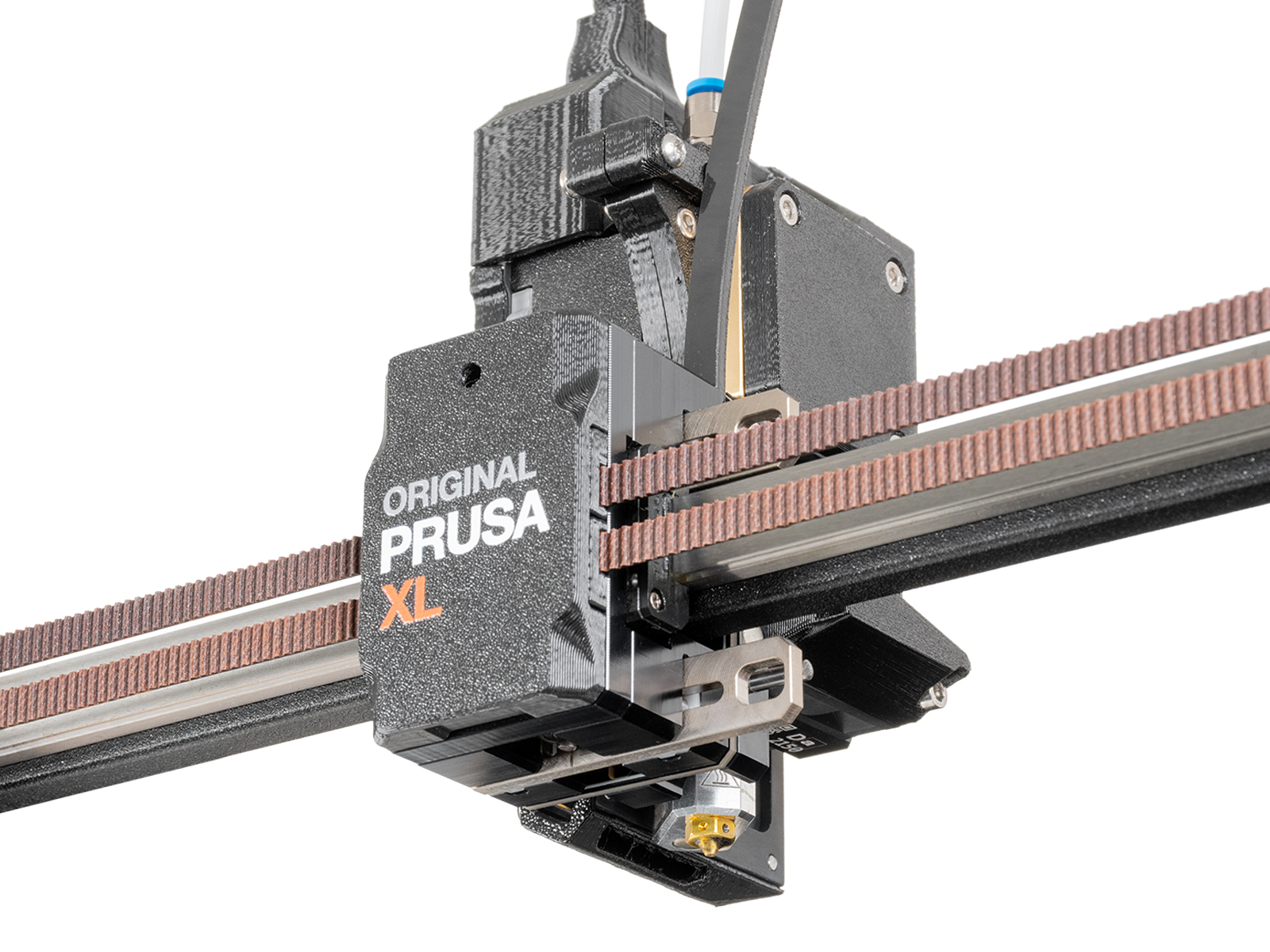

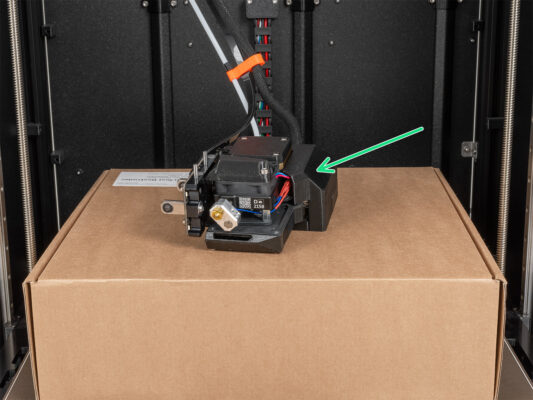

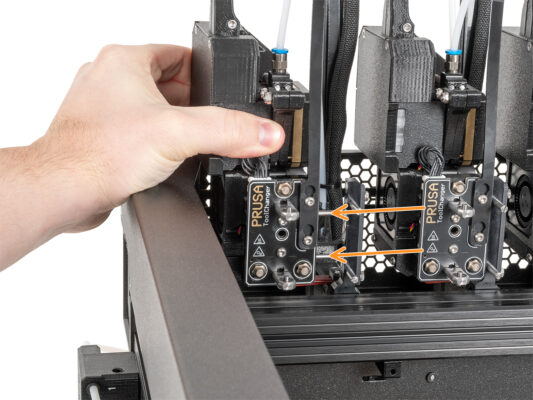

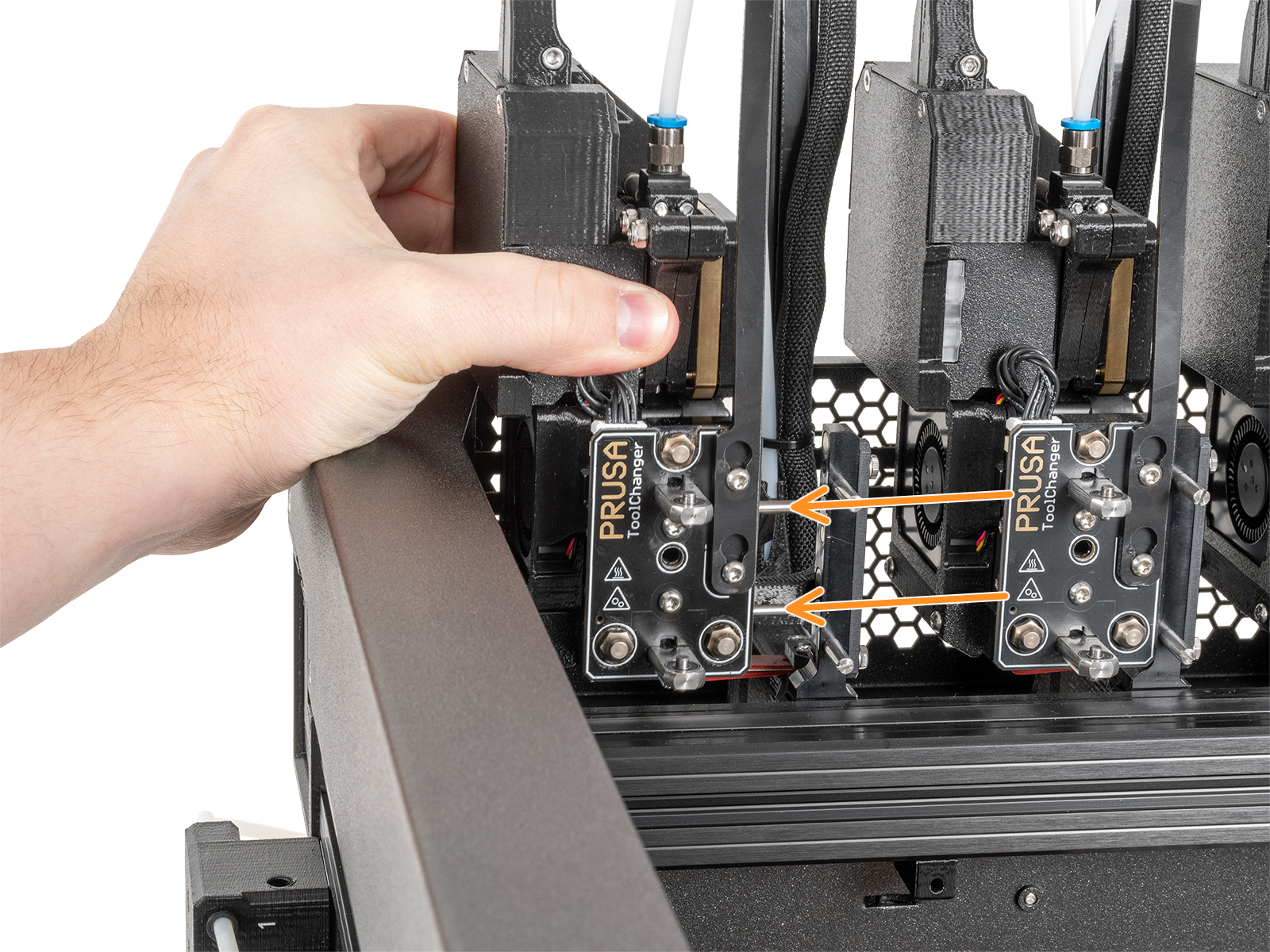

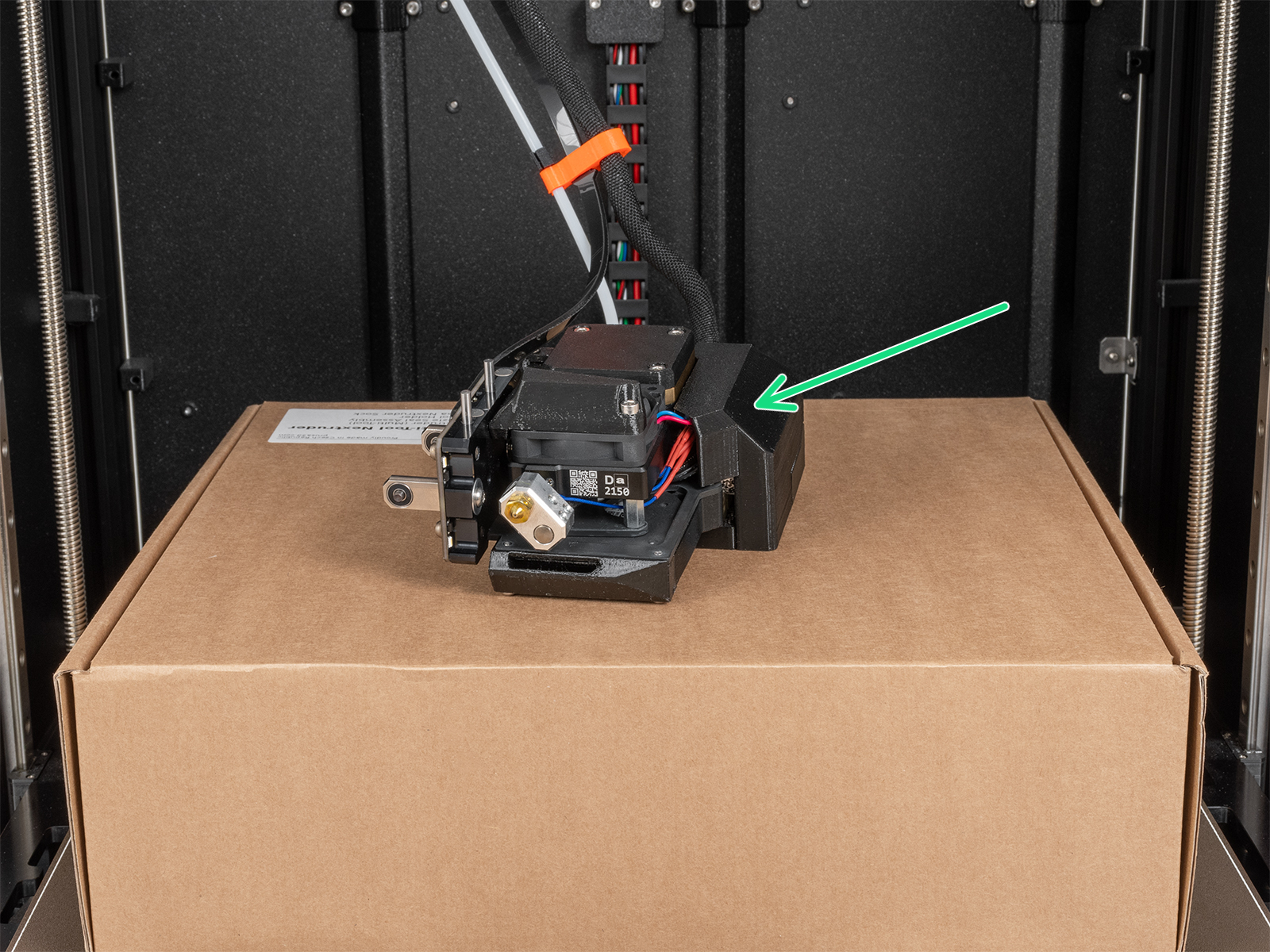

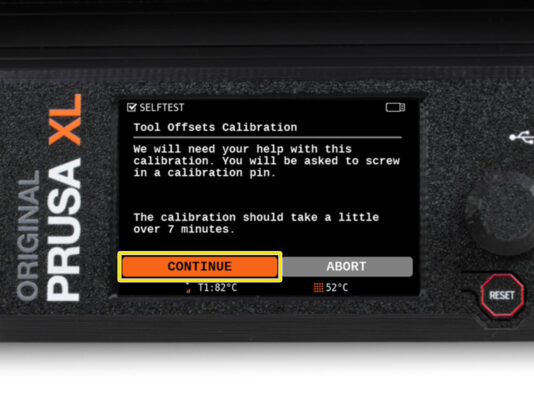

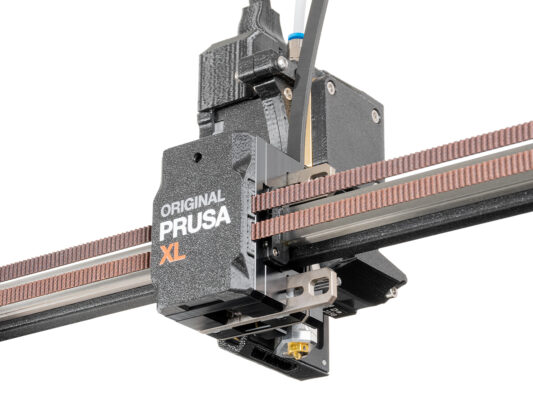

⬢This guide will take you through the installation of the Nextruder V6 Nozzle Adapter on the Original Prusa XL Multi-tool.

For the installation of the Nextruder V6 Nozzle Adapter on the Original Prusa XL (Single-tool) go to the dedicated guide: How to replace the Prusa Nozzle (XL Single-Tool)

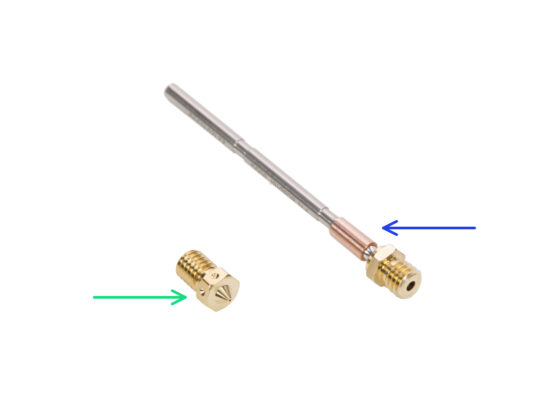

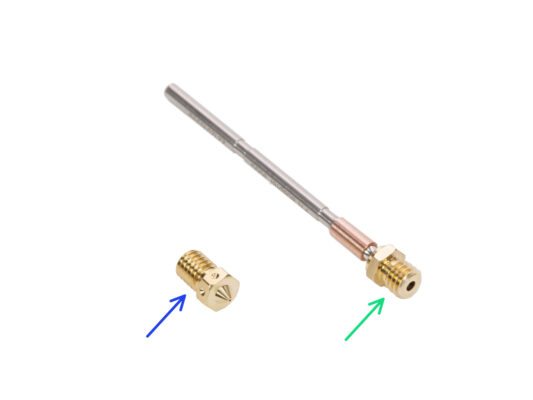

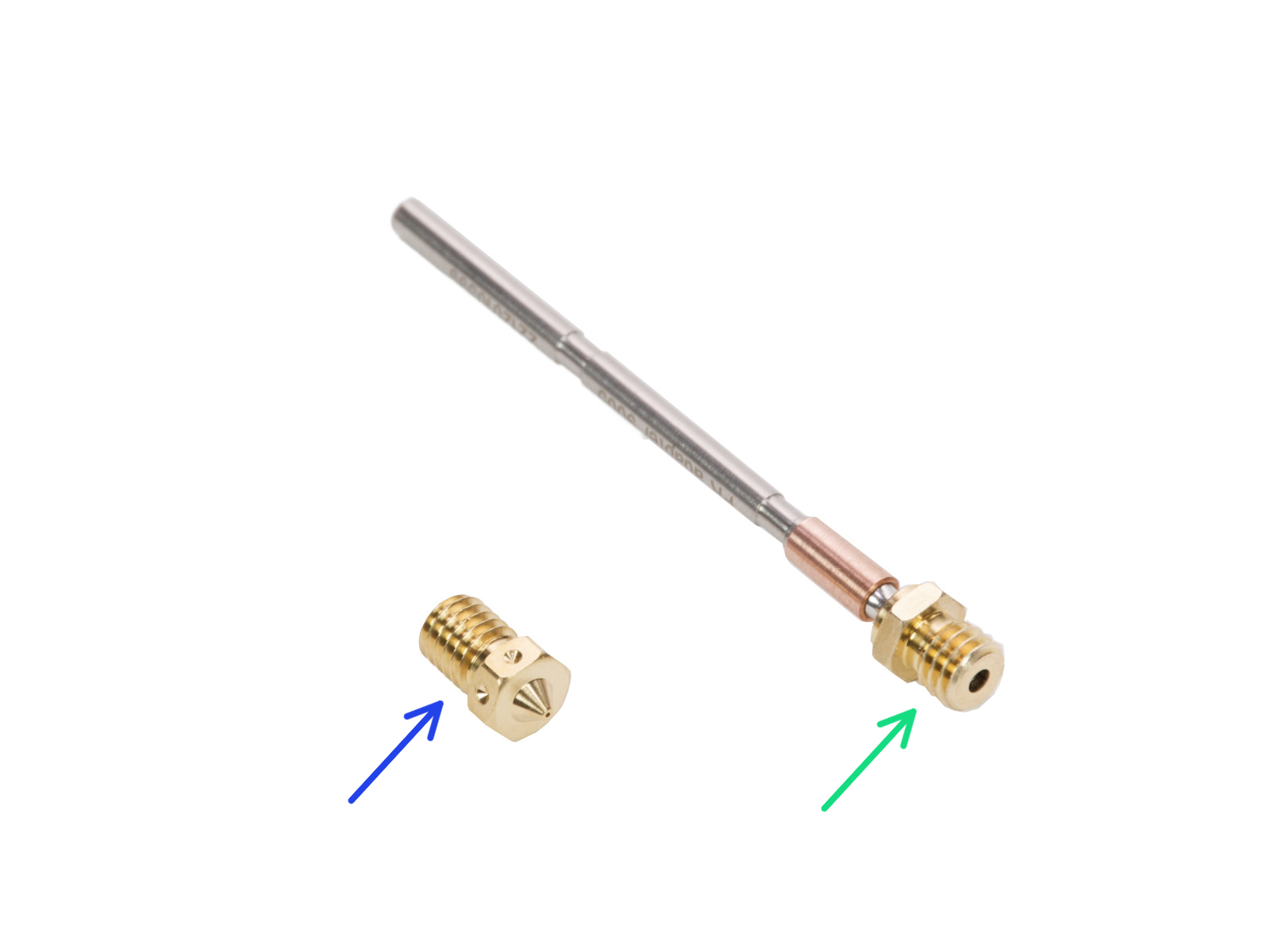

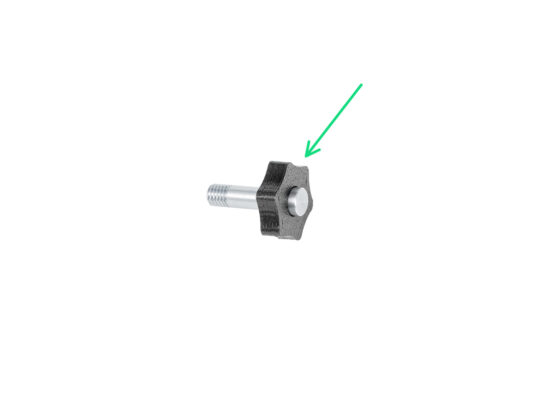

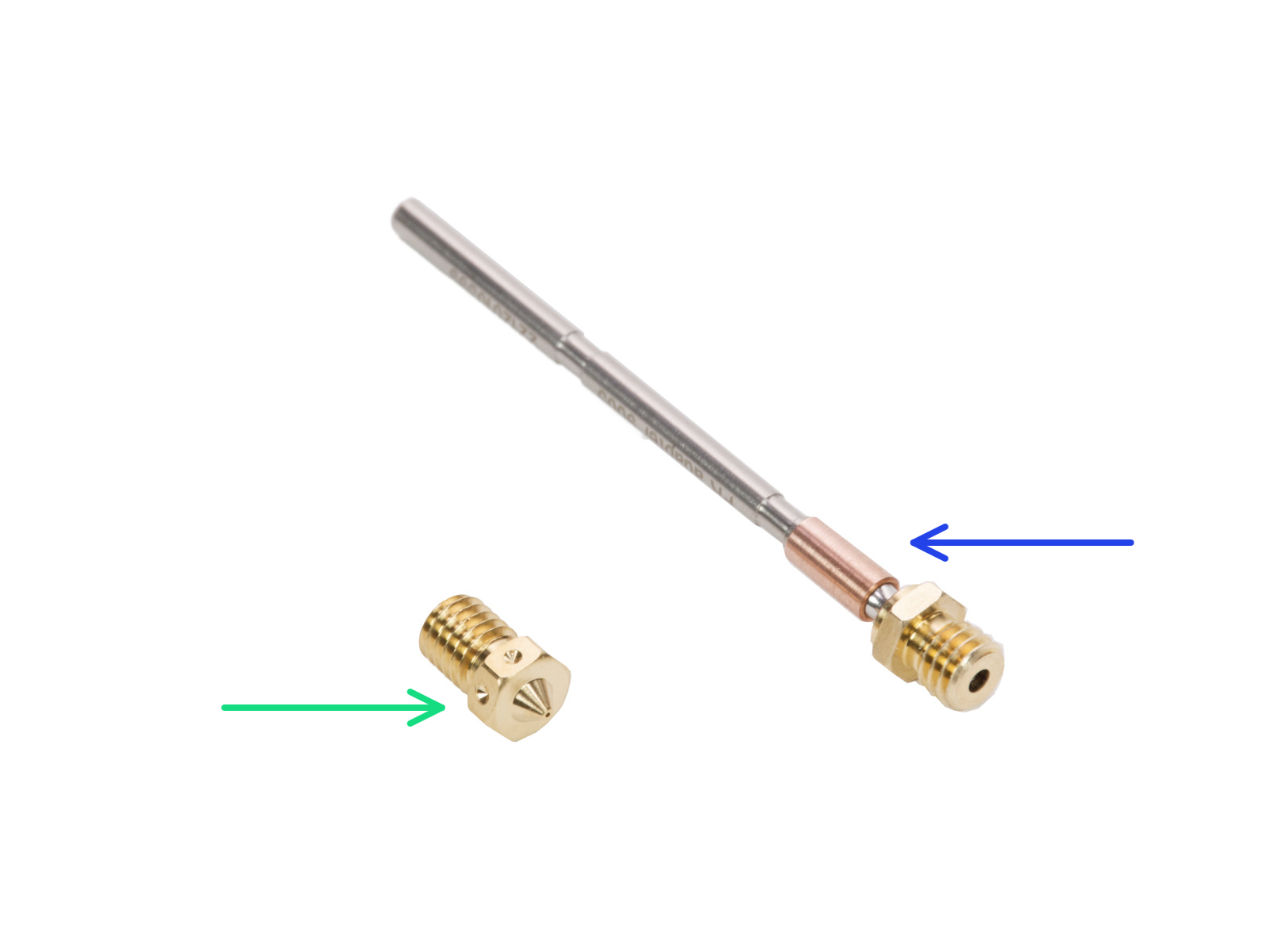

⬢V6 nozzle is available in our eshop prusa3d.com.

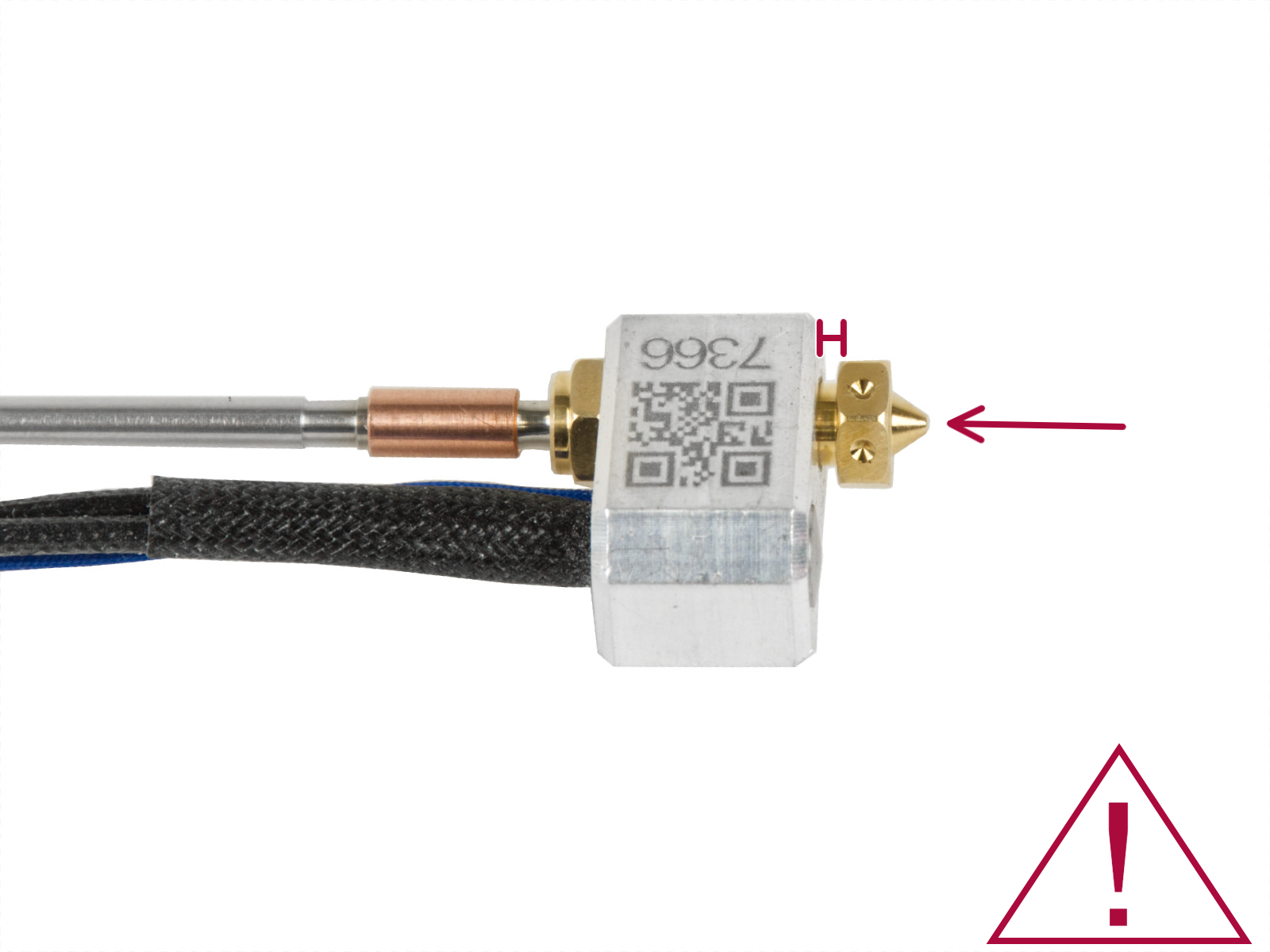

The following instructions are compatible with all V6 nozzle diameters.

⬢Nextruder V6 Nozzle Adapter is shipped with the Original Prusa XL. And it is available in our eshop prusa3d.com.

Note that you have to be logged in to have access to the spare parts section.