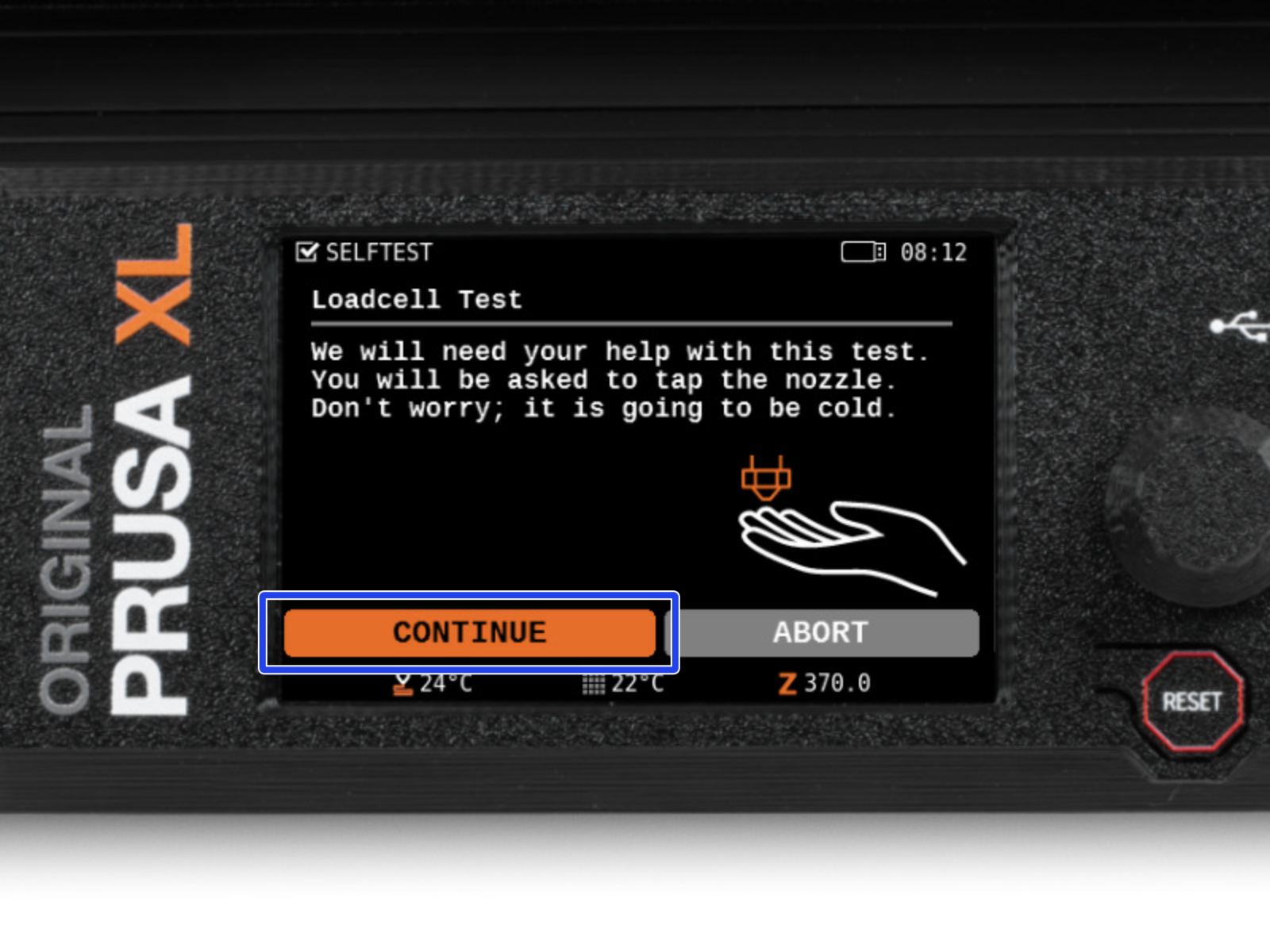

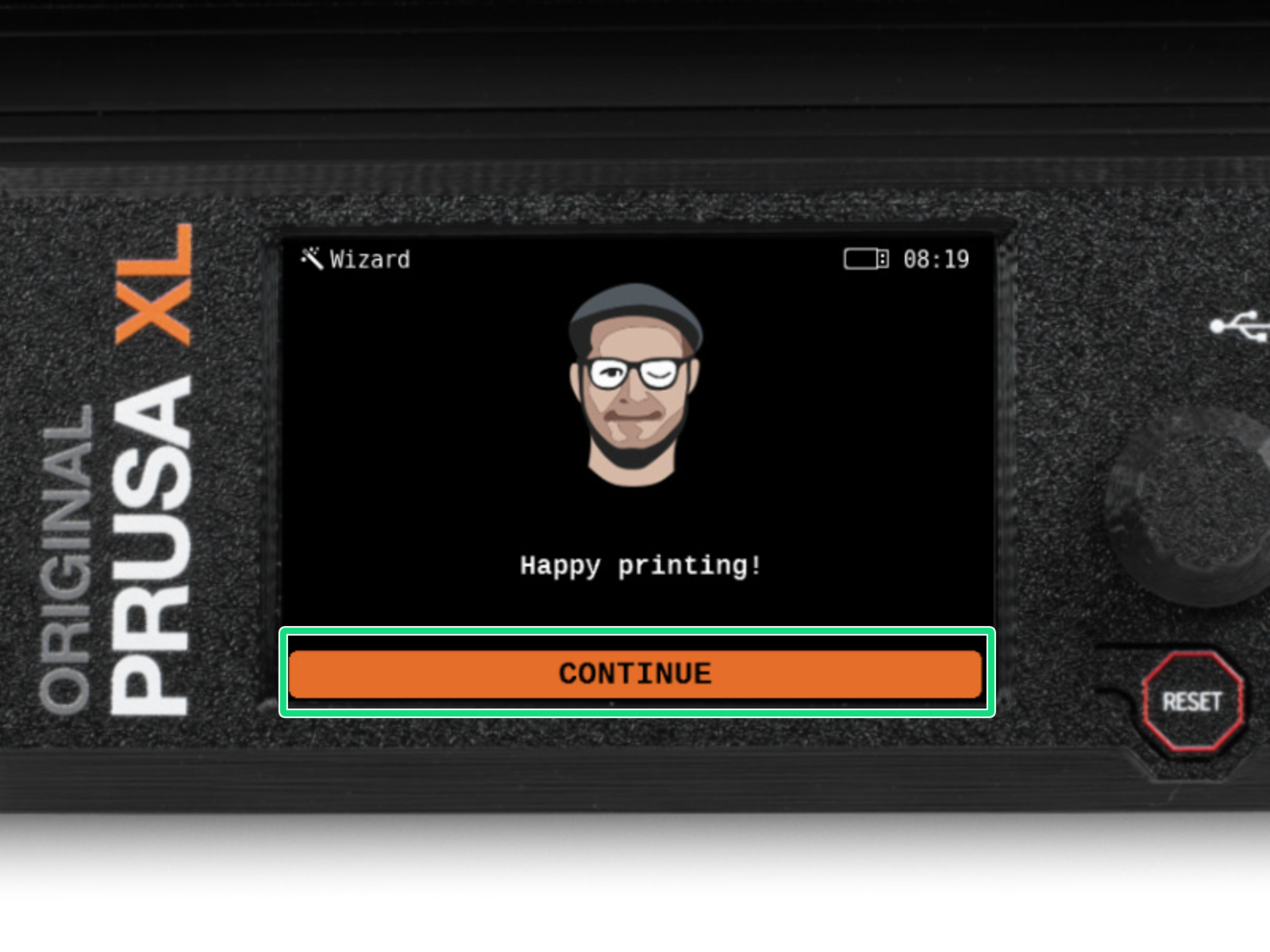

This chapter shows a brief description of the wizard. Please note that the screenshots are illustrative and might differ from those in the firmware.

Make sure you are running Firmware 5.1.2 or newer

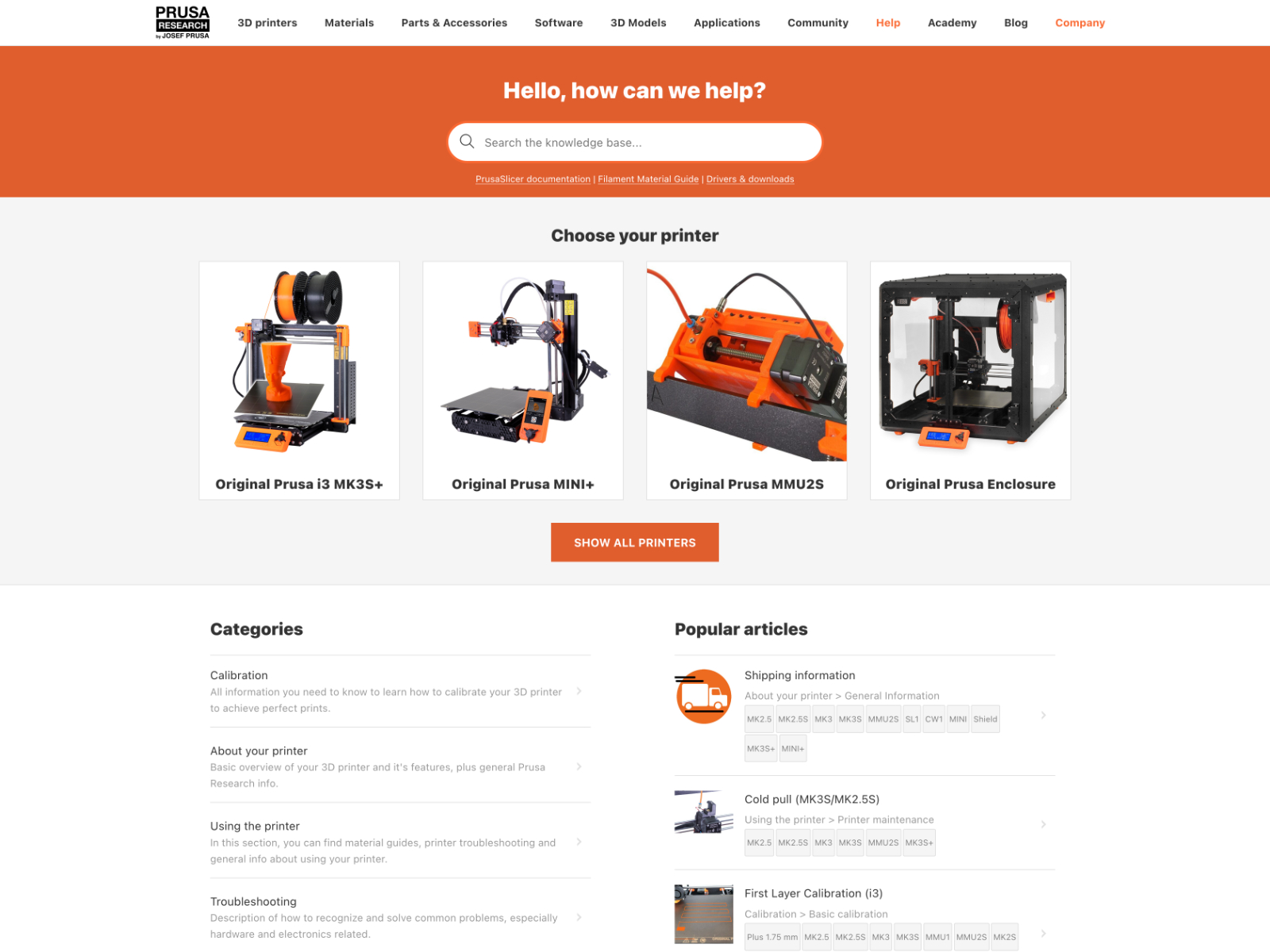

If you have a question about something that isn't covered here, check out our additional resources.

And if that doesn't do the trick, you can send an inquiry to [email protected] or through the button below.