Basic info

Description

PVB (Polyvinyl butyral) has similar print settings to PLA, mechanical properties are comparable with CPE or low-tier PETG. Thanks to its translucency and IPA smoothing, it is an ideal choice when you want to make design objects, such as unconventional vases, jewellery, lamp shades and similar objects. The most ideal are models that require partially transparent surface. It’s recommended to tweak print settings, especially layer height, number of perimeters and infill density. We recommend printing with large nozzle diameter and spiral vase mode.

PVB is not suitable for printing mechanical parts. Its dimensional stability is great, tenacity and tensile strength is comparable to CPE (and low-tier PETG) but temperature resistance is similar to PLA.

Since it's an easy-to-print material (similar to PLA), PVB is a great choice for both experienced and new 3D printer users that would like to try something new.

To compare supported material properties, see our material table.

|

Pros |

Cons |

|---|---|

|

✔ Print settings similar to PLA |

✖ Low layer-to-layer adhesion |

|

✔ Filament transparency |

✖ Hygroscopic filament (absorbs moisture) |

|

✔ Ideal for design parts, vases, lampshades, etc. |

✖ Higher price |

|

✔ IPA chemical smoothing | |

|

✔ Great surface adhesion | |

|

✔ Good tenacity (similar to CPE) | |

|

✔ Good tensile strength (similar to PETG) | |

|

✔ Low warping (lower than PLA) | |

|

✔ Good for using 0.8mm nozzle |

Best use

The best use of PVB is for printing transparent models, such as jewelry, vases, lampshades, etc.

Tips for successful printing

Do not use standard powder-coated TXT sheet

PVB adheres well to a clean smooth PEI sheet or satin TXT sheet. A powder-coated TXT sheet might not provide good adhesion.

Use the spiral vase mode

When printing transparent parts that require IPA smoothing, it’s good to print with a larger nozzle diameter (0.8mm) and with the spiral vase mode on. Printing with more perimeters will make layers visible even after IPA smoothing.

Chemical smoothing

Sample prints

|  |

| Lamp shades | Vases |

|  |

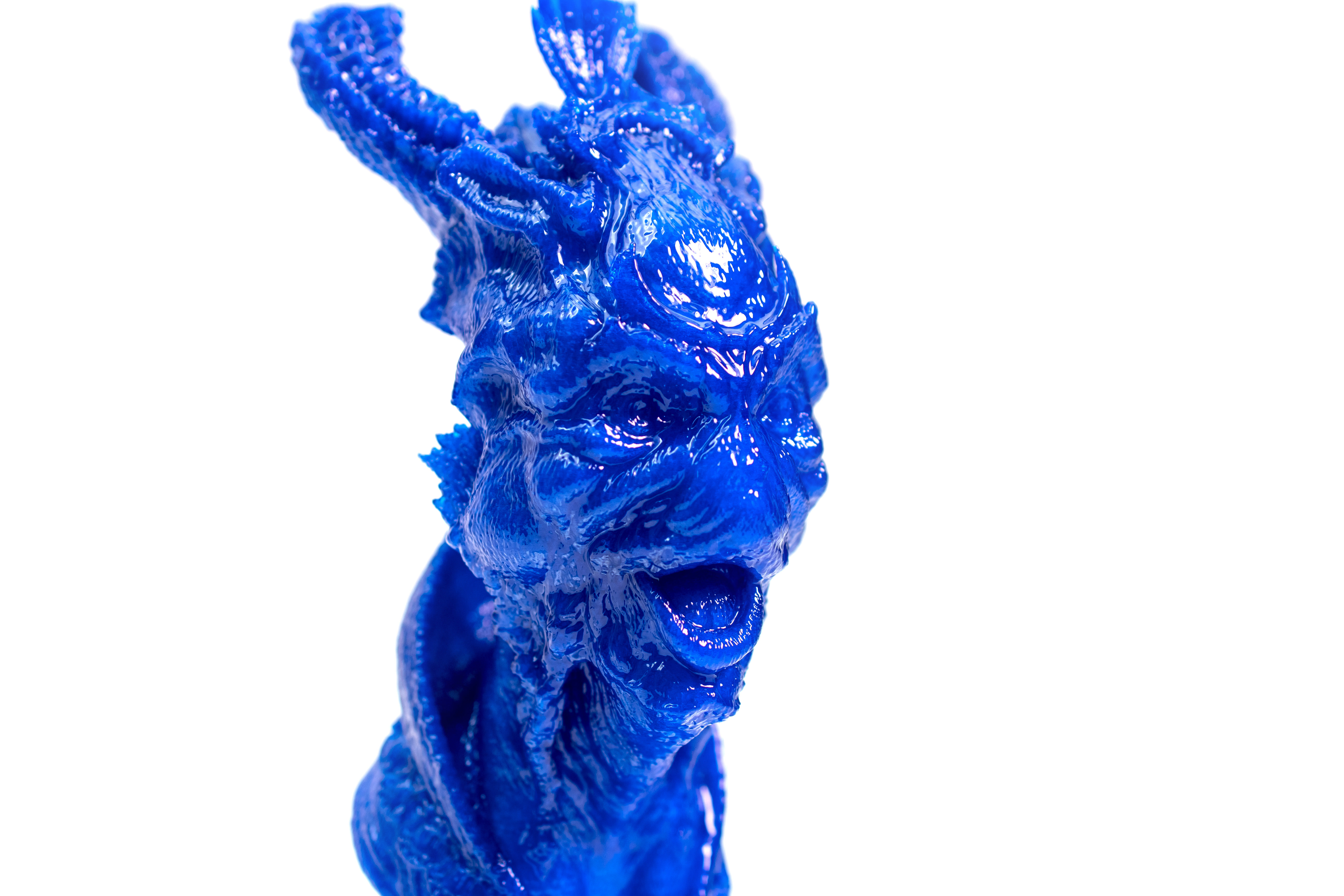

| Masks and other design parts | Miniatures |