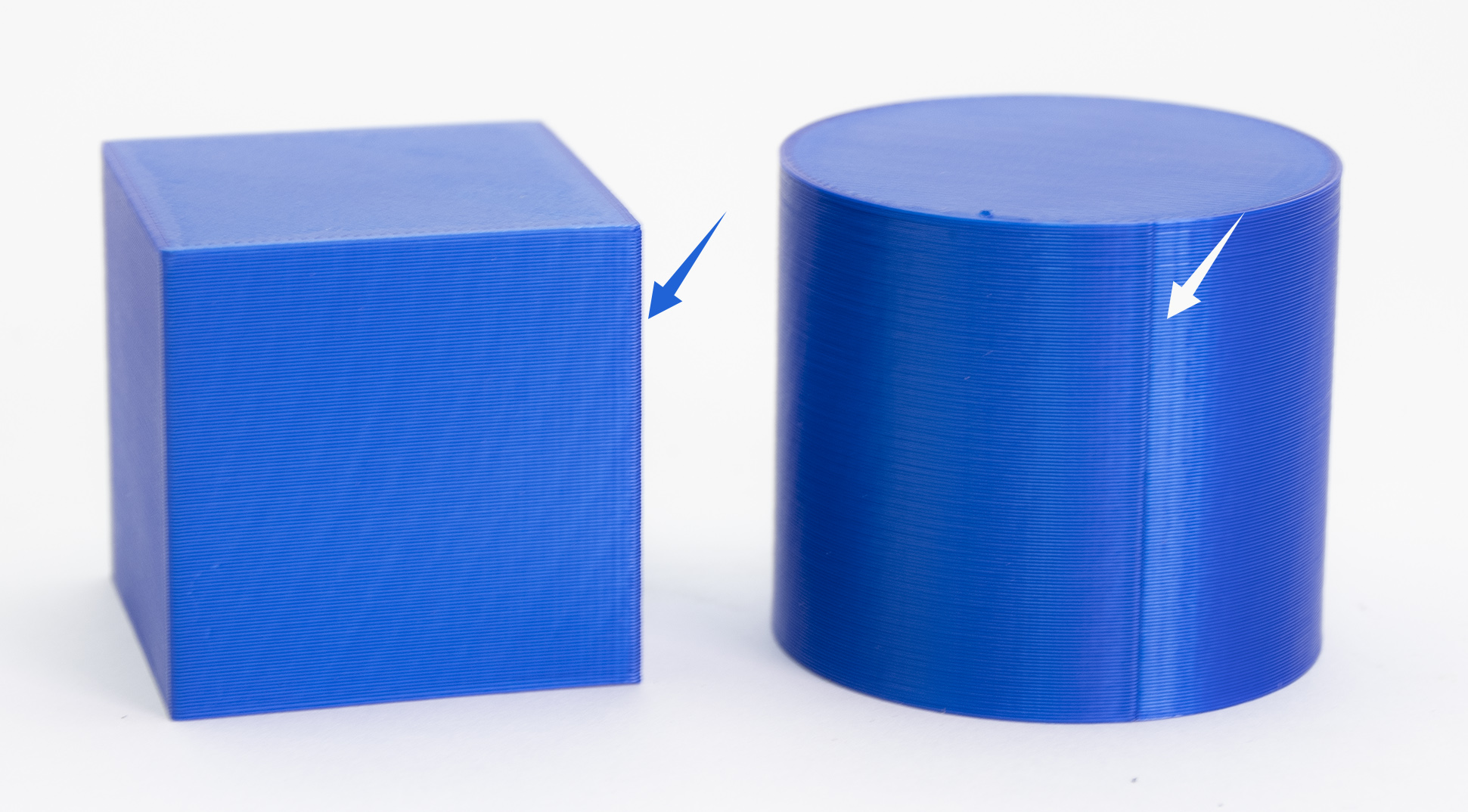

Unless you're printing in the Spiral vase mode, each perimeter loop has to start and end somewhere. This start/endpoint creates a potentially visible vertical seam on the side of the object. It's also commonly called zits, layer seams, or scars.

This seam will be obvious if the object's shape is cylindrical, without any sharp corners.

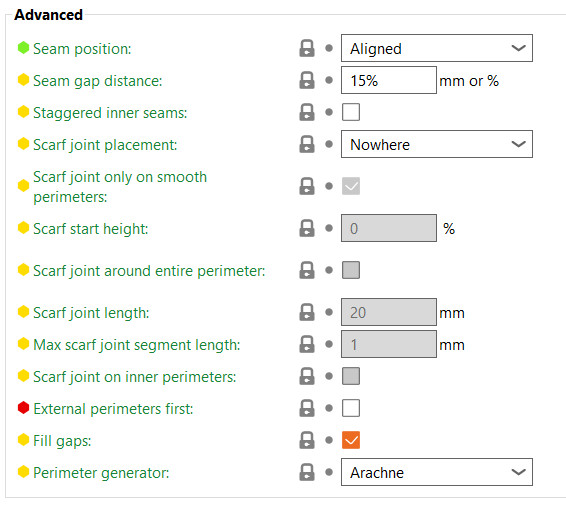

To hide the seam as much as possible, there are several seam placement options available in

Print settings -> Layers and perimeters -> Seam position. Note that some options will only appear when Expert mode is selected.

Seam Position

Nearest (edge)

Attempts to place the seam on the nearest edge of the current layer. If your model has sharp corners, this will make the seam effectively invisible.

To be precise, this will try to choose a concave non-overhang vertex so that the seam is hidden inside of the concave angle. If no concave non-overhang vertices are available, it will choose a convex non-overhang vertex. If none are available, it will choose a non-overhang vertex. The choice among the candidates is operated so that the start point is the nearest to the previous extruder position. So this option will optimize for short travels.

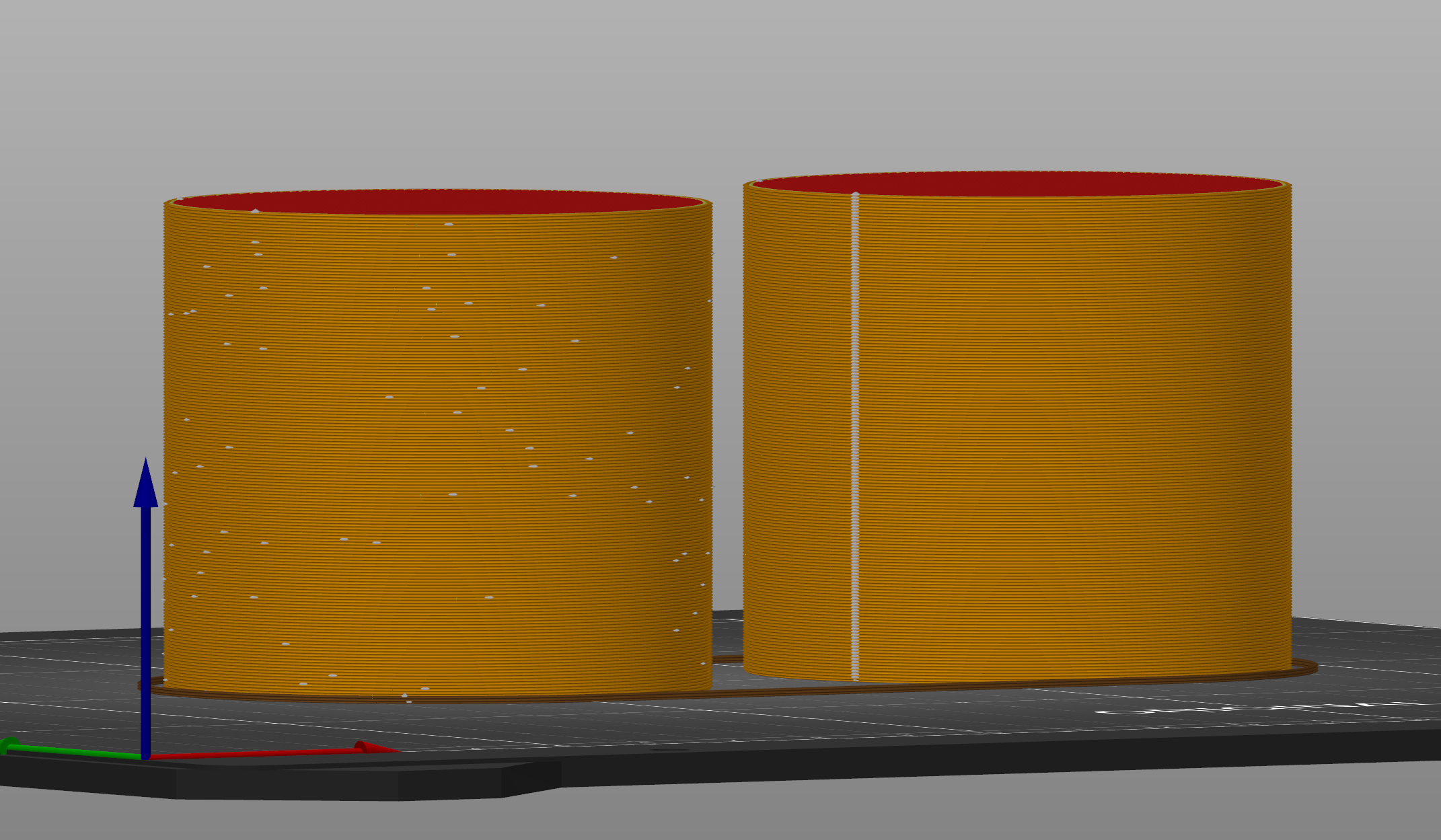

Aligned

This will use the same logic as the Nearest for finding the candidates, but it will choose the one that is nearest to the start point of the previous layer. This will ensure the seam is mostly aligned throughout the whole object.

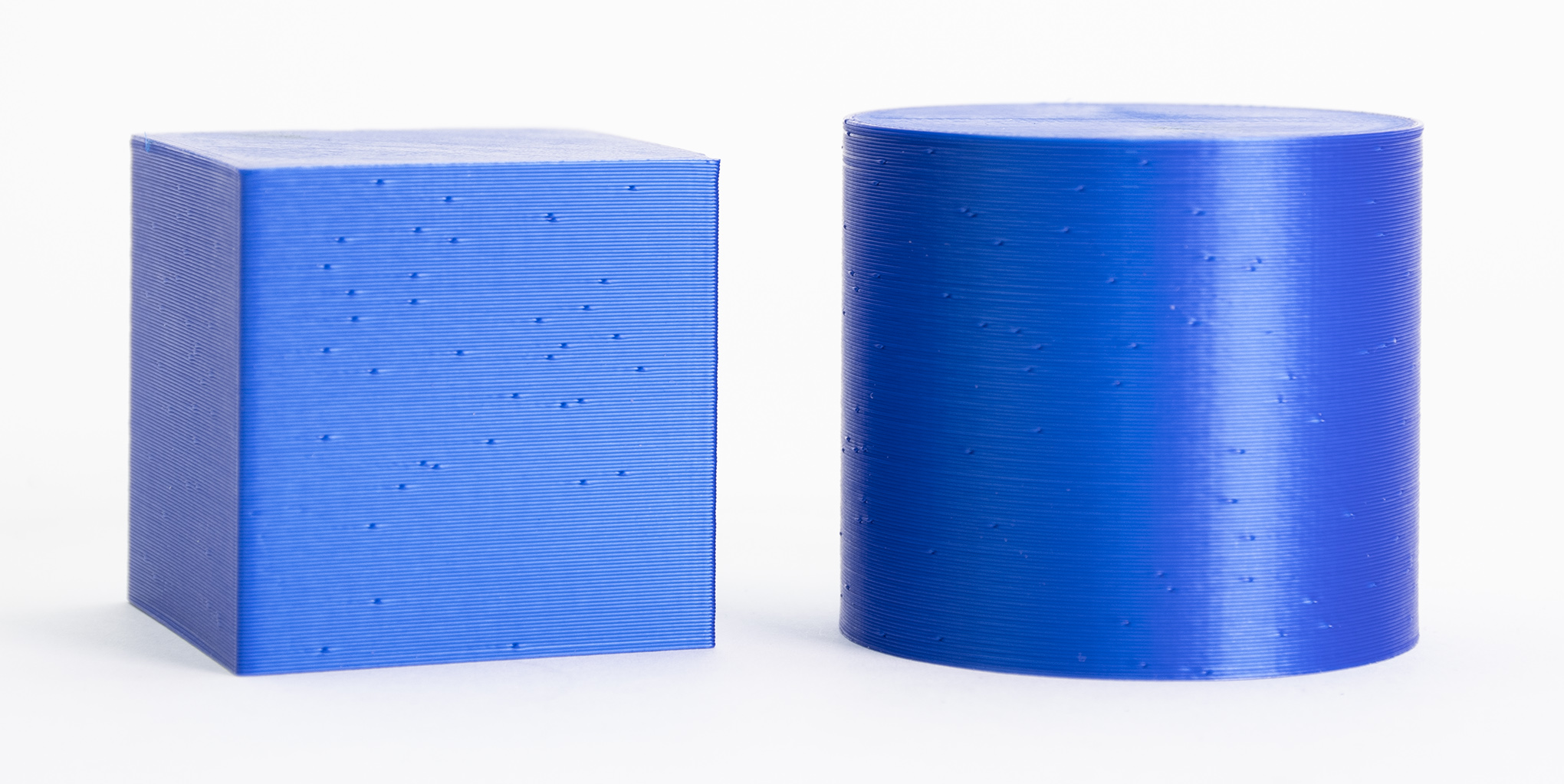

Random

This will choose a different point for each layer, making the seam less noticeable at the cost of a less smooth surface (small zits scattered across the surface).

It makes little sense to use Random seam position on models with corners/sharp edges, it's much better to use Nearest or Aligned in such cases. On the other hand, when printing cylindrical shapes without any sharp edges, the Random seam position is a viable option.

Rear

The Rear position works similarly to Aligned, but it will try to position the seam close to max Y (rear of the print bed). It still tries to avoid overhangs and tries to put the seams in the corners.

Seam gap distance

The distance between the endpoints of a closed loop perimeter. Positive values will shorten and interrupt the loop slightly to reduce the seam. Negative values will extend the loop, causing the endpoints to overlap slightly. When percents are used, the distance is derived from the nozzle diameter. Set to zero to disable this feature.

Staggered inner seams

This option causes the inner seams to be shifted backward based on their depth, forming a zigzag pattern.

Scarf joint placement

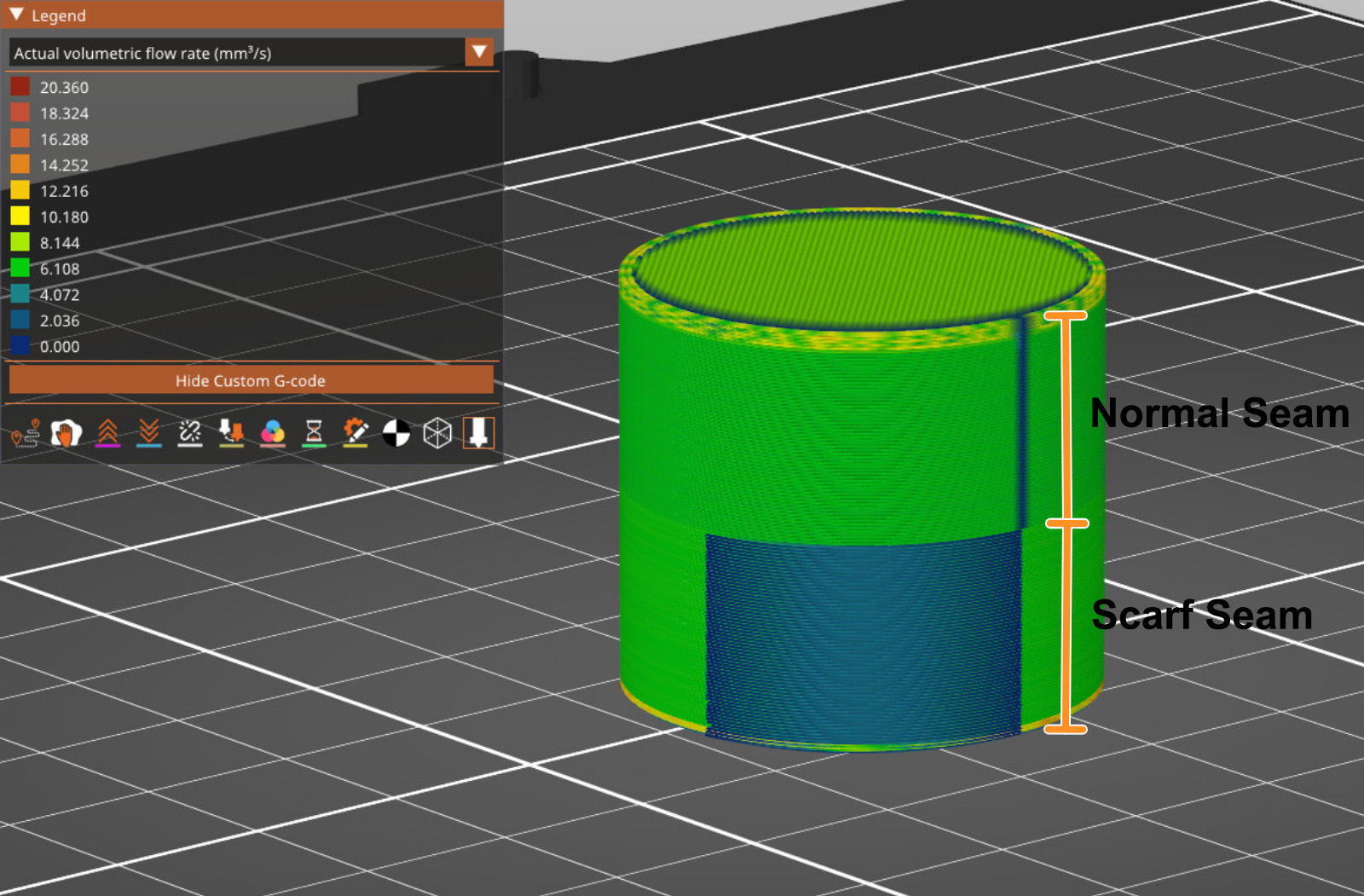

The Scarf seams overlap extrusions at the end and start of the perimeter loop, hiding visible seams on smooth perimeters. You can visualize the seams in the printer preview using the Volumetric flow rate (mm³/s) or Actual volumetric flow rate (mm³/s) options in the preview legend.

Nowhere

The function is disabled.

Contour

The scarf seams will only be applied to the contour of the object.

Everywhere

The scarf seams will be applied on all object seams.

Scarf joint only on smooth perimeters

This is the standard option in case the Scarf joint is enabled. The scarf joint is not applied on non smooth surfaces as the seam can be hidden on curves and corners of the object. If this option is unchecked, the scarf joint will also be applied on these non smooth surfaces.

Scarf start height

The height of the scarf joint, specified as a fraction of the current layer.

Scarf joint around entire perimeter

Extend the scarf around the entire perimeter.

Scarf joint length

Change the length of the scarf joint

Max scarf joint segment length

Maximal length of any scarf joint segment.

Scarf joint on inner perimeters

The scarf seams are usually only added to external perimeters. Checking this option adds the scarf seam on the inner perimeters.

How to reduce the visibility of the seam

With the FFF/FDM technology, it is not possible to eliminate the seam. It will always be somewhat visible. However, with well-tuned settings, it shouldn't be too noticeable.

Settings that affect the visibility of the seam are Linear Advance and Extrusion multiplier calibration. Original Prusa profiles have these settings already tuned, but if you're fine-tuning a custom profile, you can try lowering the extrusion multiplier and calibrating the linear advance value to lower the visibility of the seam.

You can use the Vase mode to avoid the seam, but then you'll be limited to using only one perimeter and no infill.