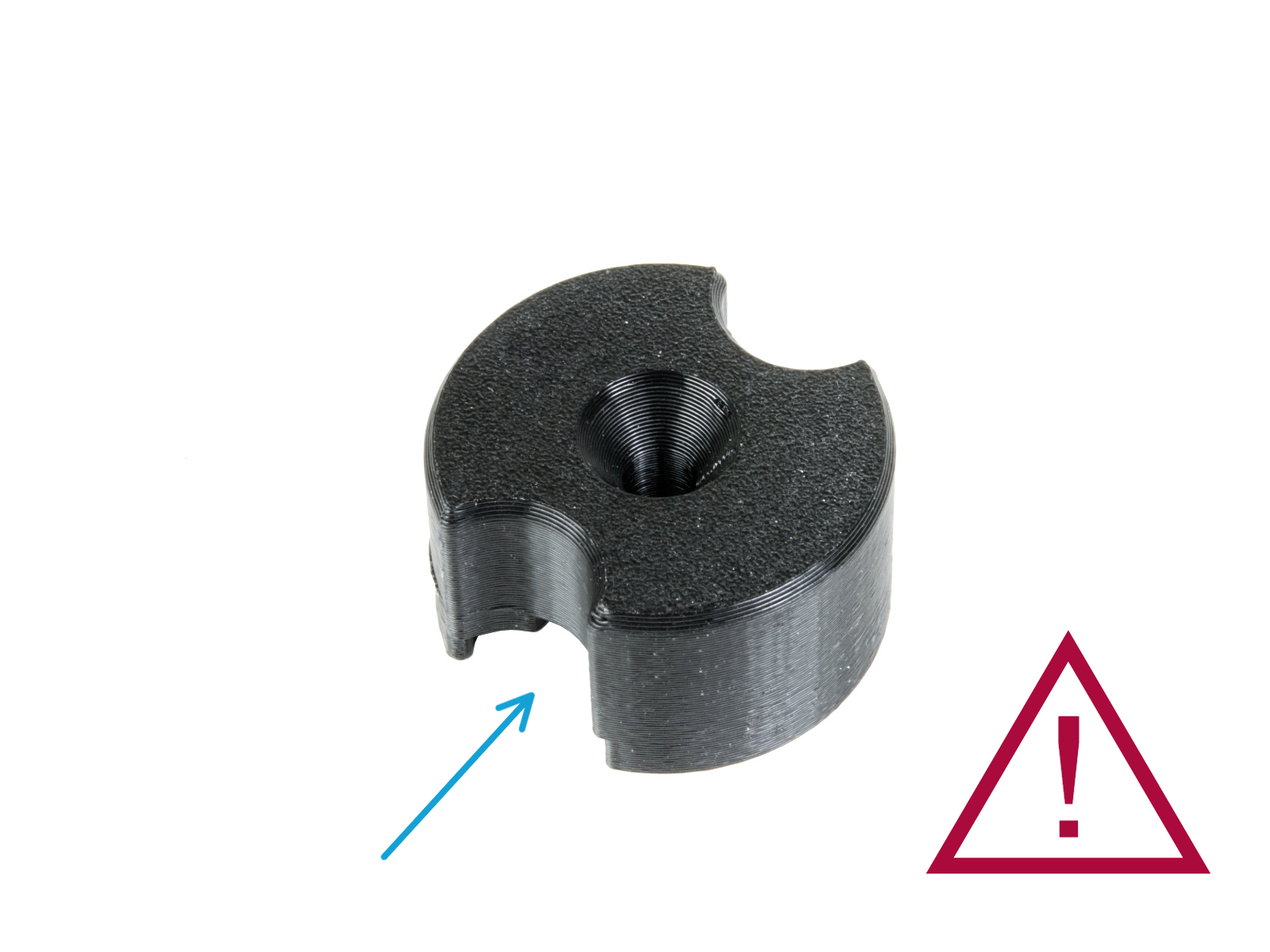

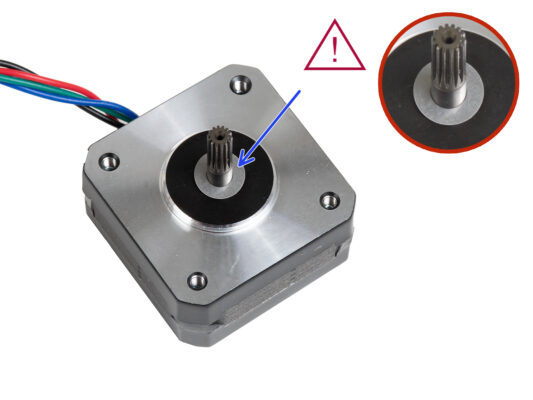

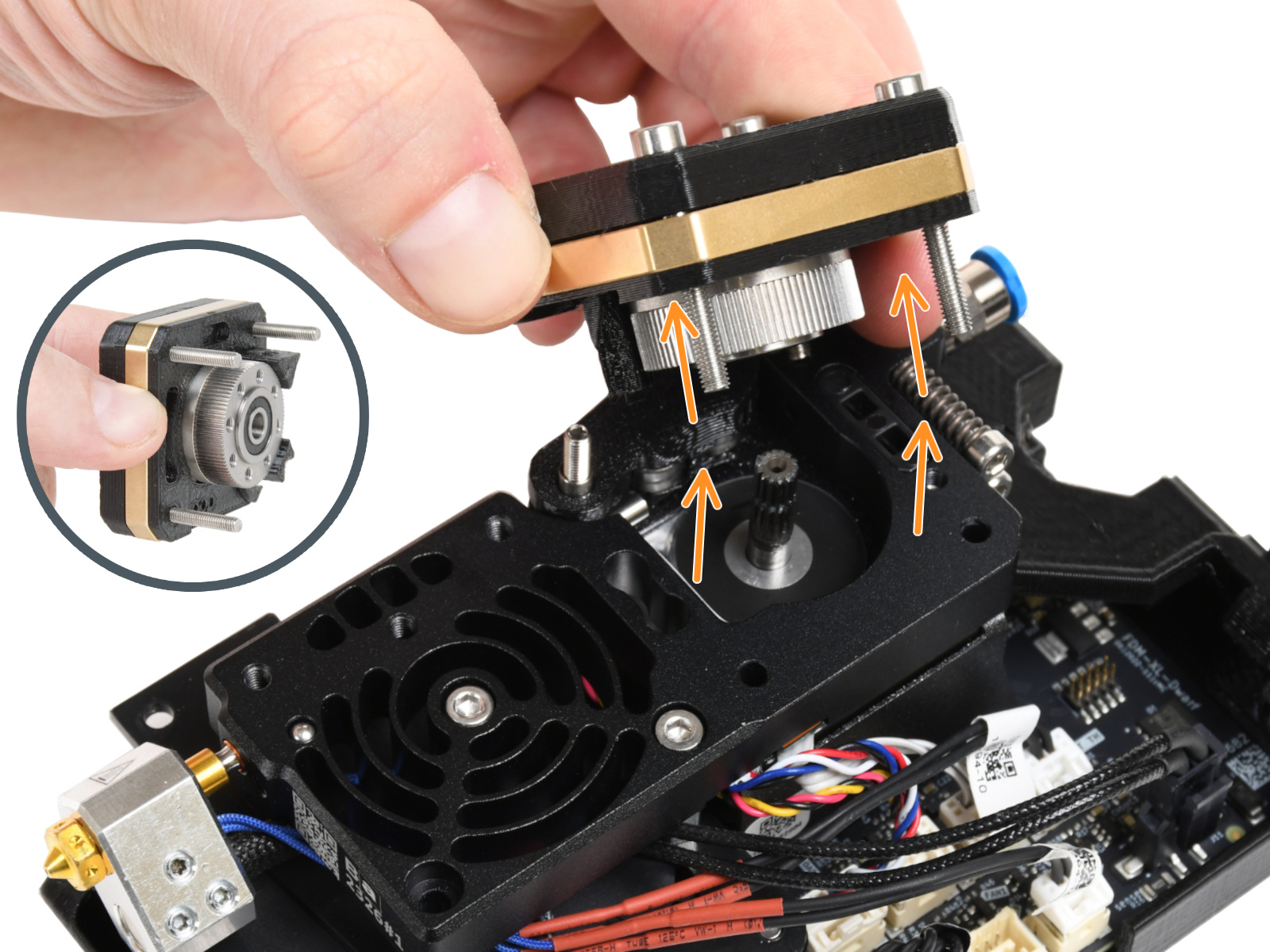

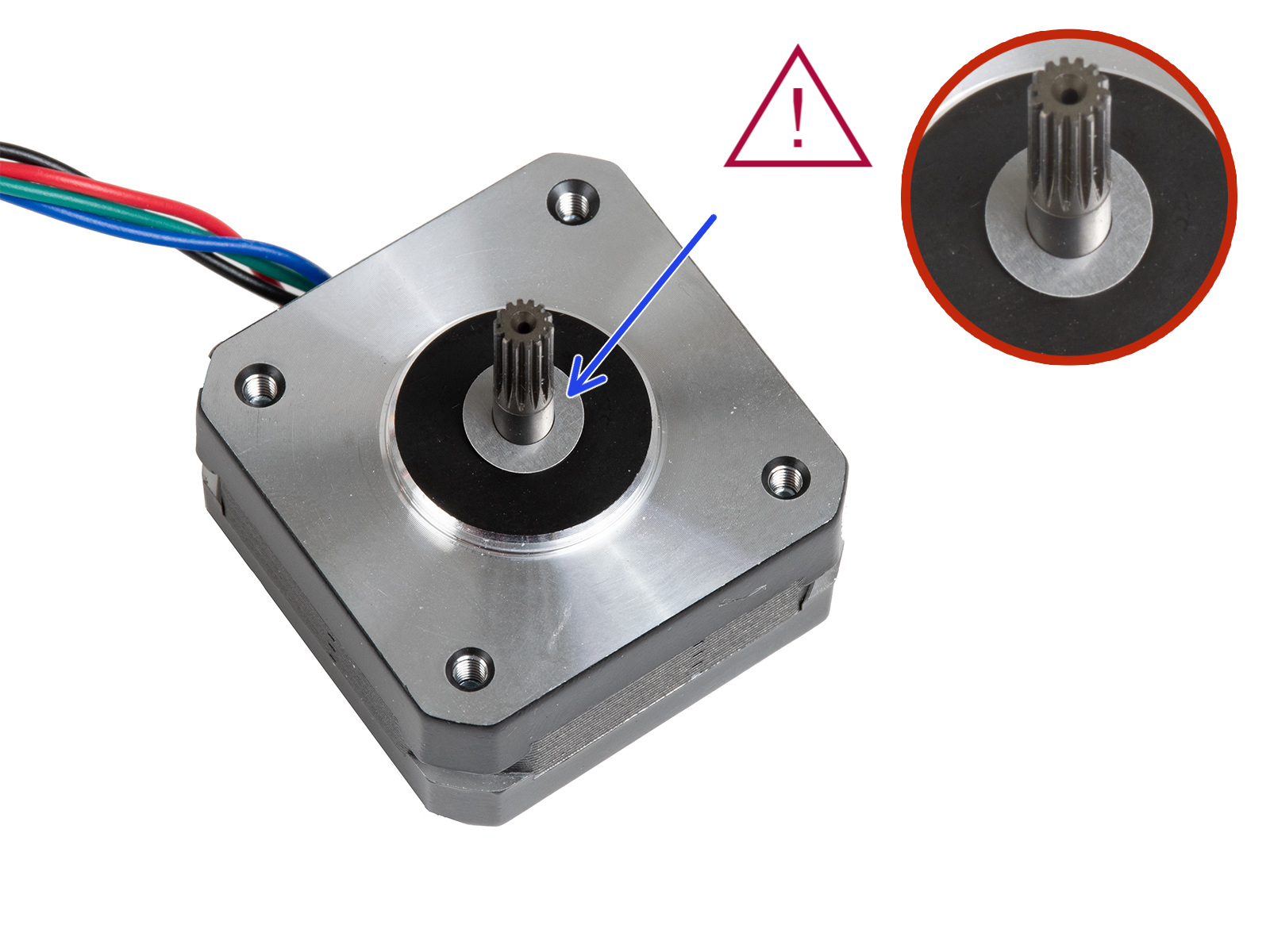

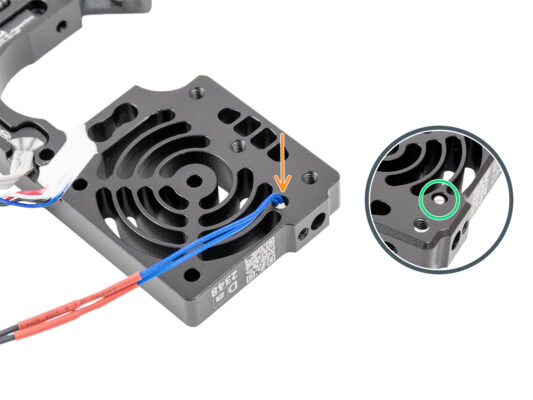

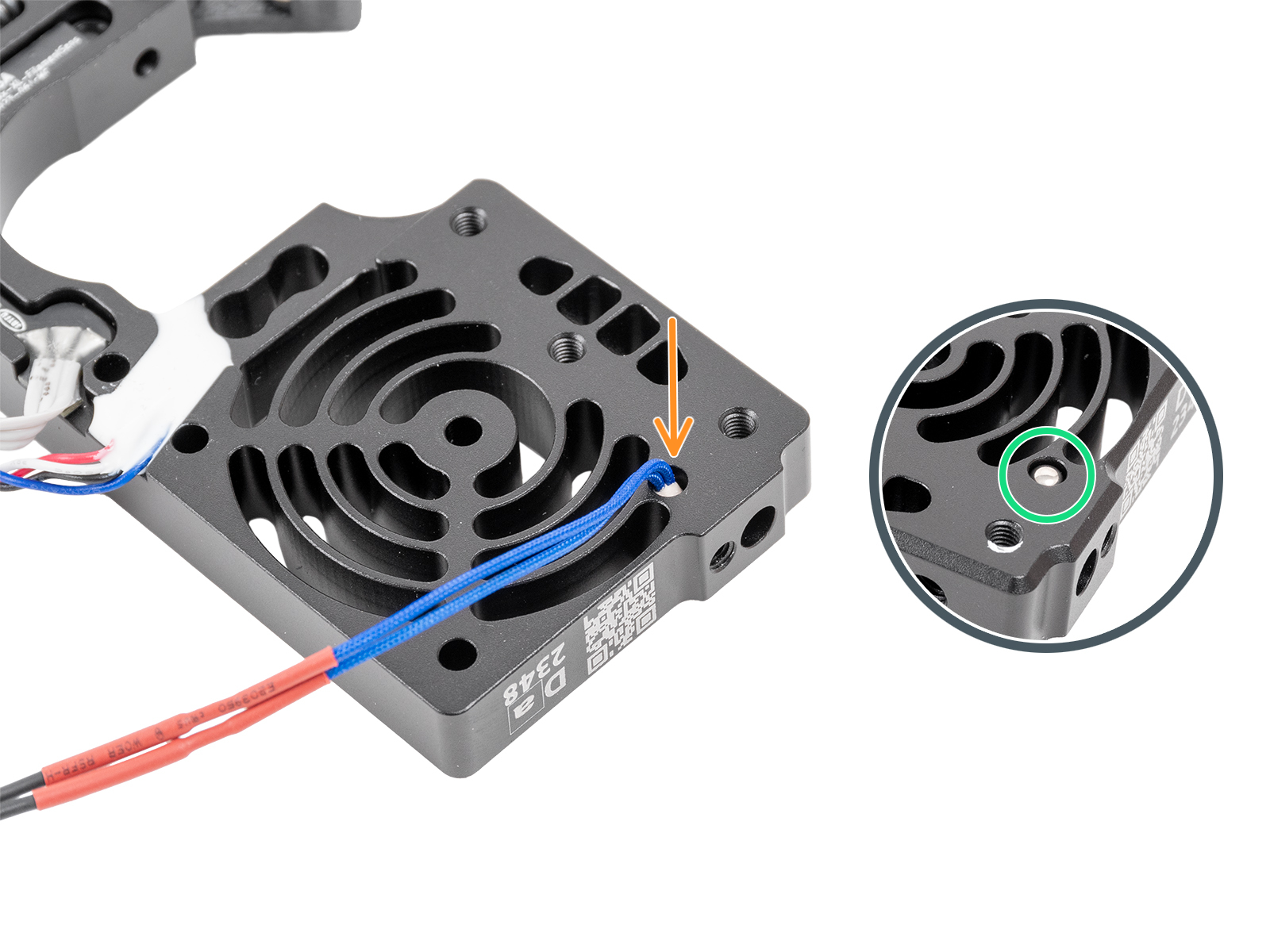

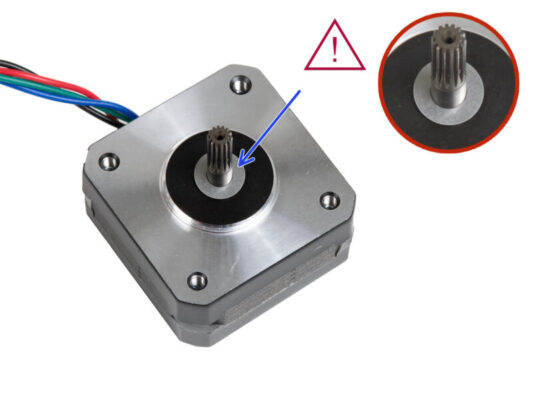

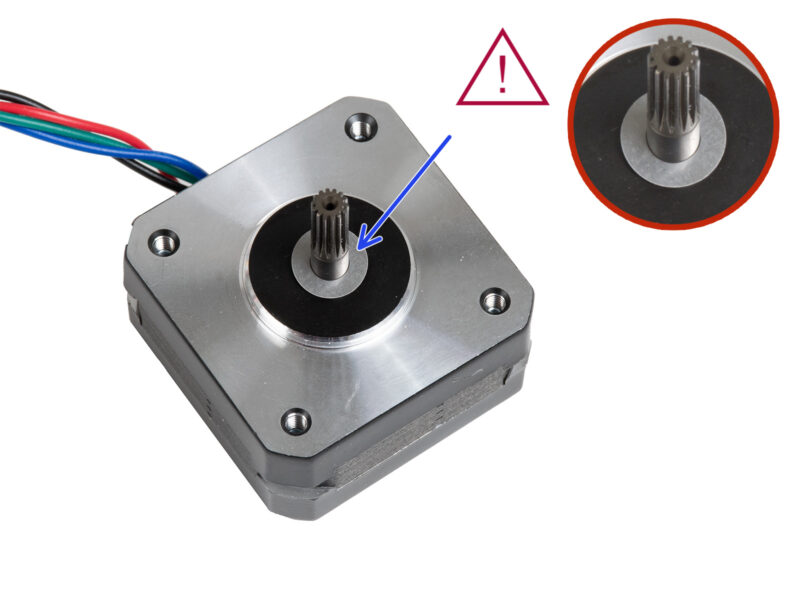

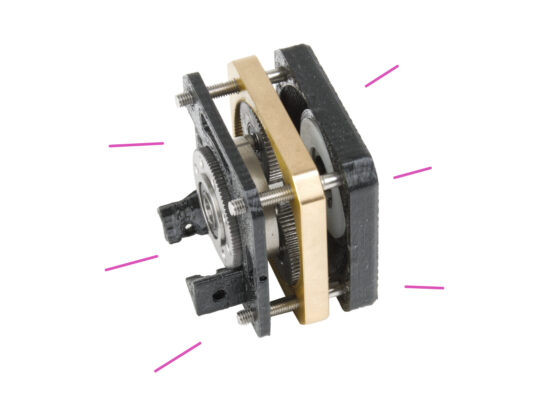

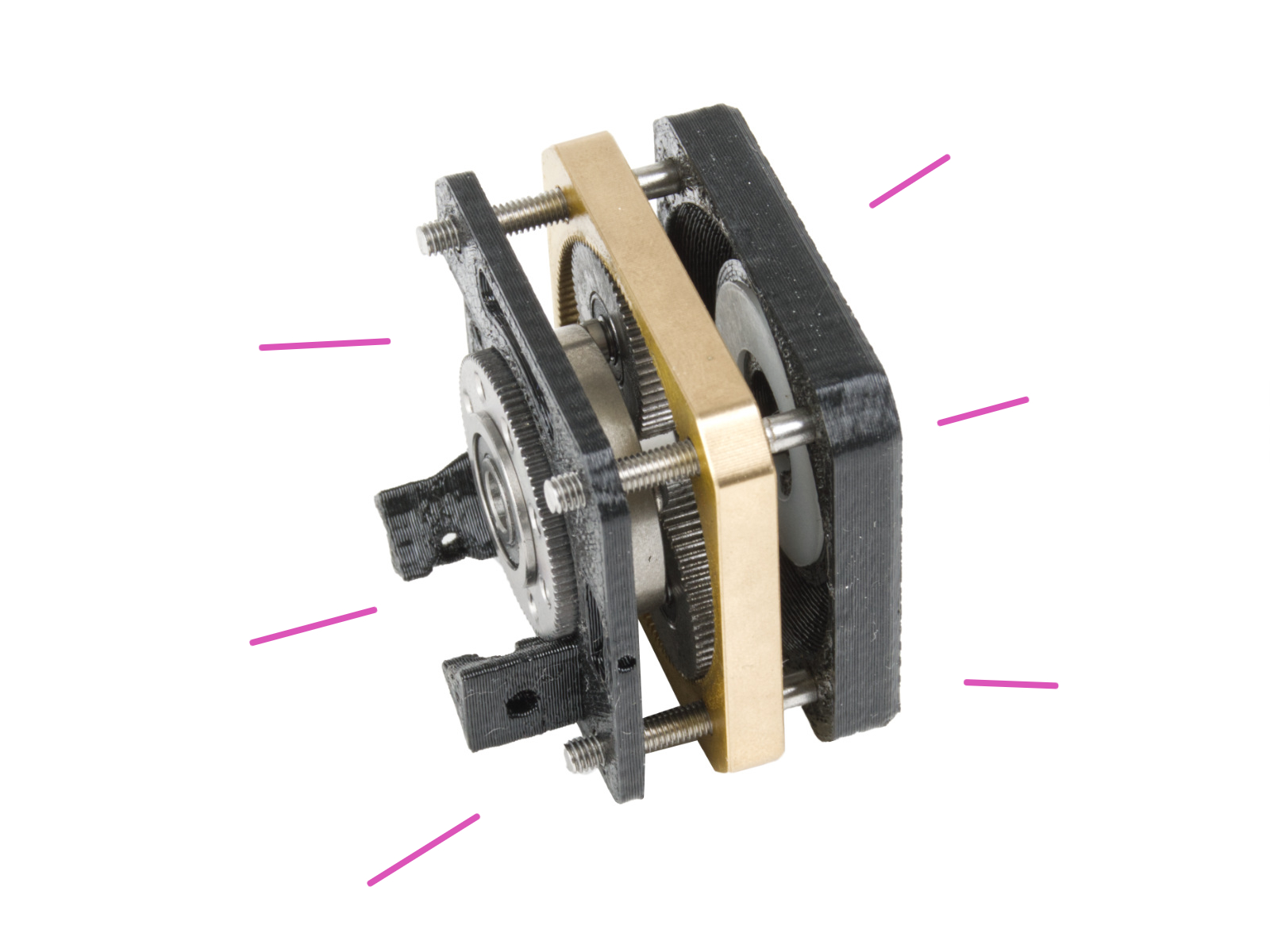

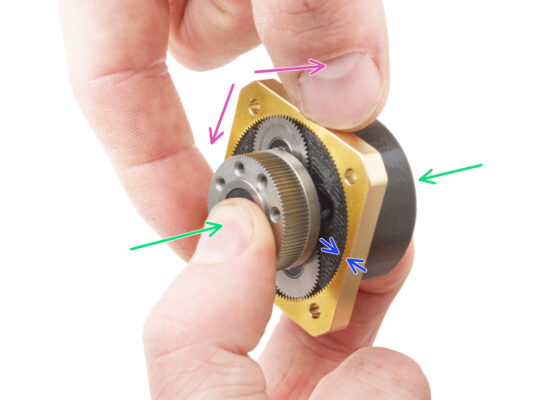

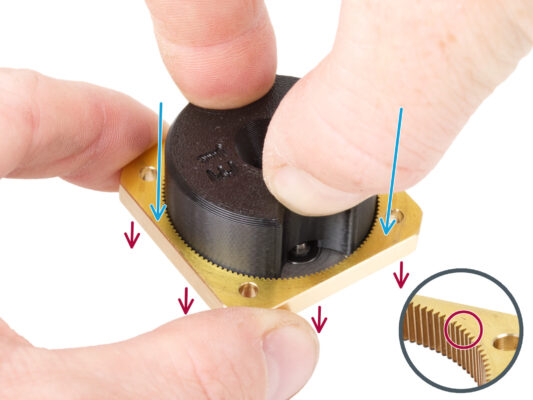

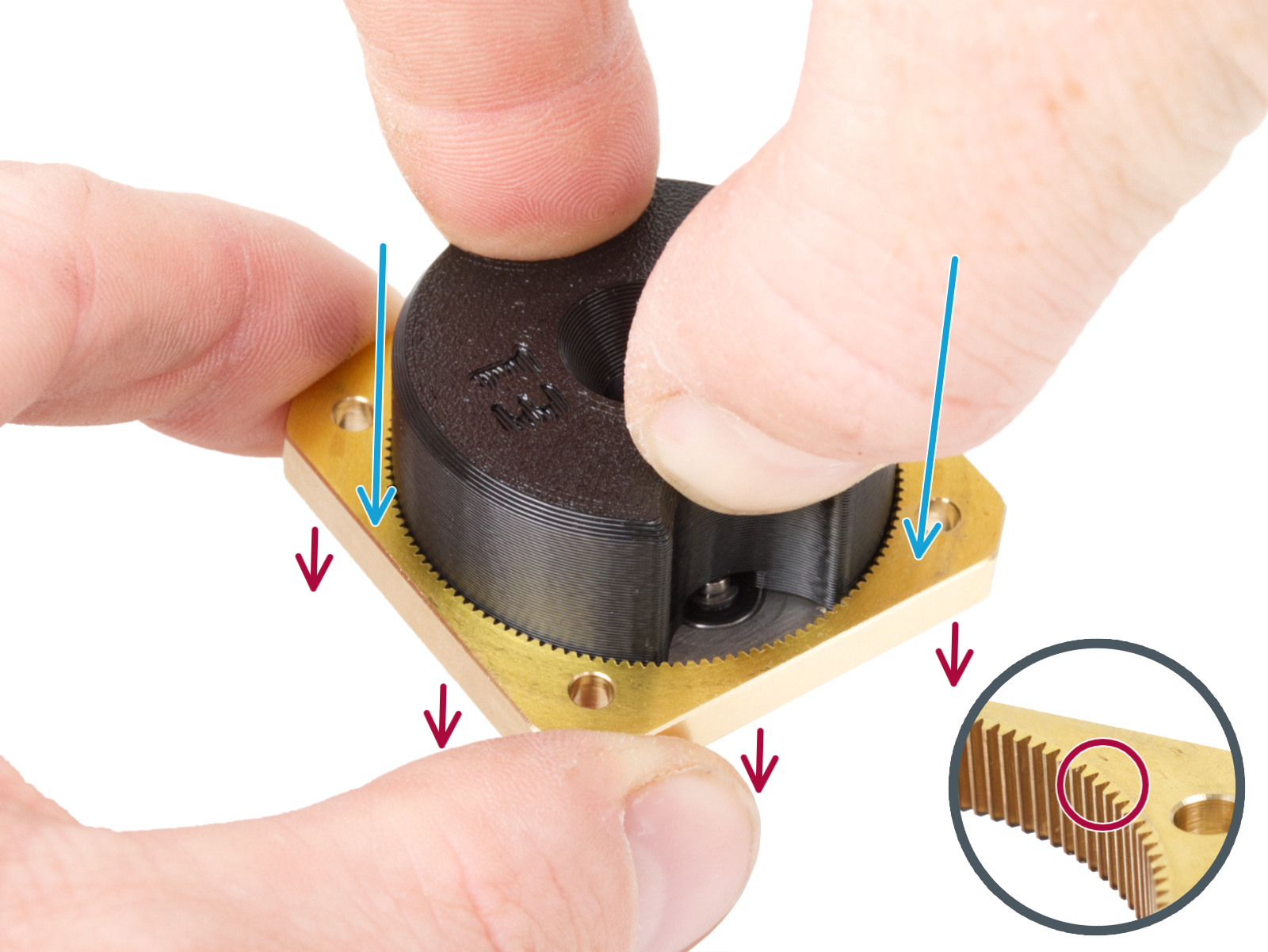

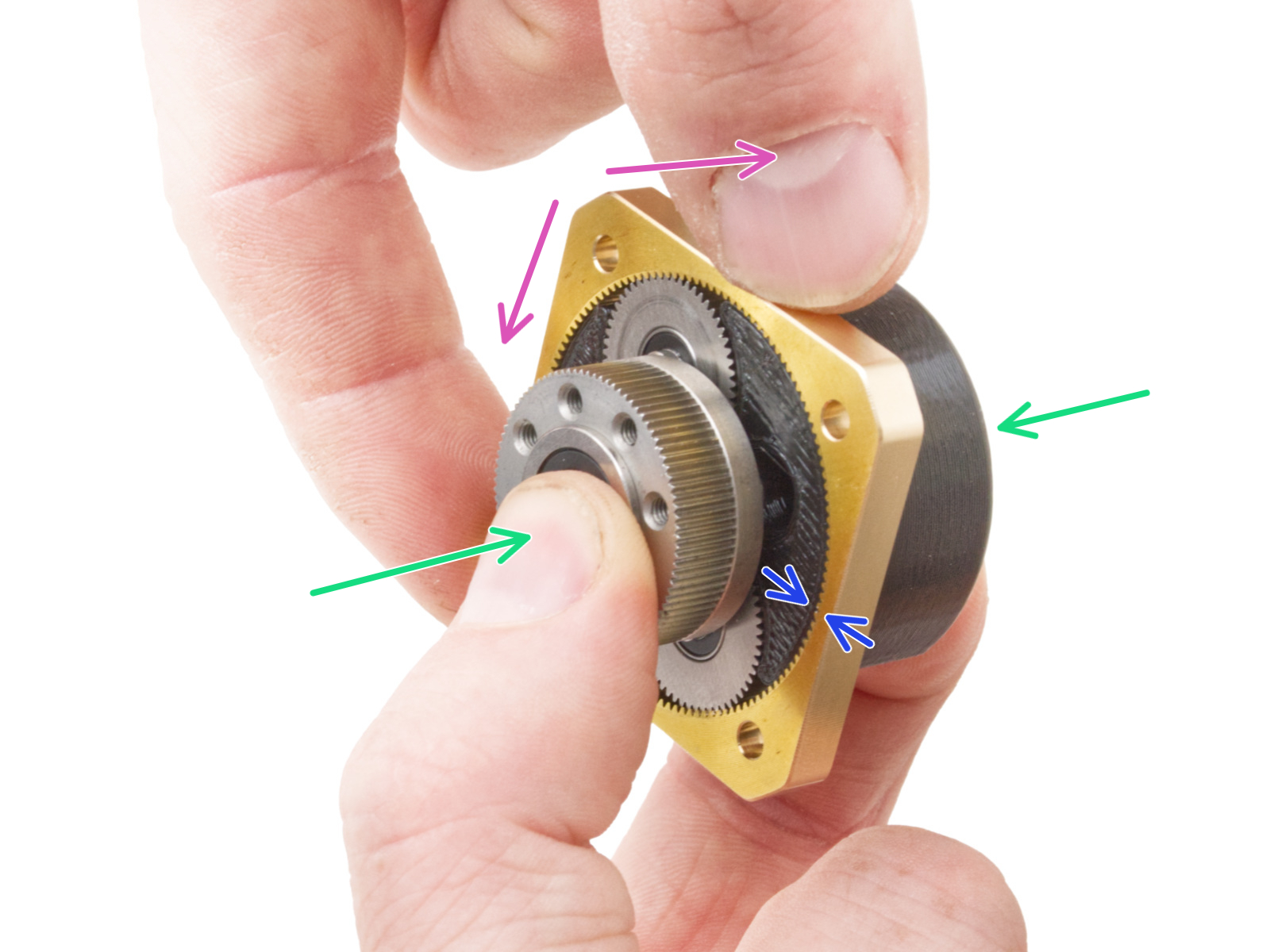

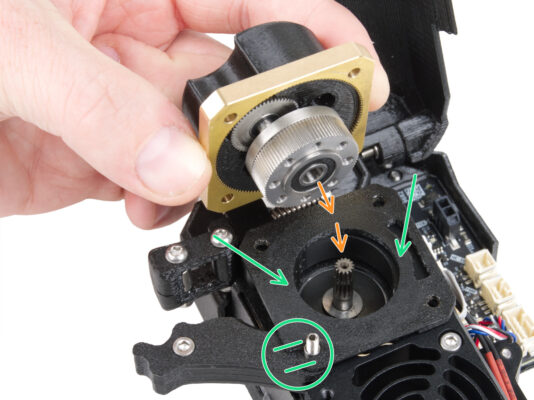

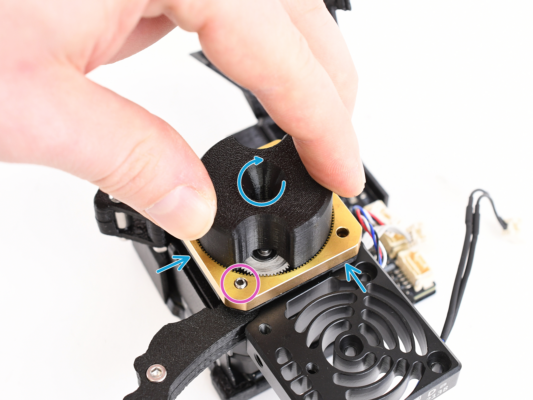

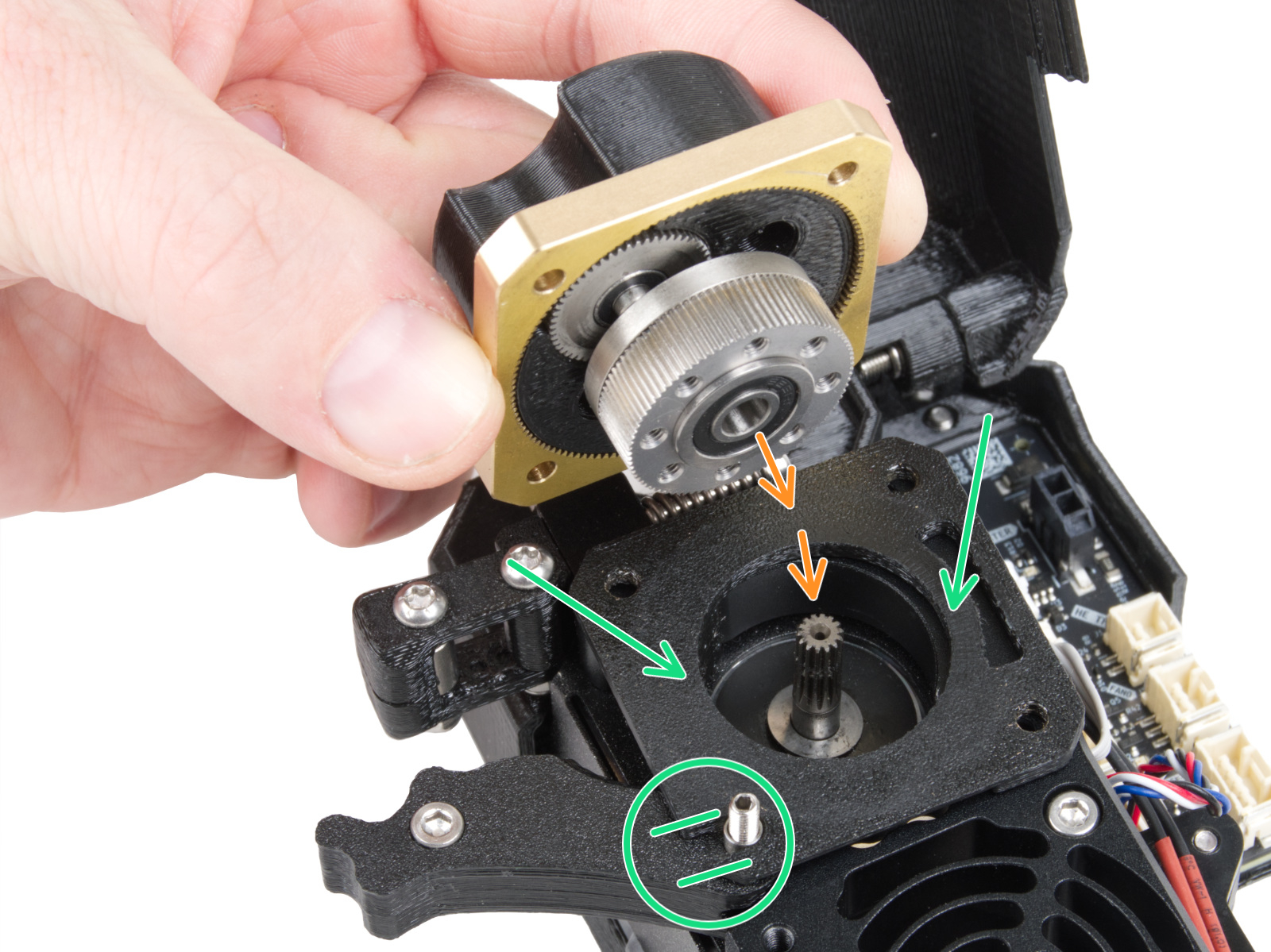

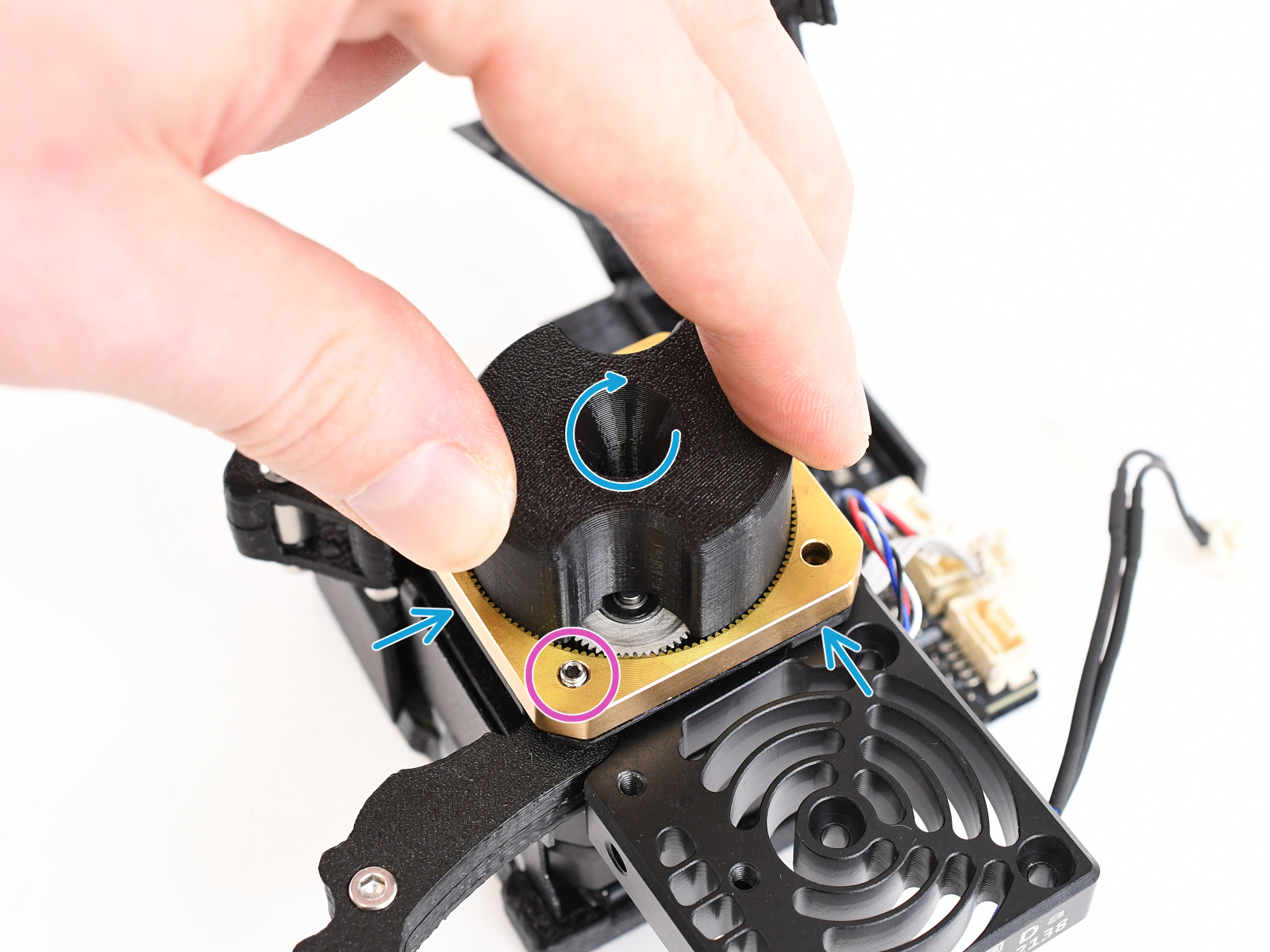

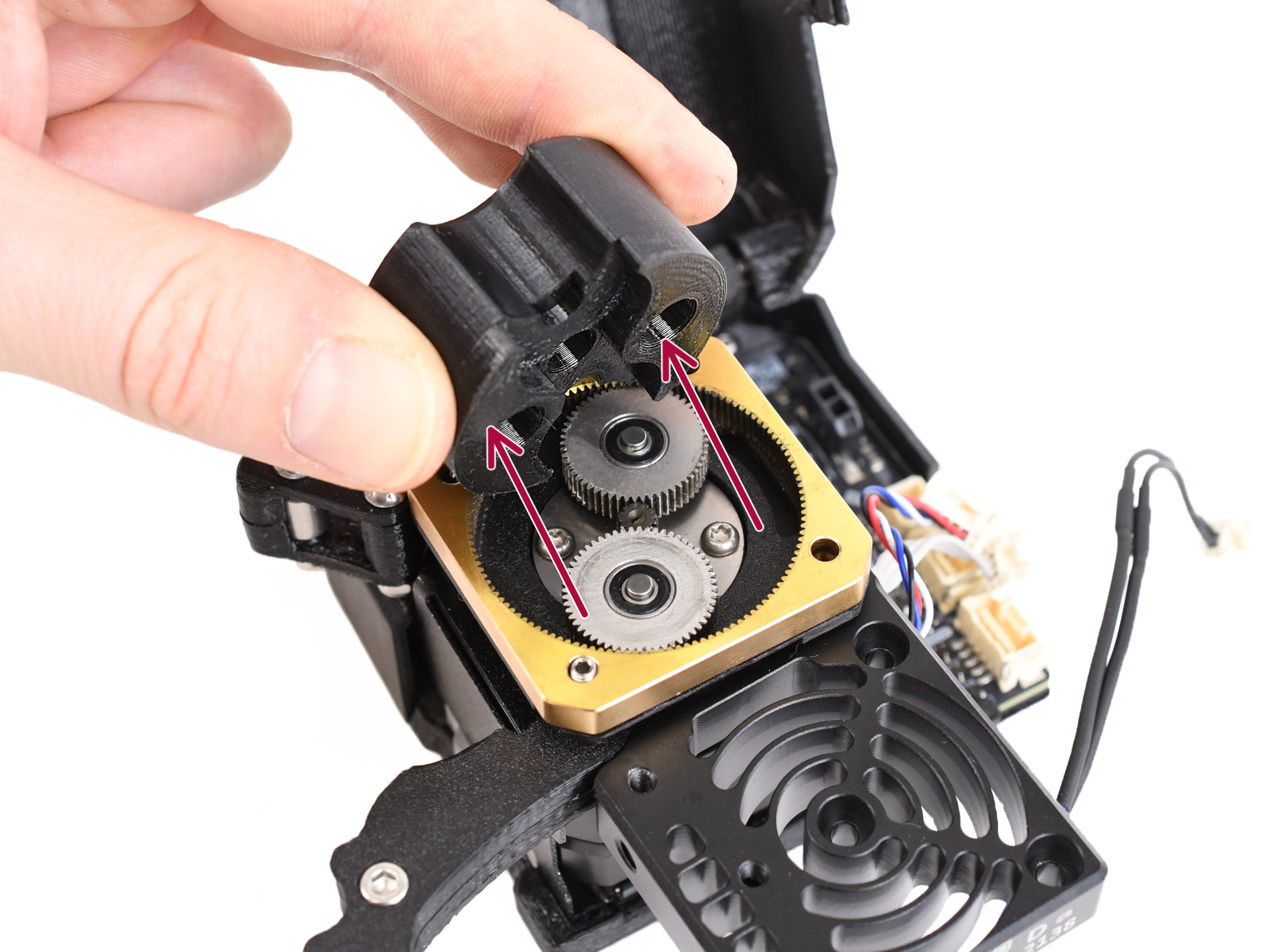

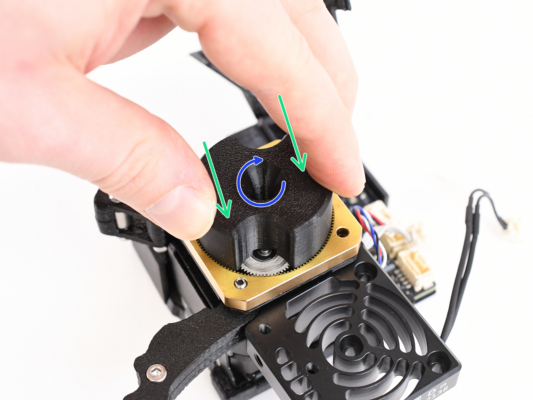

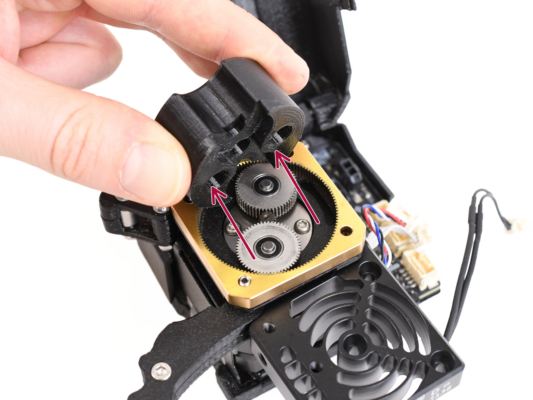

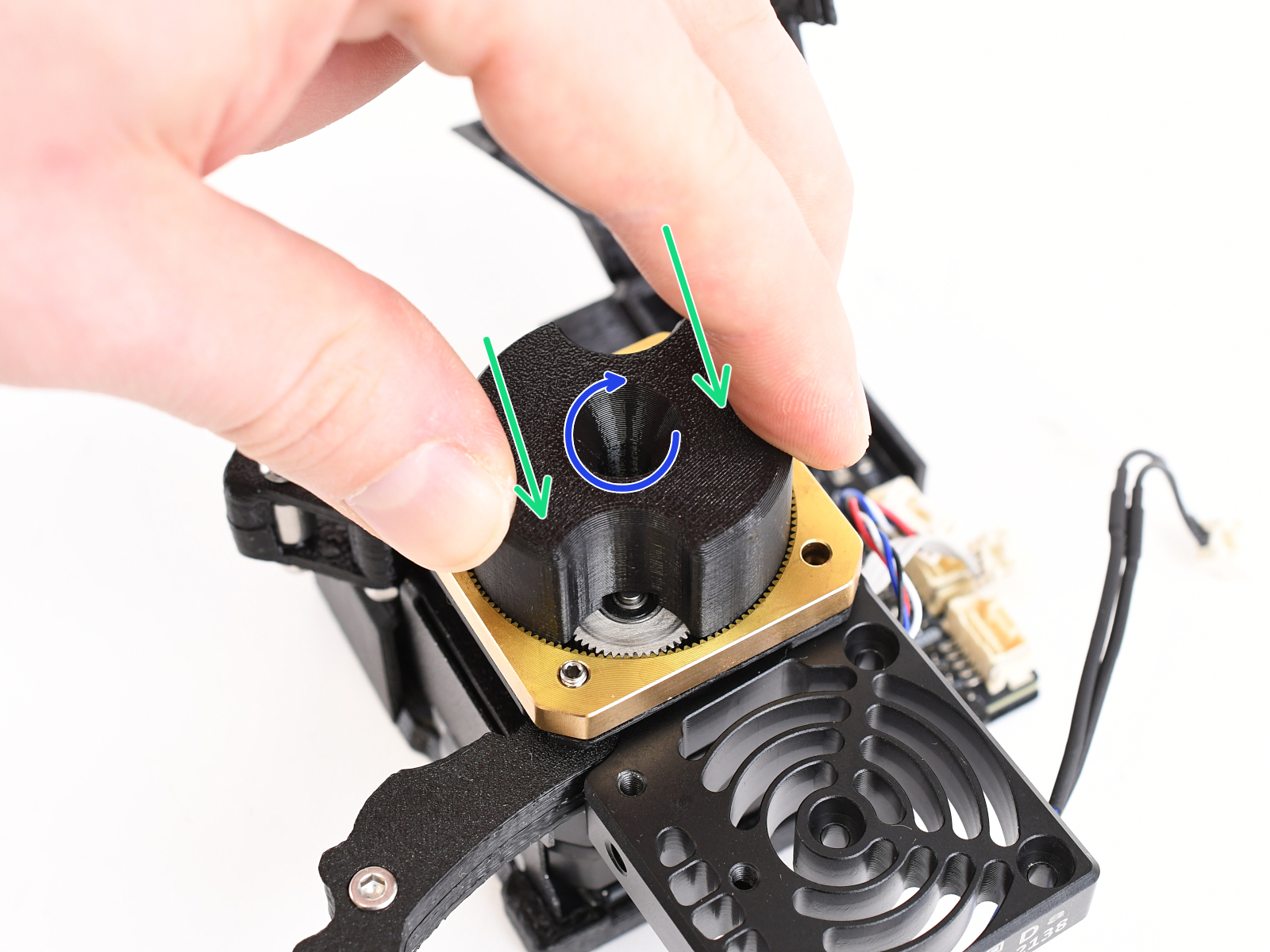

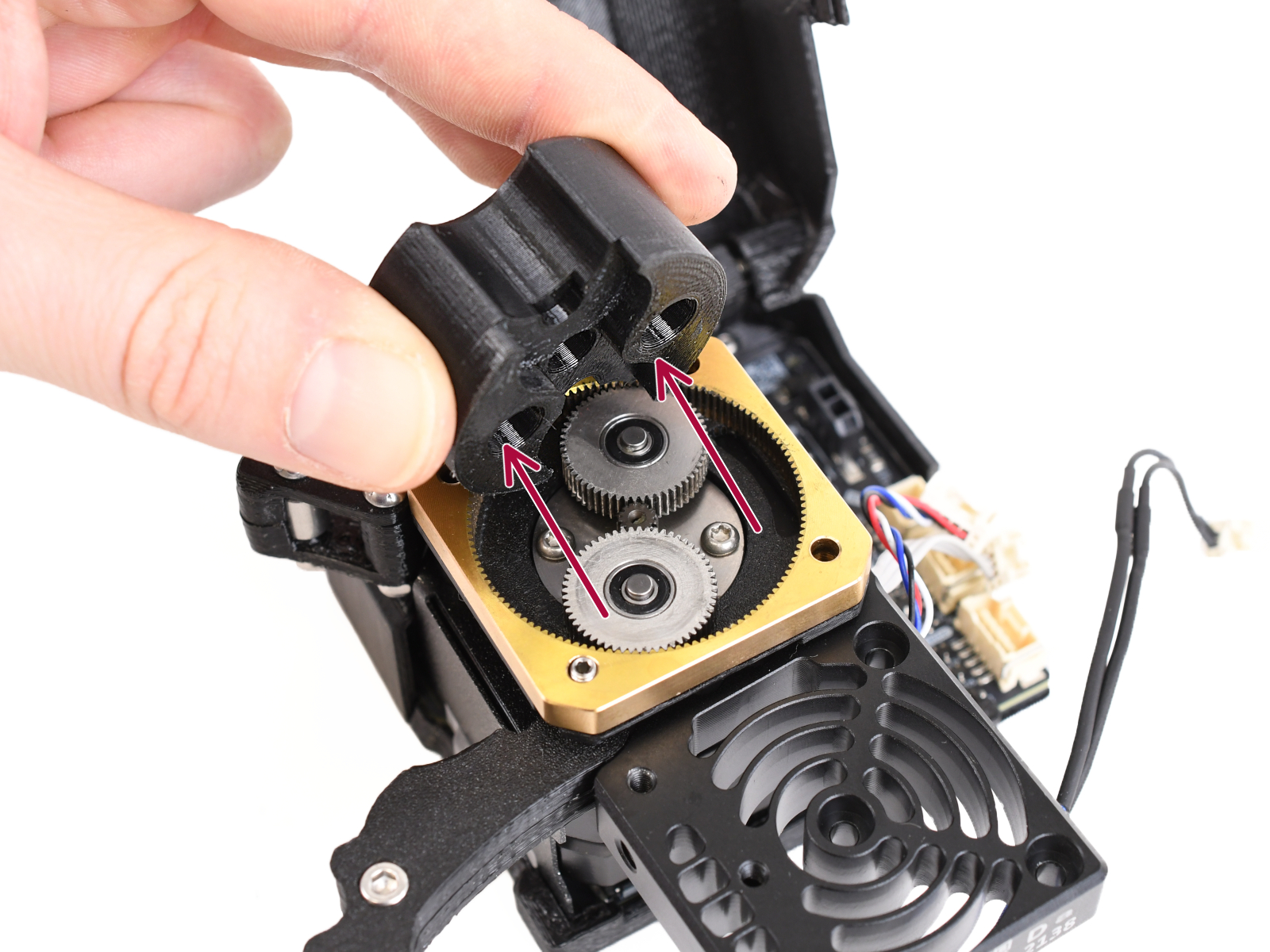

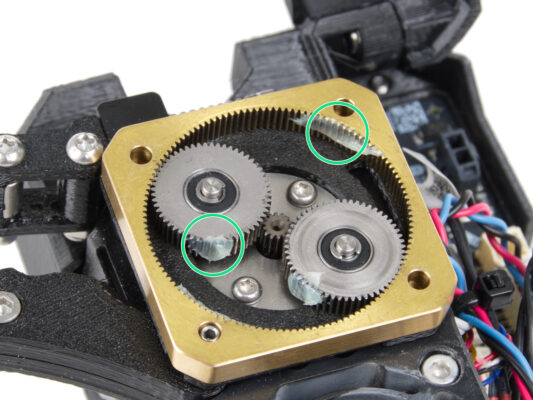

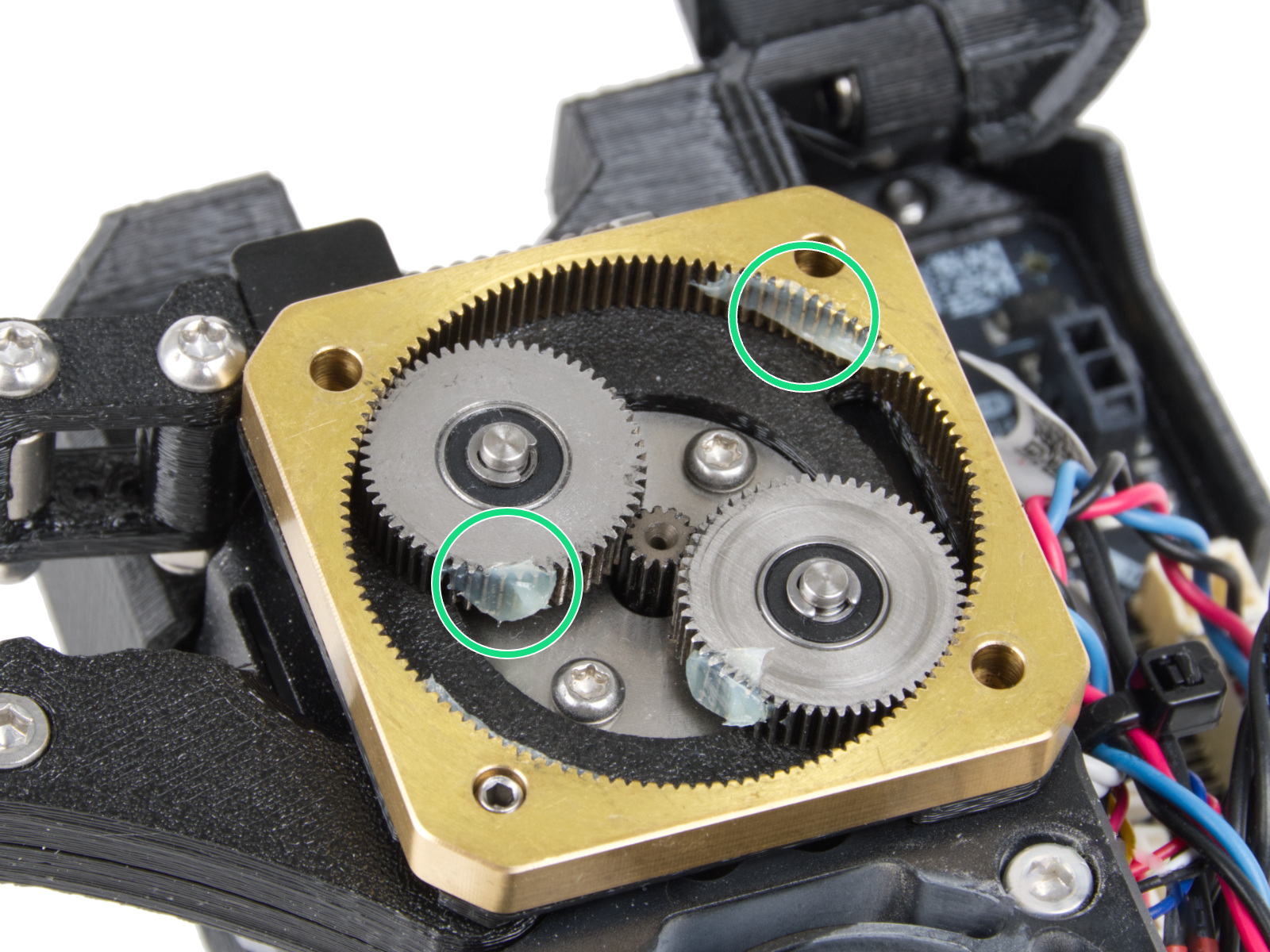

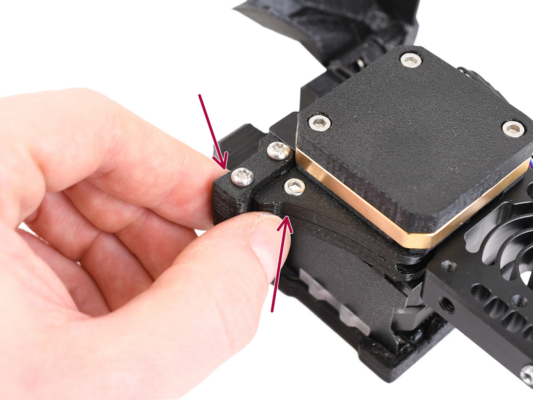

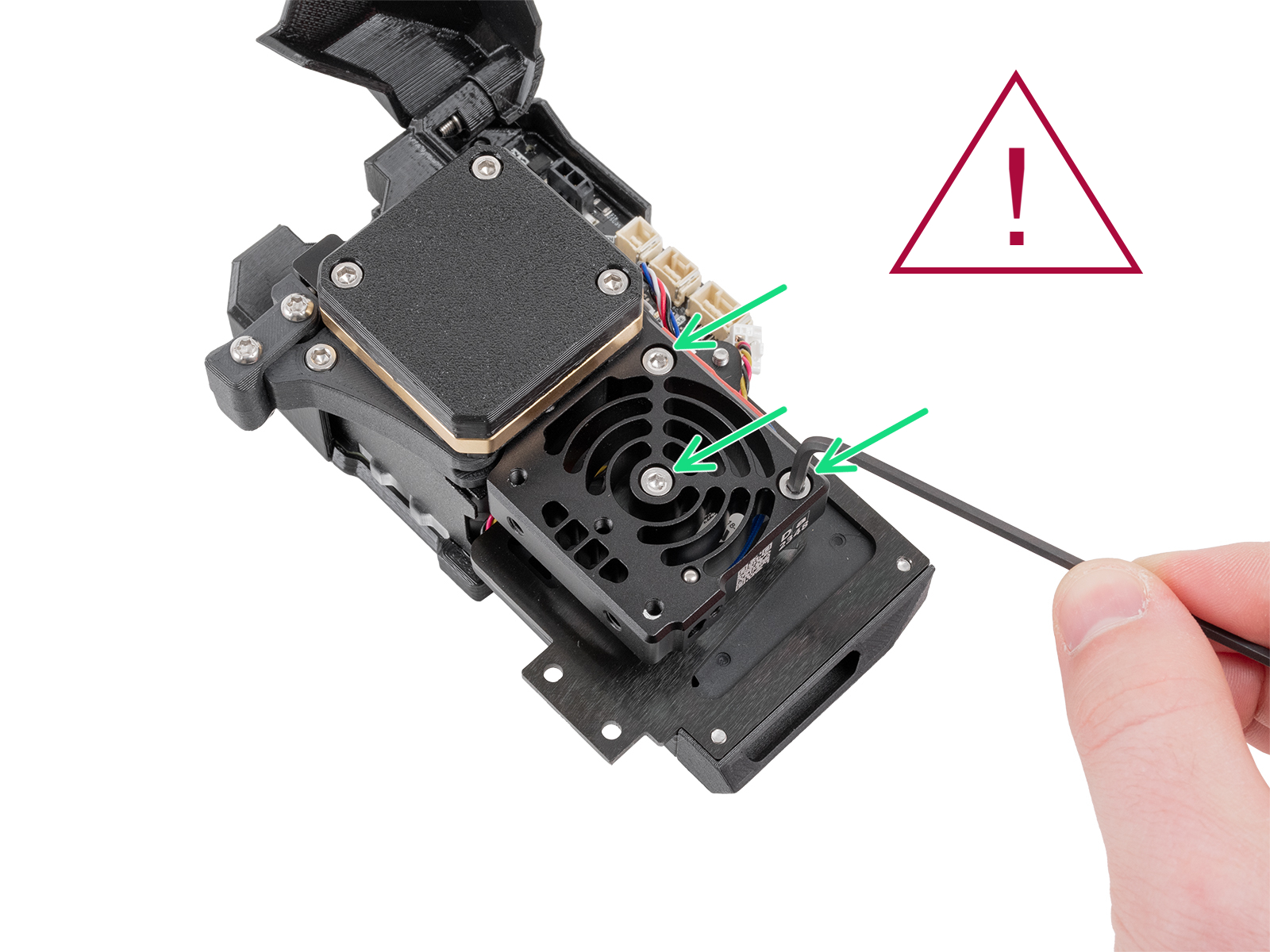

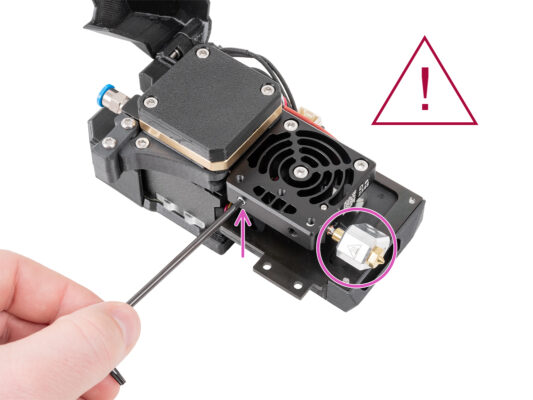

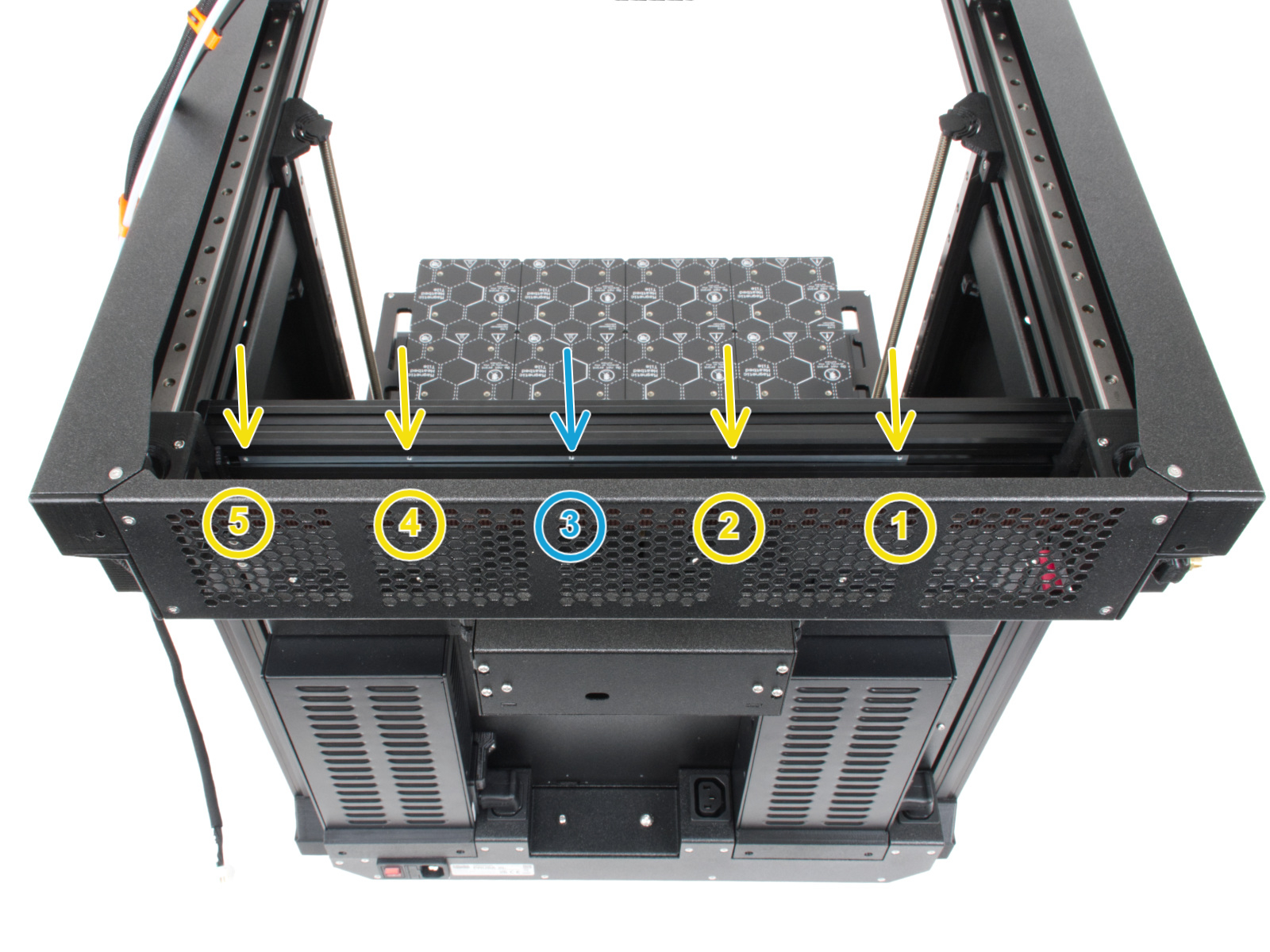

The following instructions require extreme attention. The procedure involves direct intervention in the planetary gearbox.