The Input Shaper functionality on your Original Prusa MK4/S, MK3.9/S or MK3.5/S can be calibrated using an optional accelerometer. The accelerometer assembly consists of a small PCB enclosed in a printed cover, which connects to the printer. Please note that using the accelerometer requires partial disassembly of the printer.

|  |

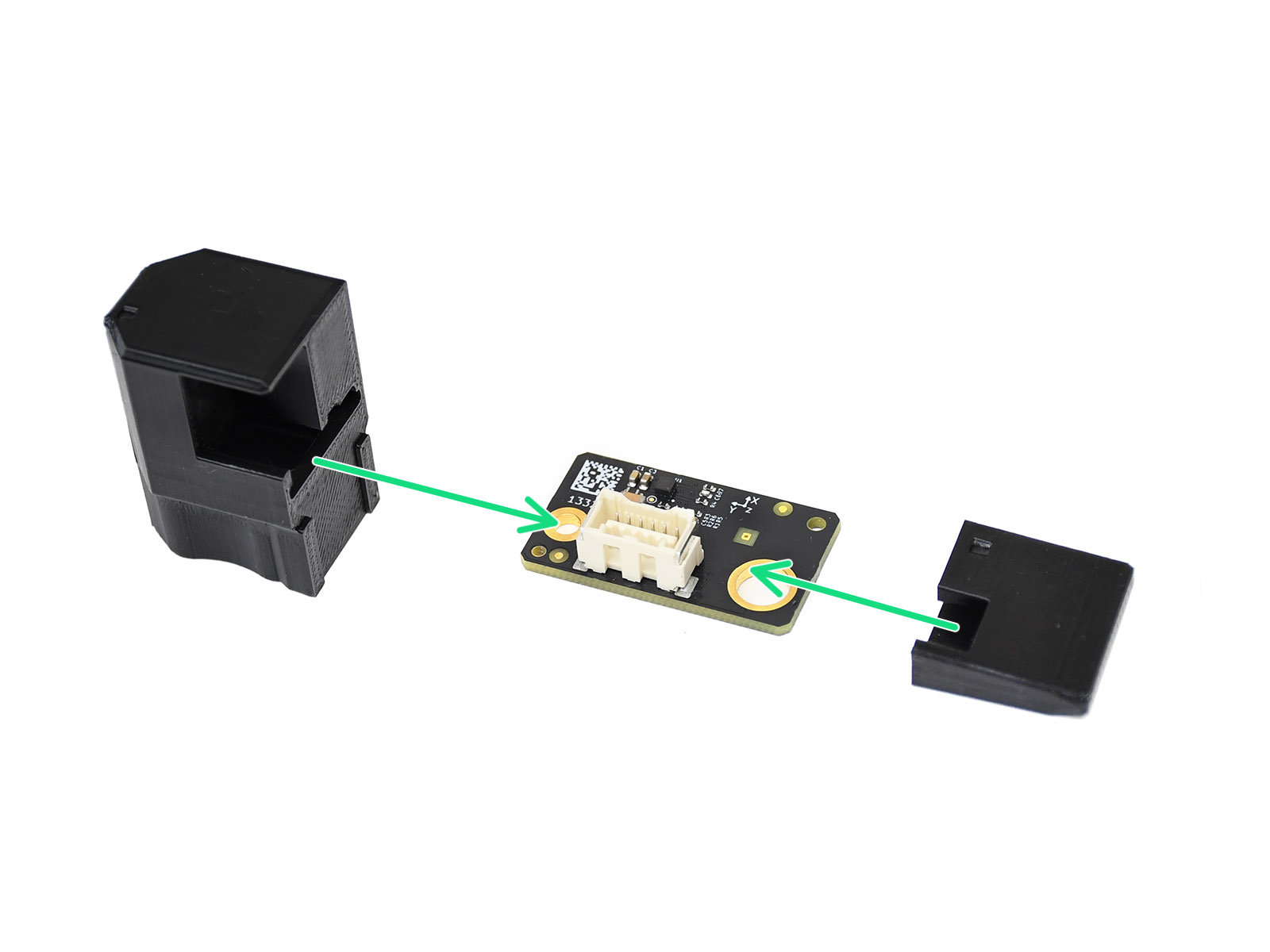

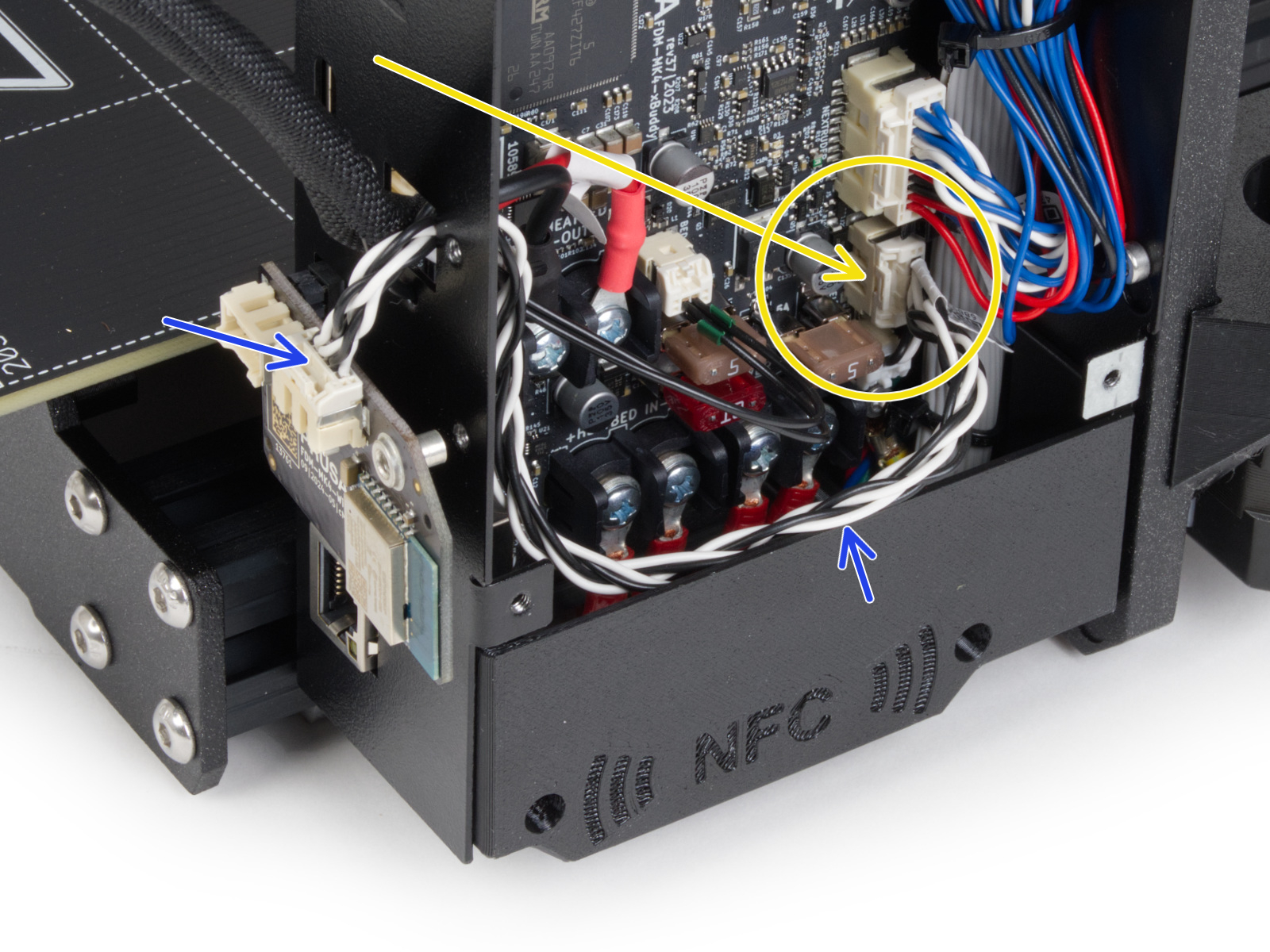

On MK4 and MK3.9, connect the cable into the accelerometer's PCB and attach the printed covers. (green arrows in the picture above) The accelerometer connects directly to the dedicated port on the xBuddy board. (yellow arrow in the picture below)

On MK4S and MK3.9S, assemble the accelerometer as in the picture above. The accelerometer connects into the dedicted port on the xBuddy board. (yellow arrow in the picture below)

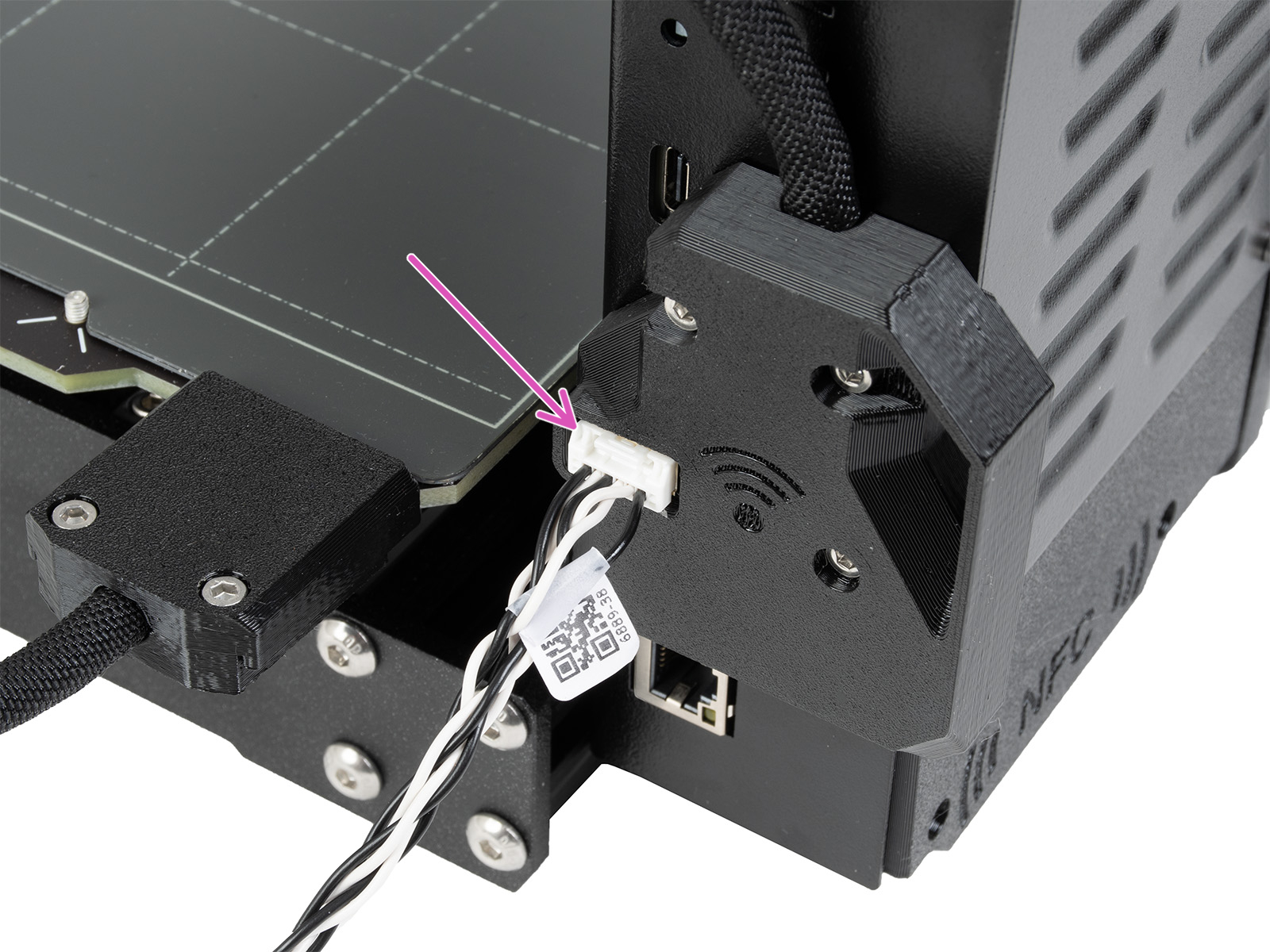

Alternatively, you can install a short jumper cable between the xBuddy (blue arrow) and the Wi-Fi module on the back of the printer. Then, you can connect the accelerometer into the connector on the back of the printer. (pink arrow).

|  |

Accelerometer connection on MK4S and MK3.9S

For MK3.5 or MK3.5S, please visit the dedicated guide.

The accelerometer is used to calibrate the input shaper parameters. You can launch the calibration from the LCD Menu -> Settings -> Input Shaper -> Calibration.

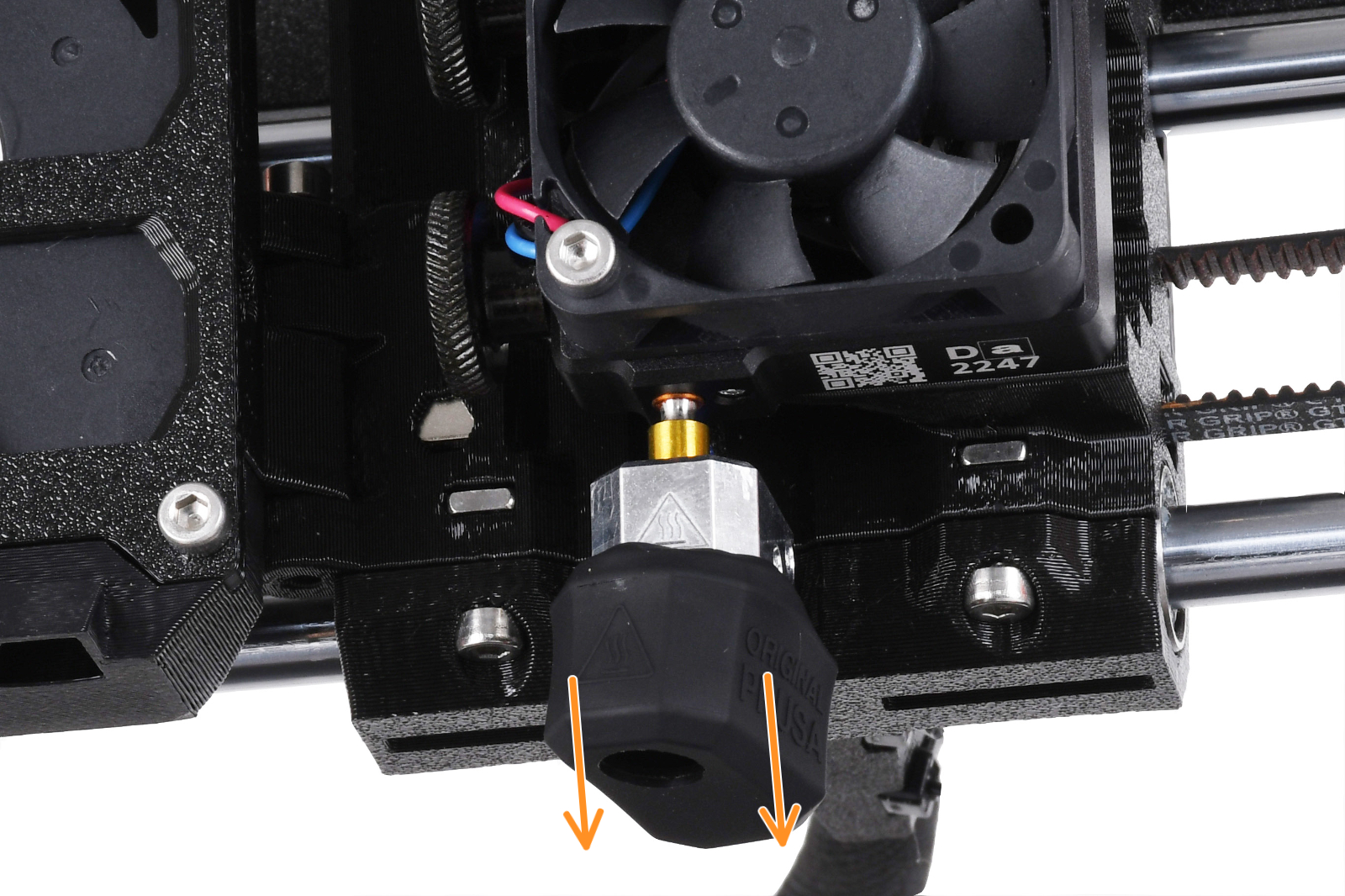

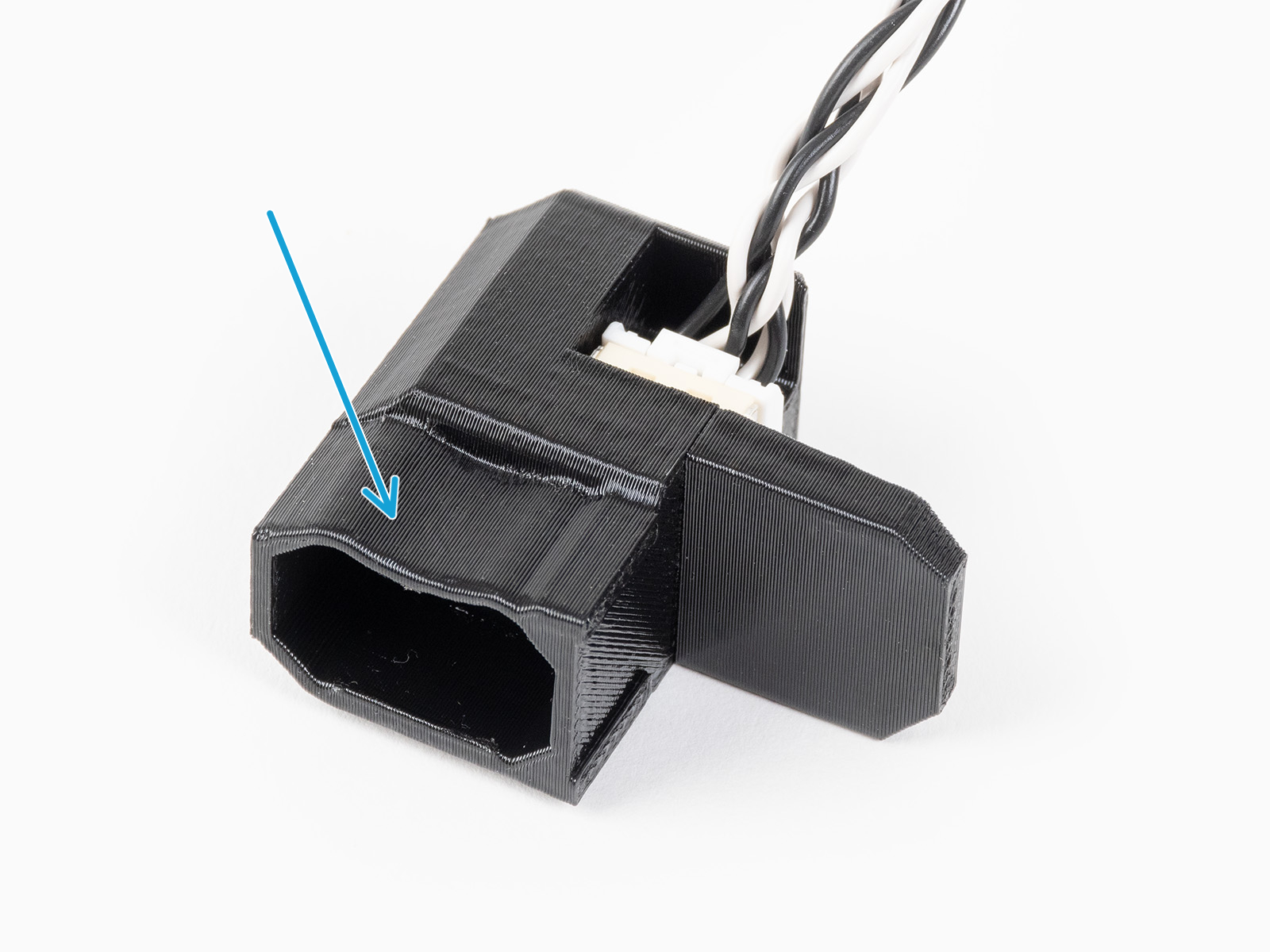

On MK3.9 or MK4, open the fan-door completely before the procedure. Remove the silicone sock, if installed. Identify the part of the accelerometer that is in the shape of the heater block.

|  |

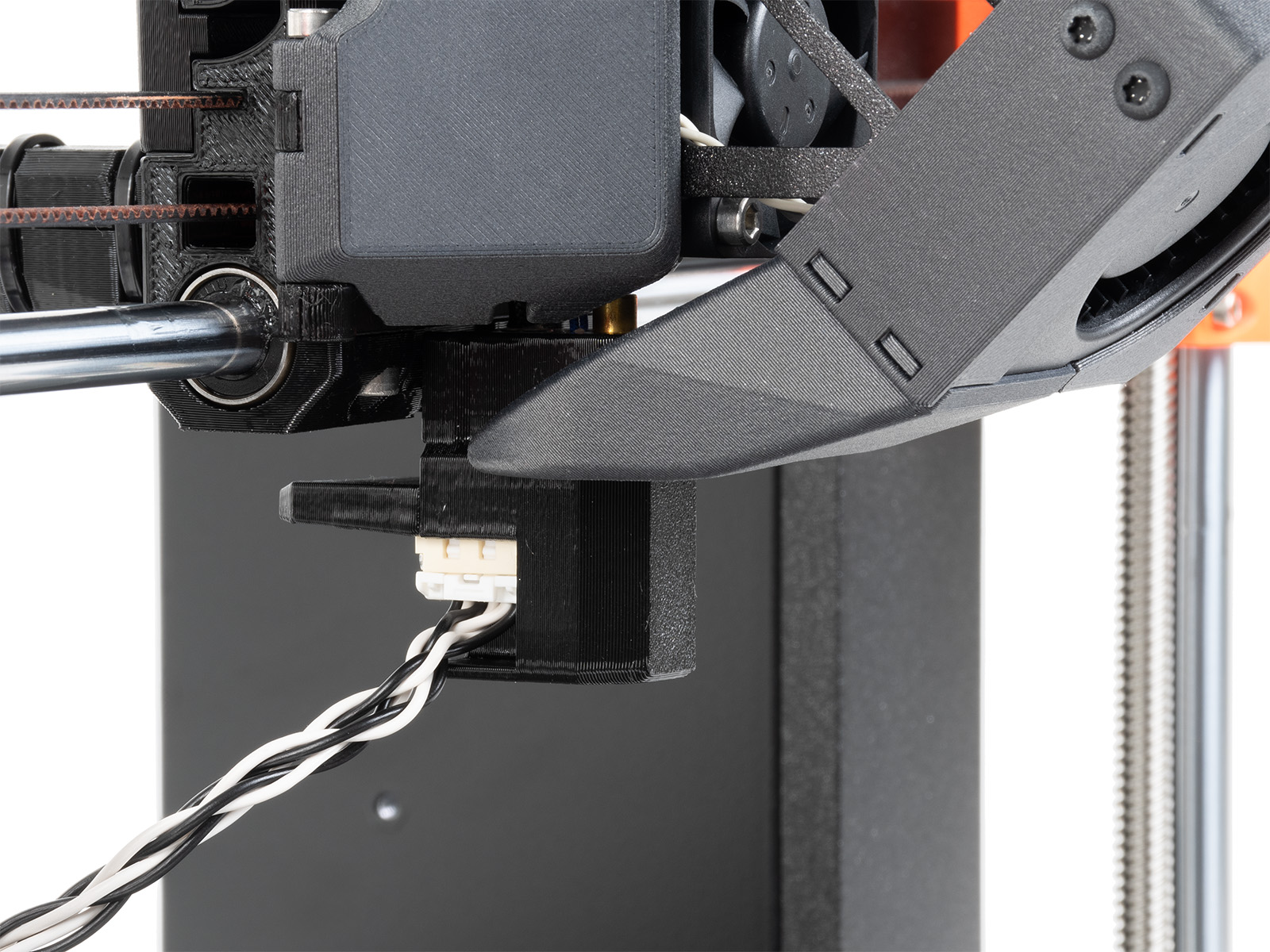

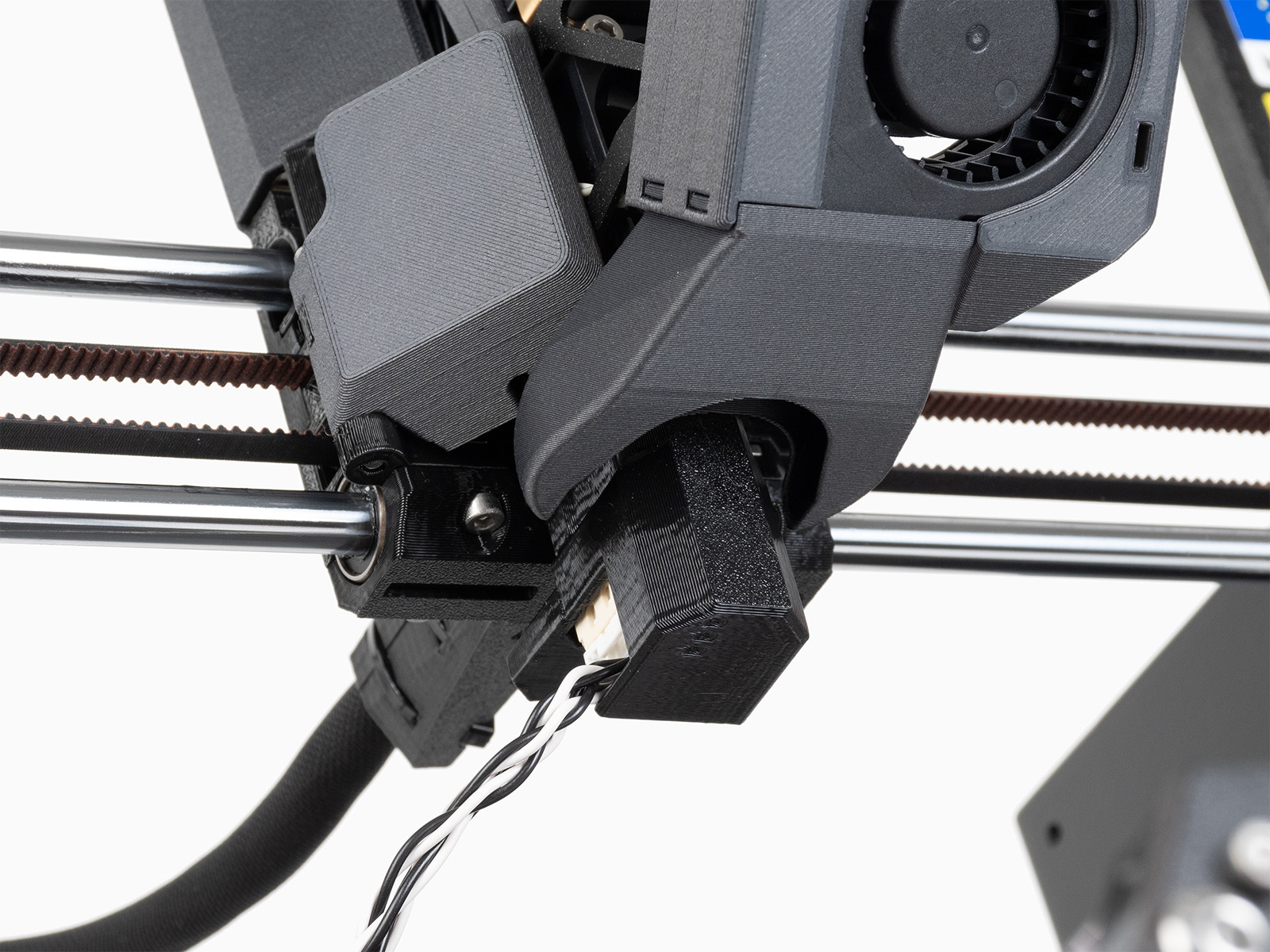

Fit the accelerometer to the heater block, by pushing it from the bottom of the hotend. If there is any resistance, do not attempt to push the accelerometer harder, as excessive force might bend the heatbreak.

|  |

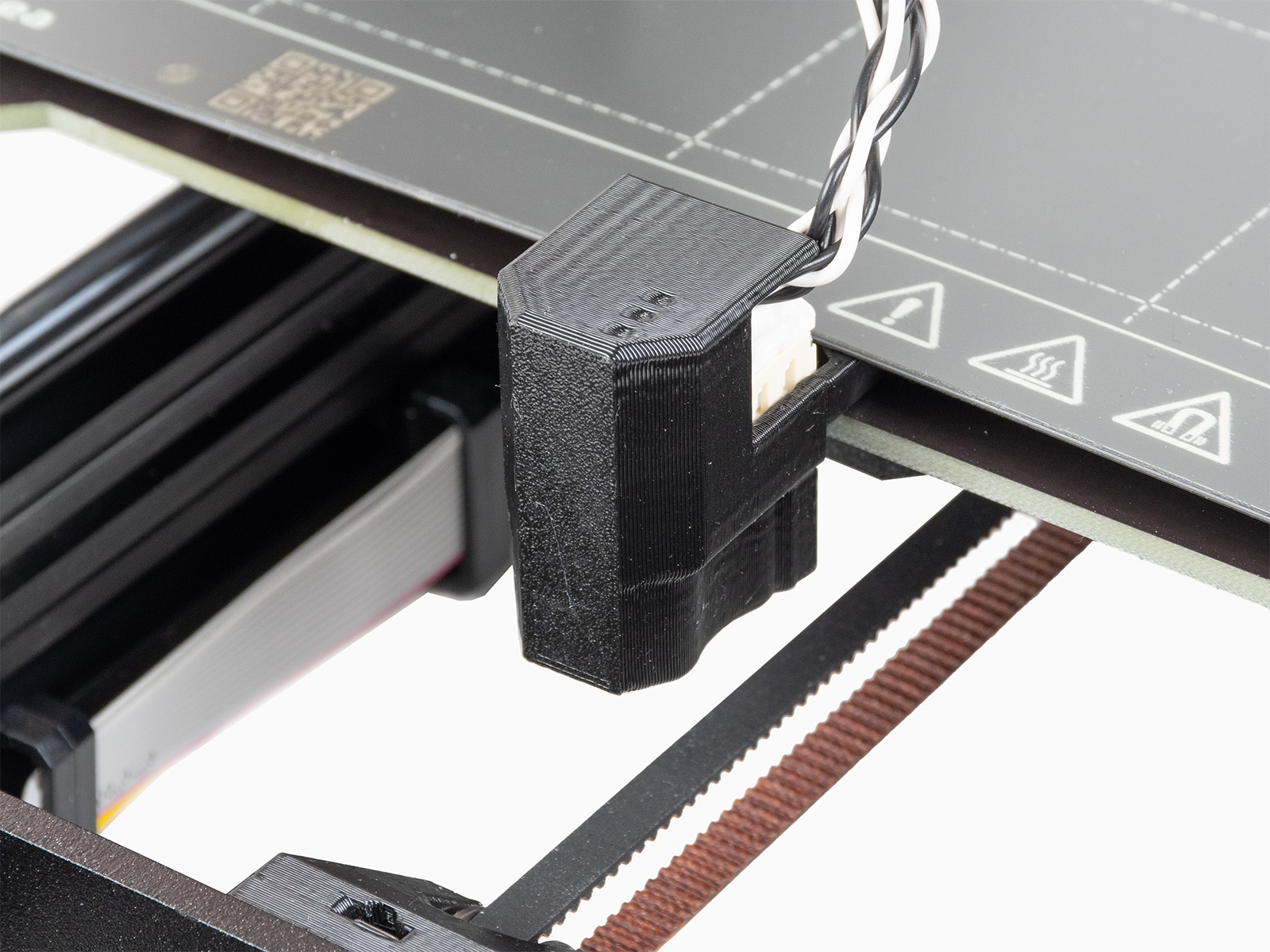

Identify the part of the accelerometer that protrudes from the rest. On the front side of the Y-axis, place the protrusion between the steel sheet and the heatbed.

|  |

The results shown on the printer's display at the end of the calibration indicate the optimal input shaping type and frequency found with the calibration.