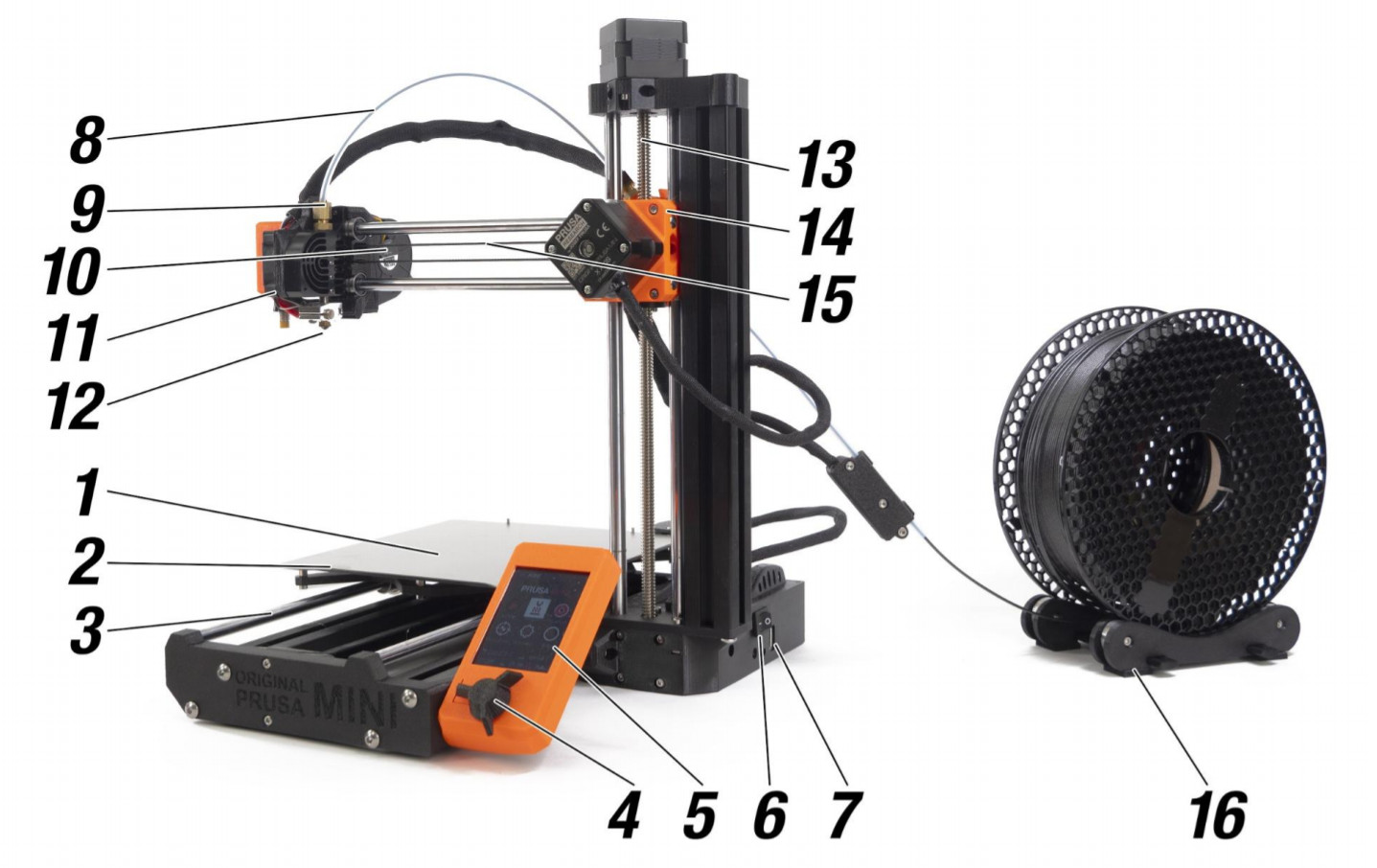

3D printers have their own vocabulary and words for describing their various parts and functions. If you are doing maintenance or about to seek help online, it is necessary to have the right words to describe your issue or problem. We have put together a list of words with explanations, covering most parts on the printer.

Be aware that there are some differences in terminology between the MINI and the MK3/S

- Spring steel sheet - comes in two variants, smooth and textured. This is where the printed

object appears. Please read the maintenance instructions carefully to ensure optimal conditions

for 3D printing. - Heatbed - located directly under the spring steel sheet. Heatbed ensures good adhesion of the

printed object. Warning: do not touch the heatbed when it’s hot! - Y-Axis - the general name for the entire heatbed assembly (smooth rods, belt, heatbed…).

- Knob - main control of the Original Prusa MINI 3D printer: rotate left/right to scroll through options and press the knob to confirm your selection. There’s a reset switch directly next to the

knob. Press it to perform a hard reset. - LCD screen - the display is used for the configuration of the 3D printer.

- Power switch - when the printer is not in use, turn it off using the power switch.

- USB port - compatible with USB 2.0/3.0 flash drives (FAT32 filesystem). Used for reading

print files (G-Codes) from the inserted drive and flashing the firmware. - Main PTFE tube (Bowden-tube) - leads the filament strand from the extruder into the print head/nozzle.

Inspect it from time to time to make sure there is no debris inside that would prevent the

filament strand from reaching the nozzle. - Tube fitting - on both ends of the main PTFE tube. In case filament gets stuck in the PTFE

tube, use a spanner (included with the printer) to remove the fittings and the PTFE tube to get

access to the filament strand. - Print fan - cools the printed object, and improves print quality. Comes with RPM monitoring.

- Print head - Lightweight print head consisting of the hotend (printing nozzle), M.I.N.D.A. sensor, and two fans. The heaviest parts of the extruder were moved onto the Z-axis tower to improve

print quality. - Nozzle - 0.4mm nozzle, can be replaced with e.g. 0.25mm or 0.6mm E3D-compatible nozzles

to achieve various effects. - Z-Axis - the entire vertical axis assembly (smooth rods, Z-axis motor…).

- Extruder / Extruder motor - as opposed to 3D printers like MK2 or MK3S, the extruder motor

is not moving along the X-axis. Instead, it’s fixed on the side and pushes filament through the

PTFE tube towards the print head. - X-Axis - allows the movement of the belt-driven print head from left to right.

- Spool holder - should be placed near the printer, so the filament strand can enter the PTFE

tube from below. The filament must not bend at an acute angle.

Additional terms

M.I.N.D.A. sensor - Induction sensor for auto-leveling.

You can identify all parts of the Original Prusa MINI using the 360 viewer.