What happened?

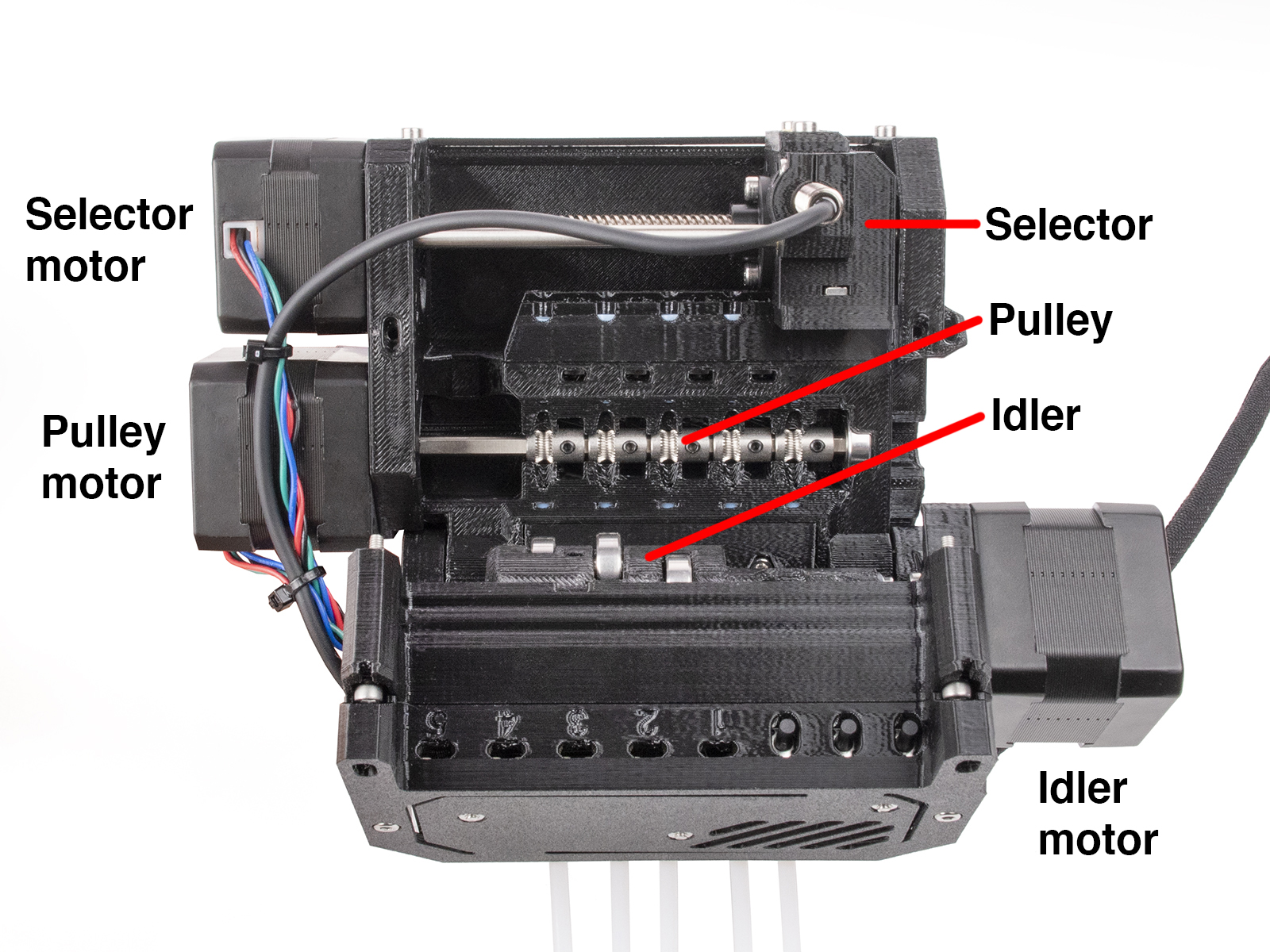

Before it can align with any of the filament positions, the Idler inside the MMU unit needs to be “homed” to determine its position. First, the Idler moves to one end of the travel (endstop). Then, it moves to the other endstop, while measuring the angle between the end stops. The idler homes after the unit starts up has been reset or after another error occurred.

In case it can’t find the first homing endstop or the distance between the two endstops differs from the expected value, the printer will show an error.

Distance between the Idler endstops: 225 degrees

Allowed deviation: 10 degrees

How to fix it?

The issue is usually mechanical. If you get this error, check the following items:

- Verify there is no debris around the Idler and that it can move freely.

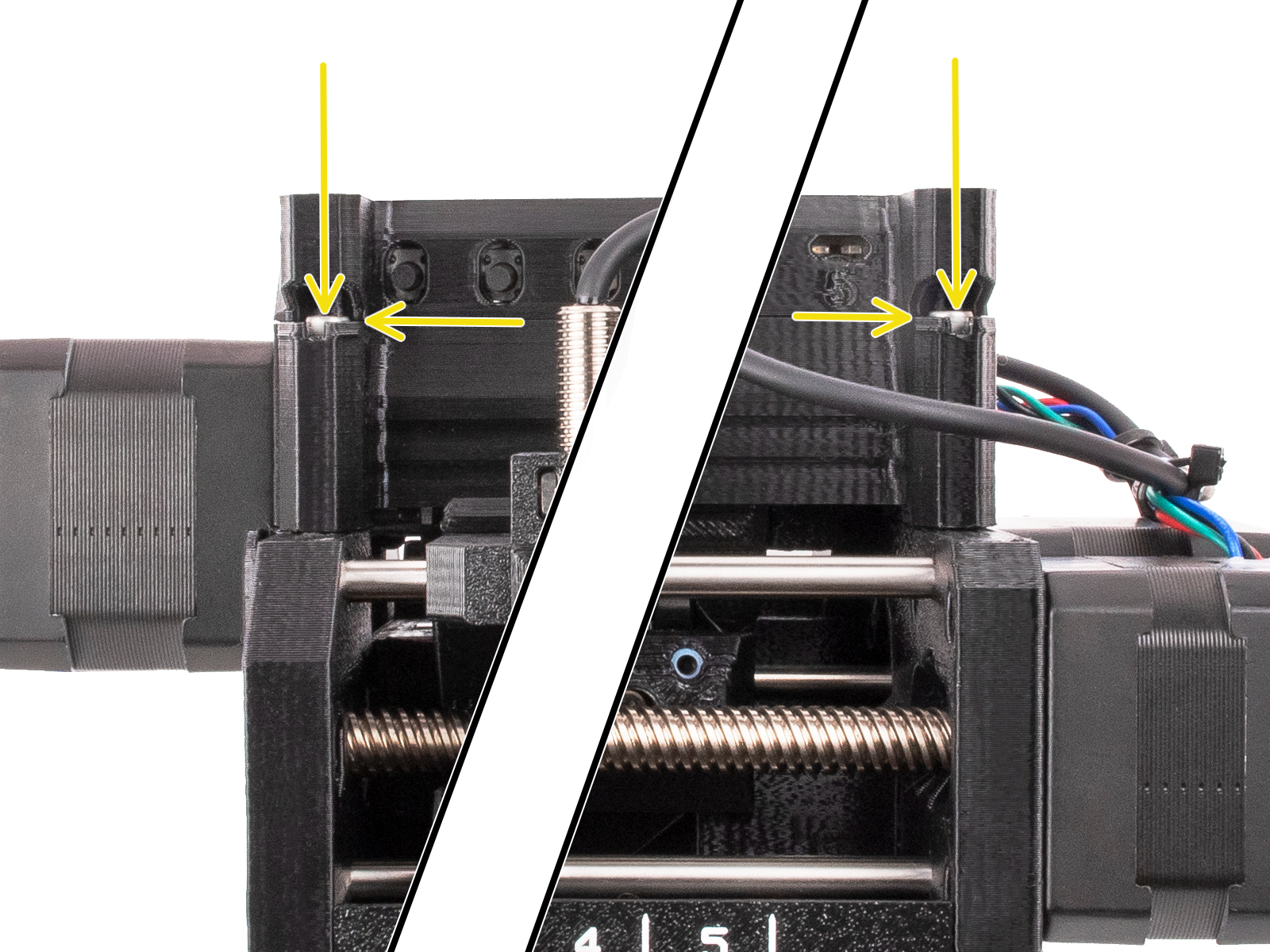

- Release the idler tension screws slightly. If it is too tight, it will disable the Idler from moving freely.

|  |

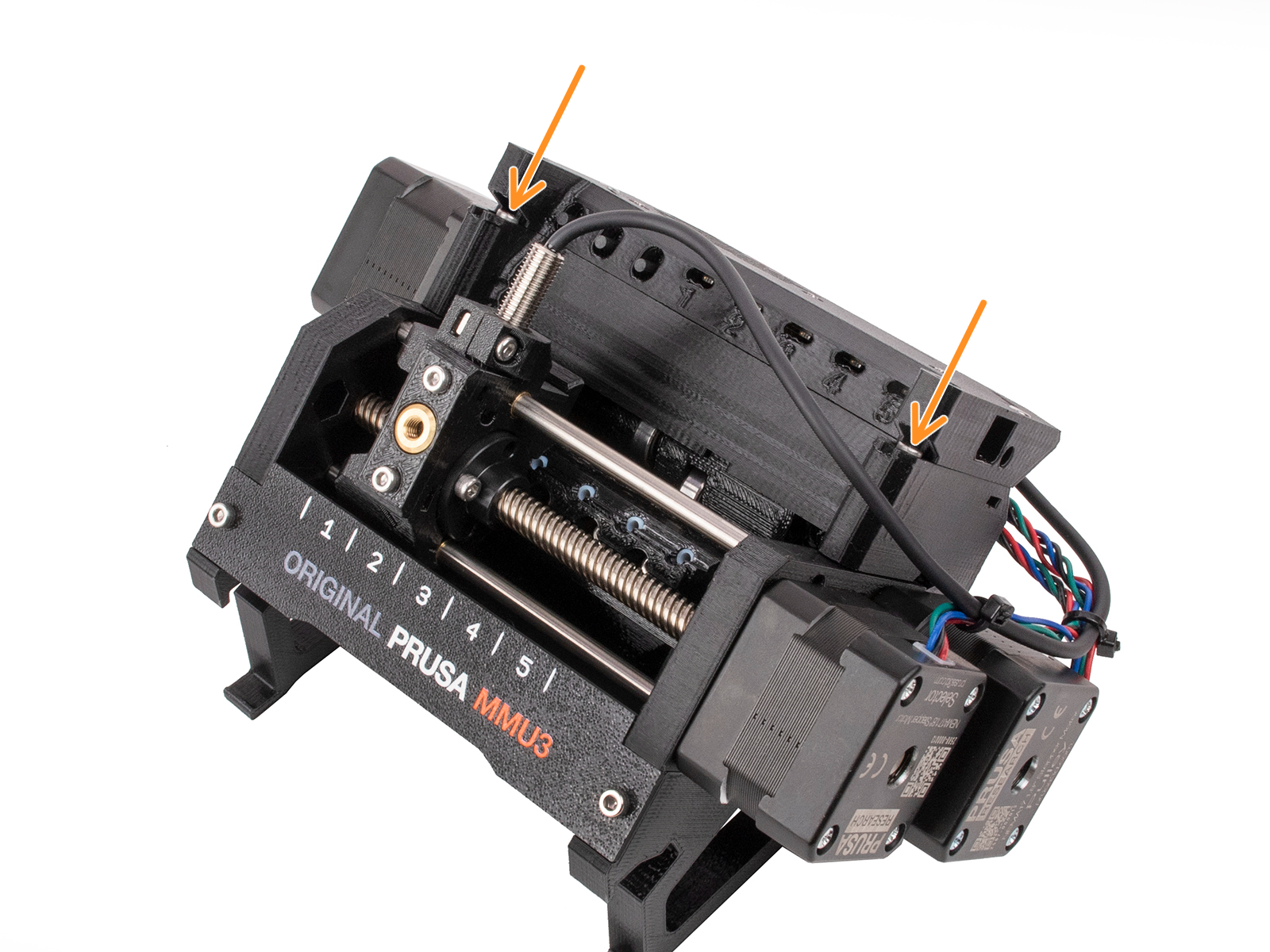

- Verify is the Idler Coupler is attached properly. Check both grub screws on the Idler Coupler are tightened and that one of the screws is facing the flat part of the motor shaft. Make sure the Idler doesn’t push against the Idler body so that it can rotate freely.

|  |

- Especially the first time you are running the MMU, check that the motors are connected in the correct order.

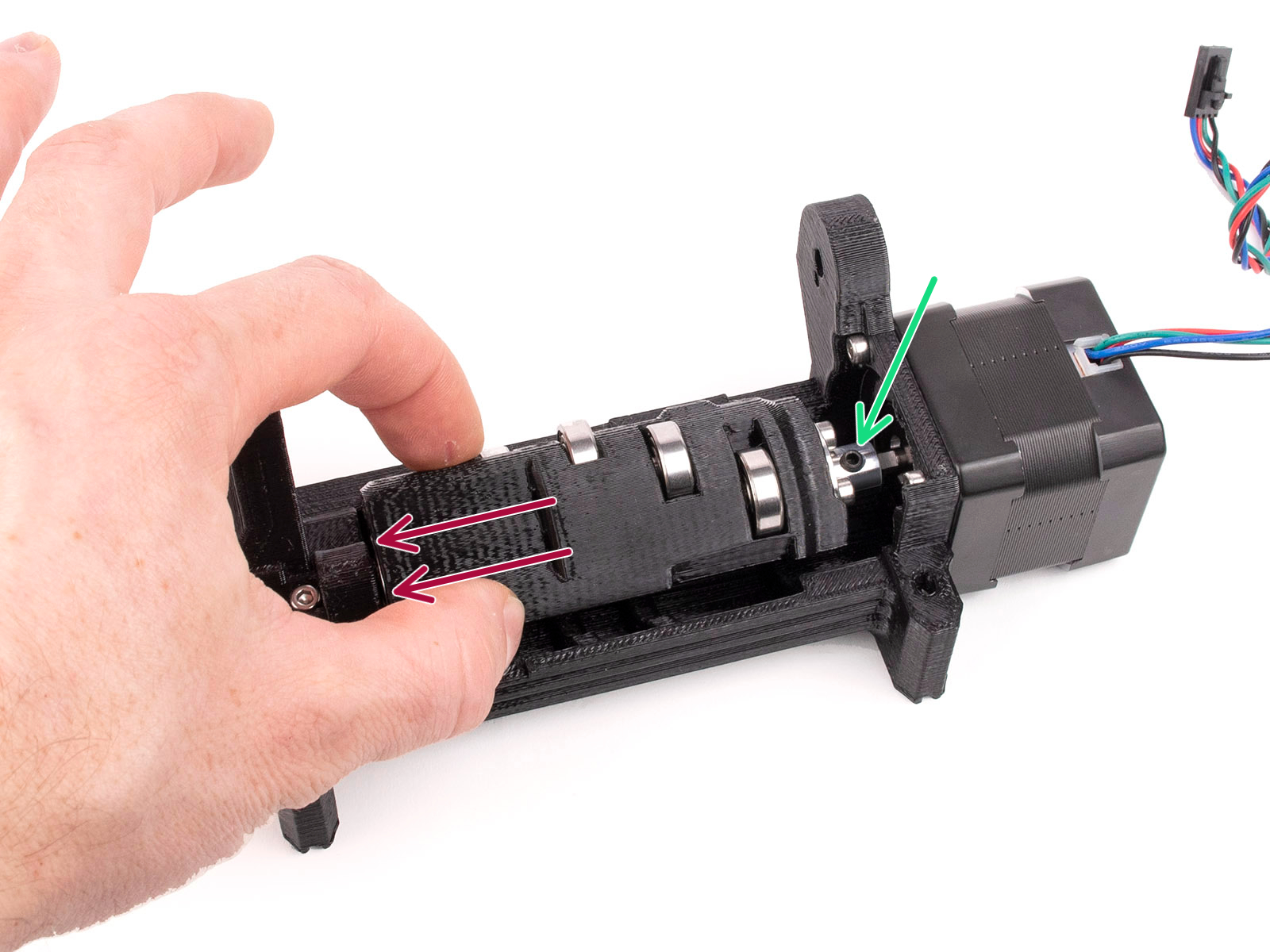

- Verify all the bearings can move freely and that the center shaft at the end is inserted into the Idler properly.

- In case you are using the older MMU2S unit, check the MMU idler unable to move freely article.

- In some specific cases, the unit might not be able to find the first homing endstop. This can occur, for example, when using a non-standard motor for the Idler axis. Adjusting the stall guard thresholds might help.

Adjusting the Idler Stallguard threshold:

When using an unsupported, third-party hardware or a rare differently-sized version of the Idler motor from the MMU1 to MMU2 upgrade kits or the early batch of MMU2, later upgraded to MMU2S and finally to MMU3, you might need to tweak the sensitivity threshold of the StallGuard feature (Idler_sg_thrs_R). The current MK3S+ printer firmware allows you to Tune the threshold to a value between 4 and 7, directly from the error screen. If none of the values in this range help, you may need to set it to a value outside this range.

Some of these specific units might need to set the Idler sensitivity to a higher number such as 10.

You can do so by running a specific G-code command: M708 A0x19 X10. (where X10 denotes threshold value 10.) After that you can reset the MMU with: M709 command. Note that the commands are case-sensitive.The command can be either run in a G-code file, or sent to the printer via USB connection, using a serial terminal app such as PuTTY.

For more info about the aforementioned commands, see the Registers MMU (MMU3) [進行中の翻訳] and the Prusa firmware-specific G-code commands [進行中の翻訳] articles.