Basic info

Description

Polycarbonates (PC) are a group of polymers excelling in their tenacity, tensile strength, and temperature resistance. Outside of the 3D printing world, they are used for example for making CDs, protective glasses and shields, or car headlight covers.

Pure polycarbonate is not suitable for 3D printing because of its bad surface adhesion and significant thermal expansion. Prints tend to deform and crack. For this reason, various additives are usually added to improve printability. The result of our own development is the Prusament PC Blend. It has relatively great printability and is suitable for making technical parts with high mechanical and temperature resistance.

The main disadvantage of most polycarbonates is that they’re extremely hygroscopic (they absorb moisture). They should be stored in airtight containers with desiccant (silica gel) and should be dried in the oven prior to printing.

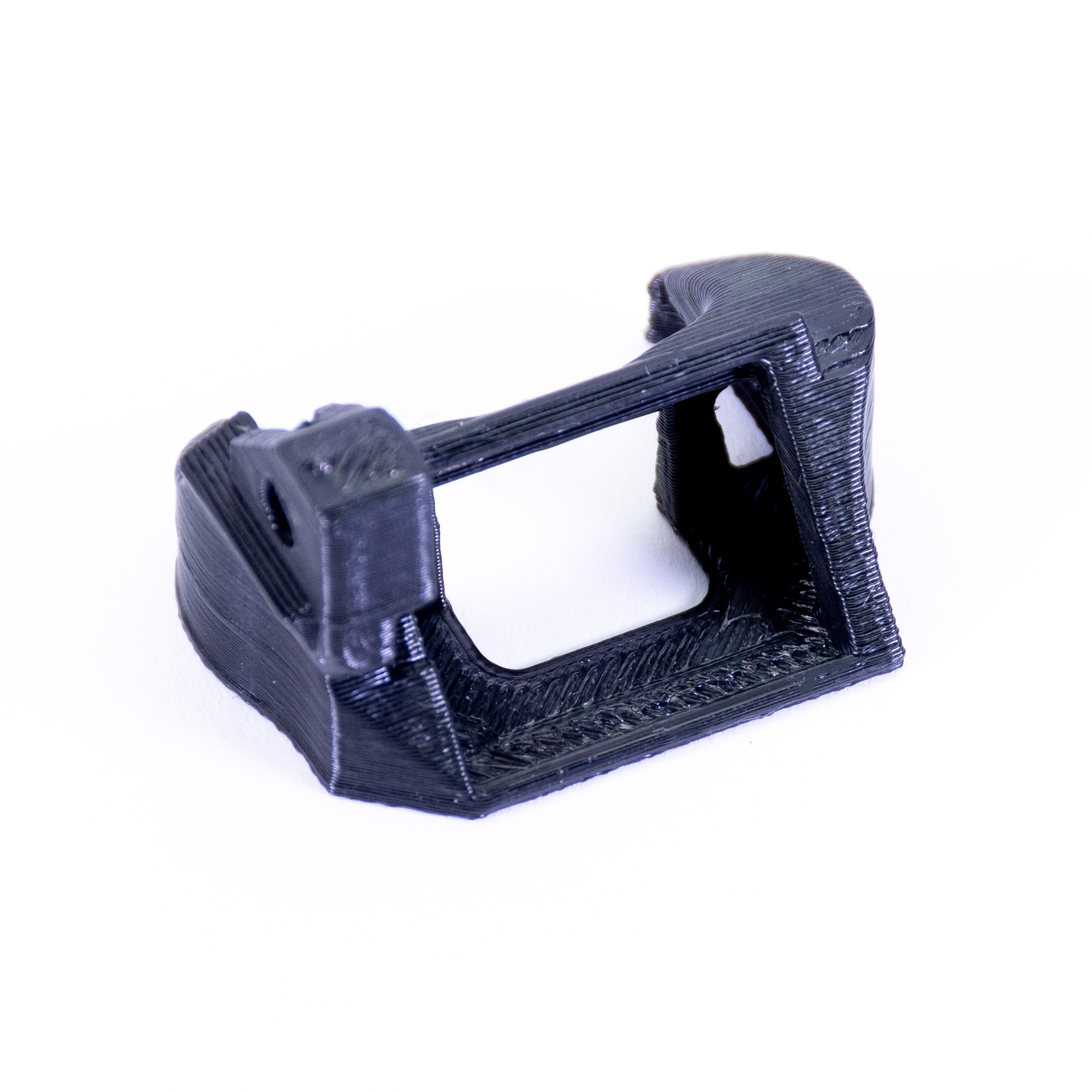

Some manufacturers counter this with various additives, for example, Prusament PC Blend tends to absorb moisture much less than other polycarbonates. Because of its high-temperature resistance, PC is a suitable material for printer fan shrouds.

Polycarbonate requires some experience to print properly. If you are a beginner, consider experimenting with easier materials like PLA or PETG first.

To compare supported material properties, see our material table.

|

Pros |

Cons |

|---|---|

|

✔ High-temperature resistance |

✖ Pure polycarbonate is highly hygroscopic |

|

✔ High impact tenacity and tensile strength |

✖ High nozzle and bed temperature |

|

✔ Pure polycarbonate is transparent |

✖ High warping, especially with large models |

|

✔ Good electric insulation properties |

✖ Moderate odor during printing |

|

✖ Application of a separation layer is recommended | |

|

✖ High price |

Best use

The best use of PC is for printing technical parts requiring great heat and mechanical resistance.

Tips for successful printing

Consider using an enclosure

Printing polycarbonate is often tricky, as it tends to warp a lot, even with the additives. Printing inside an enclosure helps. Polycarbonate needs to be printed on a special surface, for example, a powder-coated sheet with a glue stick, PEI, or Build-tak. For small to medium objects, you can increase infill to >25% and add more top layers (4 or more) for a stronger print. However, this is not recommended for large prints, where we recommend reducing this.

It is also possible to make your own enclosure.

Use a Skirt in PrusaSlicer

If you don’t have a printer enclosure, we suggest placing the object in the middle of the printing platform and setting the skirt value as high as possible. This will make a microclimate with a slightly higher temperature around the model and increase your chances for a successful print.

Add Brim around small objects

You should use the Brim function for printing parts with a small contact area with the print surface.

Try to avoid warping

Polycarbonate is not suitable for printing large objects covering the whole sheet. Prints with round edges warp less than those with sharp edges (this is true for any type of filament). Warping is also affected by infill density and the number of perimeters. Denser infill (and more material inside the object in general) increases warping - and a risk of separation from the print surface. A lesser number of perimeters increases the chances of a successful print of large polycarbonate models.

Do not print in cold areas

In some cases, the printer might show a “Bed thermal runaway” error. This typically occurs with ambient temperatures below 18 °C when the printer cannot hold the high heatbed temperature.

Careful print preparation is a key

Prusament PC Blend is easy to print compared to other polycarbonates. Print preparation is also quite easy. Recommended nozzle and bed temperatures are 275±10 °C and 110 ±10 °C. PC Blend is printable on the powder-coated TXT sheet if you apply glue stick on it. If you print without a glue separation layer, you risk damaging the print sheet. This issue was moderated with the powder-coated satin sheet. This surface doesn't need any separation layer if you print with PC Blend occasionally. If you print with polycarbonate regularly, we still suggest using glue stick to keep your satin sheet in the best shape possible.

Sample prints

|  |

| Pulley linear bearings | Fan shroud |

|  |

| Water angle valve lever | Air filter cover |

|  |

| Battery pack | Hinges |