The materials used for FFF 3D printing are mostly hygroscopic. This means that they readily attract water molecules from the environment they are in. When used for printing, a material that has gathered humidity might not behave as expected.

Prevention

Some filaments are more hygroscopic than others. When using a new material, make sure to research its properties and the best way to store it. It is best to avoid having to dry the filament if possible.

It is best to store your filaments in a closed space or box, with some desiccant material in it. If you have limited availability for this type of storage, prioritize storing filaments that are more hygroscopic. PLA, for example, doesn't change properties too much by uptaking humidity, whereas Polyamide is affected quite significantly.

You can purchase a box with the specific purpose of keeping the filament dry, or make your own.

Another popular solution to keep your filament dry is using vacuum bags for storage. There are bags specific for filaments, but you can use any that will fit a filament inside. Keep a desiccant in the bag when storing the filament.

Multi-Tool Printing

In printers like the Original Prusa XL, where filament is loaded directly into toolheads any humidity in the filament is critical. When printing with multiple toolheads, the unused tools remain heated (the idle temperature is set to 70°C by default). If the filament is wet, moisture is released into the tool, causing stringing in the toolhead. In such cases, even PLA can absorb enough moisture to create printing issues. This makes the XL more susceptible to filament moisture compared to single-tool printers, therefore we recommend drying the filament for printing on the Original Prusa XL.

How to recognize if the filament has gathered humidity

In case a material is affected by humidity, the general first signal will be a poor quality of the model surface.

In some cases, the high content of water in filament can cause low layer adhesion, blobs on the prints, and bubbling and smoke during extrusion.

Polyamide, PVA, and TPU (Flex) are filaments more commonly in need of drying than more popular filaments like PLA.

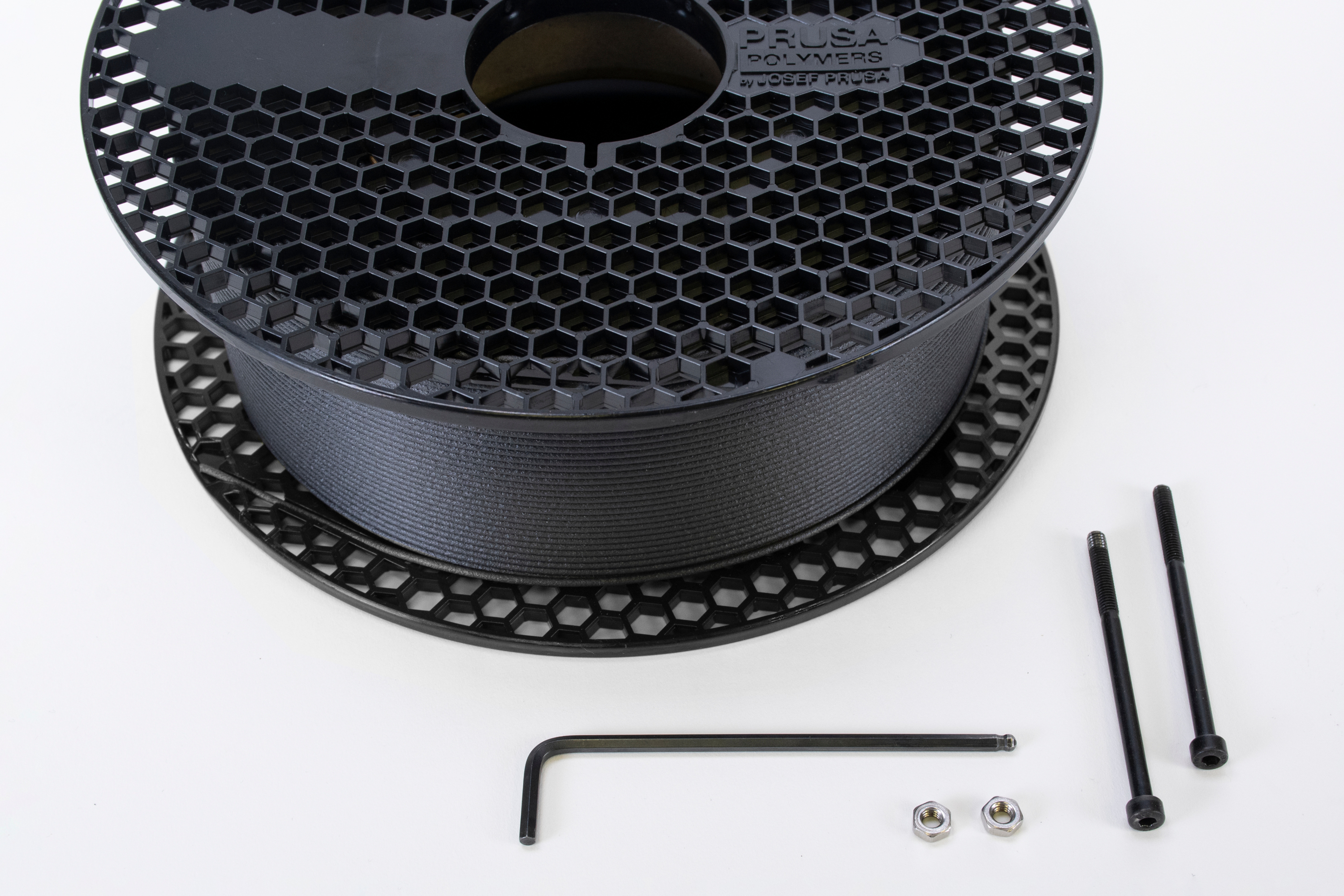

Prusament black spool

The black plastic sides of Prusament spools are firmly pressed into the cardboard cylinder. The plastic sides expand with rising temperature and cause the expansion of the cardboard center as well. When the temperature decreases plastic shrinks back to its original shape but the cardboard stays expanded which causes loosen spool. The spools can be heated up safely up to 45 ºC without this happening.

Alternatively, it is possible to add a screw holding the two sides of the plastic together. The screw needs to have a thread of at least 65 mm. In the pictures, we use an M4x65 screw, tightened by a 3.5mm Allen key.

After heating up the spool to above 45 ºC, the screw will need to be in the spool until the end of its use, or else the spool will fall apart.

|  |

|  |

Prusament Grey spool

The Prusament spools with grey plastic sides are also pressed to the cardboard center, but they are also glued. The glue added can withstand up to 90 ºC. So there is no need to add the screw to dry this spool if this temperature is not exceeded.

The PA11CF filament uses the grey Prusament spools. It is recommended to keep this filament in a dry box between each use, even if the filament will be used soon. In case that is not possible, dry the filament before each use.

Drying methods

Temperatures

Once we are sure that the spool will not fall apart, the following temperatures and times are recommended for the Prusament materials. It is important not to exceed these temperatures while drying the filament, or the filament will soften and stick together.

| Material | Temperature | Time |

|---|---|---|

| PLA | 45 ºC | 6 hours |

| PVB | 45 ºC | 8 hours |

| PETG | 55 ºC | 6 hours |

| ASA | 80 ºC | 4 hours |

| PC | 85 ºC | 5 hours |

| PCCF | 95 ºC | 4 hours |

| PA11CF | 90 ºC | 6 hours |

Filament dryer

There are specialized boxes that will not only keep filaments dry but also actively remove the moisture from filaments. Usually, you are also able to keep the filament in the box while printing.

Make sure to check the specifications of the box you intend to use to make sure that it matches the drying temperature of your filament.

Oven

Since most people have an oven at home, this seems the easiest way to dry filament. However, some things need to be noted for filament drying in a conventional oven.

Home ovens don't have a very precise temperature measurement. The fluctuations that do not affect your food might damage your filament, especially low-temperature ones like PLA. If using an oven, make sure to have an external thermometer to correct the temperature if necessary.

Another issue is that a lot of home ovens cannot be set at a temperature low enough to dry the filaments without damaging them. Even if left for less time than recommended, high temperatures will damage the filament.

Food dehydrator

A different method of drying is adapting a food dehydrator to fit a filament spool inside. The adaptation is usually achieved by taking off the trays between the layers and placing the filaments inside. These dehydrators usually have only low temperatures, so check the drying temperature of your filament before purchasing one.