To achieve good quality prints, it is fundamental that the nozzle can make the right amount of contact with the print surface. In case this is not achieved, the printer will show the message "nozzle cleaning failed".

How to fix it

Nozzle cleaning

Check if the nozzle has residue. Debris on the nozzle or heater block can affect its thermal properties. To clean it, heat the nozzle for three to five minutes at 250 °C, as the remains of the filament must be warmed up slightly so that they can be removed more easily.

Use a small brass brush to clear away any old plastic stuck on the nozzle and heaterblock.

Caution: the printer is still at a hot temperature! Wait until the hot parts are cooled down to ambient temperature. It takes approximately 10 minutes.

Steel sheet cleaning

Make sure that the steel sheet is clean of any residue. For the smooth, textured, or satin sheet, clean with 90% or higher percentage isopropyl alcohol (IPA).

Check if the nozzle is not loose

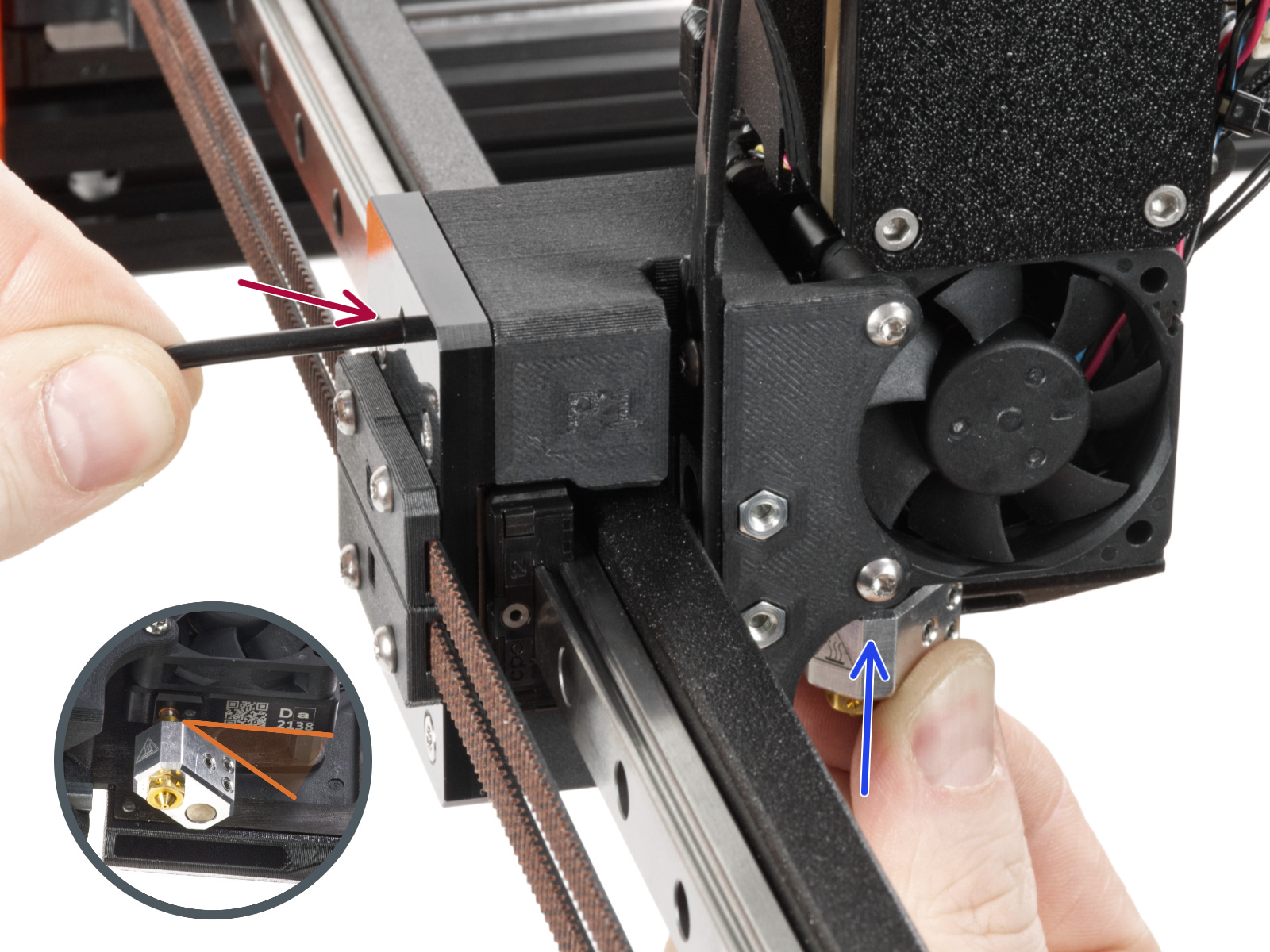

On single-tool XL, after removing the x-carriage cover, hold the heater block (make sure that the nozzle is not heated!), and use the Torx TX8 key as shown in the picture to tighten the set screw. Do not use extra force while tightening, it may damage the hotend tube. The nozzle must be approximately at a 35°-40° angle to avoid damaging the hotend cables.

|  |

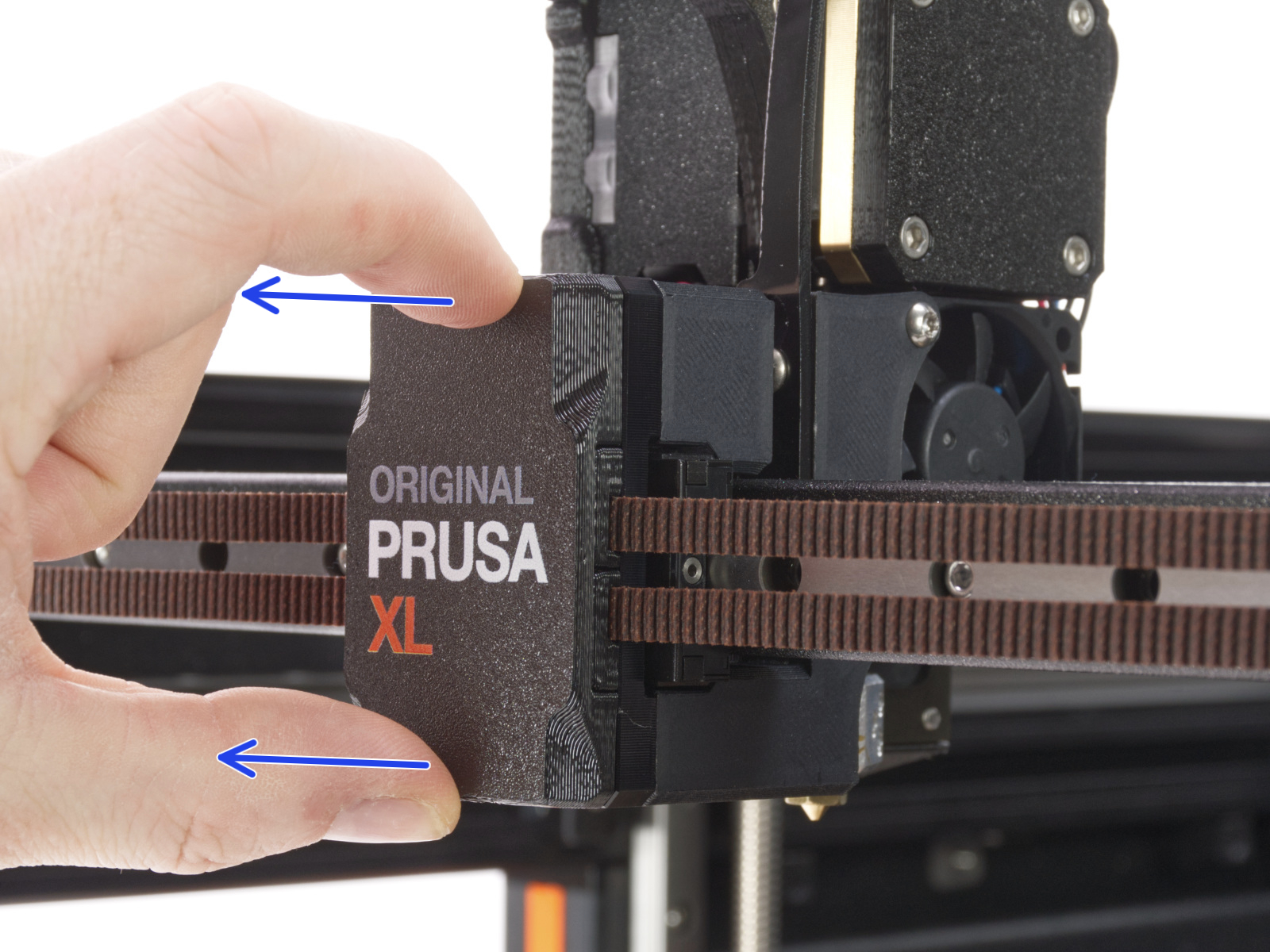

On multi-tool XL, identify the tool that has the nozzle to be checked, and park it. Hold the heater block (make sure that the nozzle is not heated!), and use the Torx TX8 key in the part shown in the picture to tighten the set screw. Do not use extra force while tightening, it may damage the hotend tube. The nozzle must be approximately at a 35°-40° angle to avoid damaging the hotend cables.

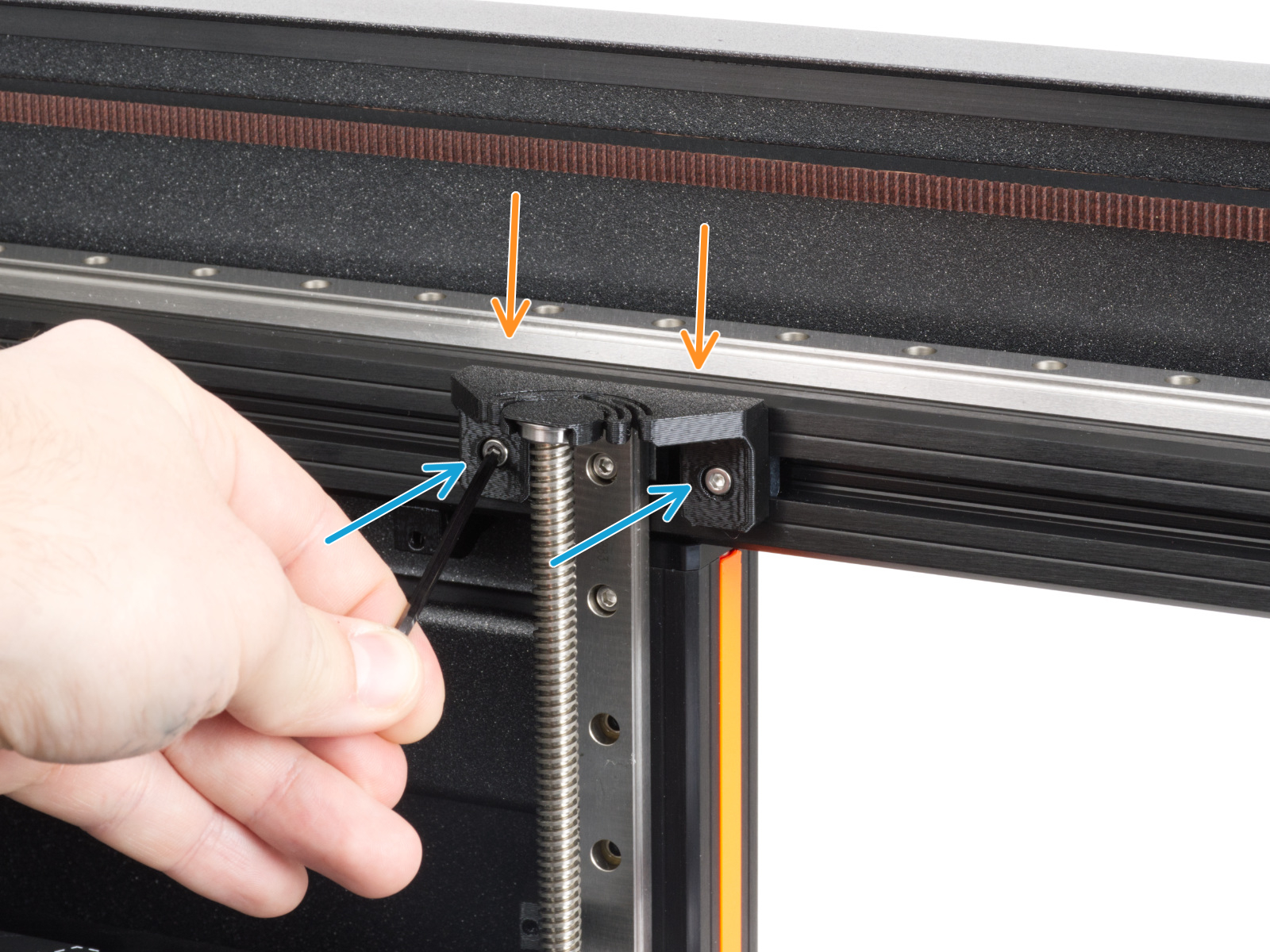

Check the Z-axis bearing housing

The Z-axis bearing housings are the end-stop for the Z-axis. It is important to have a tiny clearance between the Z-axis bearing housings and the heatbed frame when the printer is at the top position.

This way, during the mesh bed leveling and the autohome procedures, there can be an ideal amount of tiny contact between the nozzle and the print surface.

Too small of a clearance can cause the Nozzle Cleaning Failed warning message to appear. In this case, in order to achieve the ideal clearance, slightly loosen the bolts holding the bearing housings in place.

If the warning message still appears, sightly loosen the mentioned bolts once again, keeping in mind to still have the Z-axis bearing housings reasonably tight and held in place.

Once you find an ideal tightness for the bolts that works and holds the Z-axis bearing housings in place, keep the change permanently.